| Tweet |

Custom Search

|

|

|

||

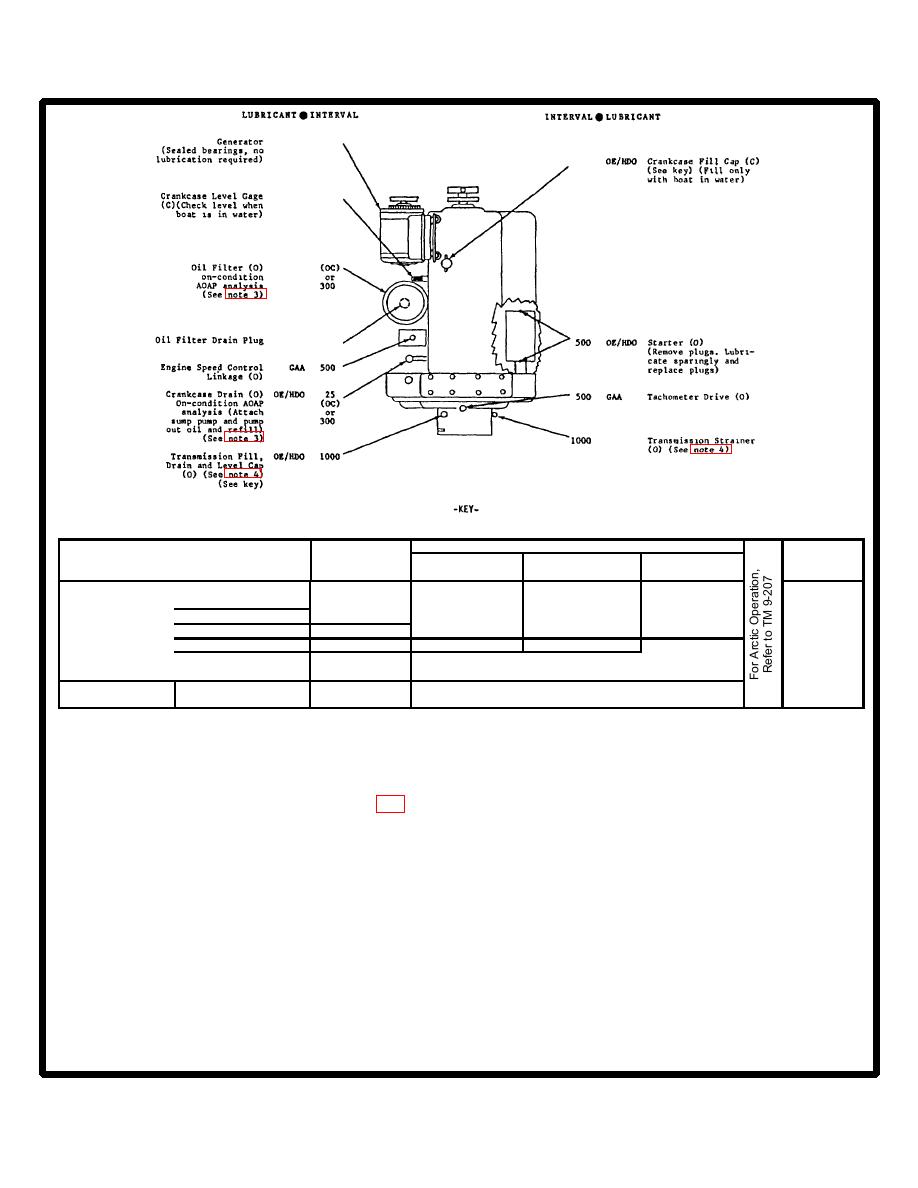

LO 5-1940-221-12

note 3

note 3

note 4

note 4

EXPECTED TEMPERATURES

Above +32F

+ 40 F to -10 F

0 F to -65 F

CAPACITY

(Above -0)

(5 to -23)

(-18 to -53)

INTERVALS

OE/HDO

LUBRICATING OIL,

(MIL-L-2104C)

Engine

Intervals

Crankcase Oil

9.5 qt (10L) ea

OE/DO 30

given are

Transmission Oil

3 qt (2.8L) ea

in hours

Oil Can Points

OE/HDO 30

OR/HDO 10

OEA

of normal

OEA/APG-PD1

LUBRICATING OIL,

operation

(MIL-L-46167)

Engine Sub-Zero

GAA

GREASE,

(MIL-G-10924)

Auto and Artillery

ALL TEMPERATURES

NOTES:

5. STEERING QUADRANT. Eve ry 250 hours clean old

1. FOR OPERATION OF EQUIPMENT IN PROTRACTED

grease from grease cups and relubricate grease cups and

COLD TEMPERATURE BELOW -10F (-23C).

Remove

fittings with GAA.

lubricants prescribed in the key for temperatures above -10F

6. DO NOT LUBRICATE. Propeller shaft, propeller strut

(-23C). Clean parts with SOLVENT, dry-cleaning (SD-II).

bearing, and rubber shaft bearings.

Relubricate with lubricants specified in the key for

7. MANUAL BILGE PUMP.

Lubricate with silicone

temperatures below -10F (-23C).

compound, NSN 9150-00-076-1474, 1/2 oz container every

2. OIL CAN POINTS.

Every 100 hours, lubricate

1000 hours.

transmission shift linkage, pins, and clevises, and all exposed

adjusting threads with OE/HDO.

Copy of this lubrication order will remain with the vehicle at all

3. CRANKCASE OIL AND FILTERS. Replace on-condition

times. Instructions contained herein are mandatory.

as directed by the Army Oil Analysis Program (AOAP)

laboratory. Send a sample of oil for analysis at intervals of 25

By Order of the Secretary of the Army:

hours or 30 days. Refer to TB 43-0210 for sampling. When

JOHN A. WICKHAM, JR.

AOAP laboratories are not available, replace the oil and filters

General, United States Army

at the hard-time interval of 300 hours or 6 months. Operate for

Official:

Chief off Staff

5 minutes, check for leaks, check oil level, and bring to full

ROBERT M JOYCE

mark.

Major General, United States Army

4. TRANSMISSION REDUCTION GEAR. Drain by pumping

The Adjutant General

oil from unit. Disconnect hose. Remove strainer, clean, and

replace. Fill transmission. Start engine, run at idle for three

DISTRIBUTION:

minutes, stop, check for leaks, check oil level and bring to full

To be distributed In accordance with DA Form 12-25D,

mark.

Operator Maintenance Requirements for Boat Bridge Erection.

I U.S. GOVERNMENT PRINTING OFFICE: 1985-461-026/20301

CARD 2 OF 2

|

||

|

||