| Tweet |

Custom Search

|

|

|

||

LUBRICATION ORDER

LO 55-1905-223-12

1 MAY 2006

(Supersedes LO 55-1905-223-12 6 APRIL 1992)

LANDING CRAFT, UTILITY

(LCU-2000 CLASS)

NSN 1905 -01-154-1191

Reference TM 55-1905-223-10, TM 55-1905-223-24-Series.

Reporting Errors and Recommending Improvements

You can improve this publication. If you find any mistakes or if you know of a way to improve the procedures, please let us know.

Submit your DA Form 2028 (Recommended Changes to Equipment Technical Publications) through the Internet on the Army

Electronic Product Support (AEPS) Web site. The Internet address is https://aeps.ria.army.mil. The DA Form 2028 is located under the

Public Applications section on the AEPS public home page. Fill out the form and click on SUBMIT. Using this form on the AEPS site

will enable us to respond quicker to your comments and to manage the DA Form 2028 program better. You may also mail, fax, or e-

mail your letter or DA Form 2028 directly to: AMSTA-LC-LMIT/TECH PUBS, TACOM-RI, 1 Rock Island Arsenal, IL 61299-7630. The

e-mail address is TACOM-TECH-PUBS@ria.army.mil. The fax number is DSN 793-0726 or Commercial (309) 782-0726.

Approved for public release: Distribution is unlimited

Intervals (on condition or hard time) and the related task-hour times are based on normal operations. The task-hour time specified is

the time you need to do all the services prescribed for a particular interval. On-condition (OC) oil sample intervals shall be applied

unless changed by the Army Oil Analysis Program (AOAP) laboratory. Change the hard time interval if your lubricants are

contaminated or if you are operating the equipment under adverse operating conditions, including longer-than-usual operating hours.

The hard time interval may be extended during periods of low activity. If extended, adequate preservation precautions must be taken.

Hard time intervals will be applied in the event AOAP laboratory support is not available.

Clean fittings before lubricating. Clean parts with dry CLEANING SOLVENT (SD), type II or equivalent. Relubricate all areas

exposed to water after vessel operation.

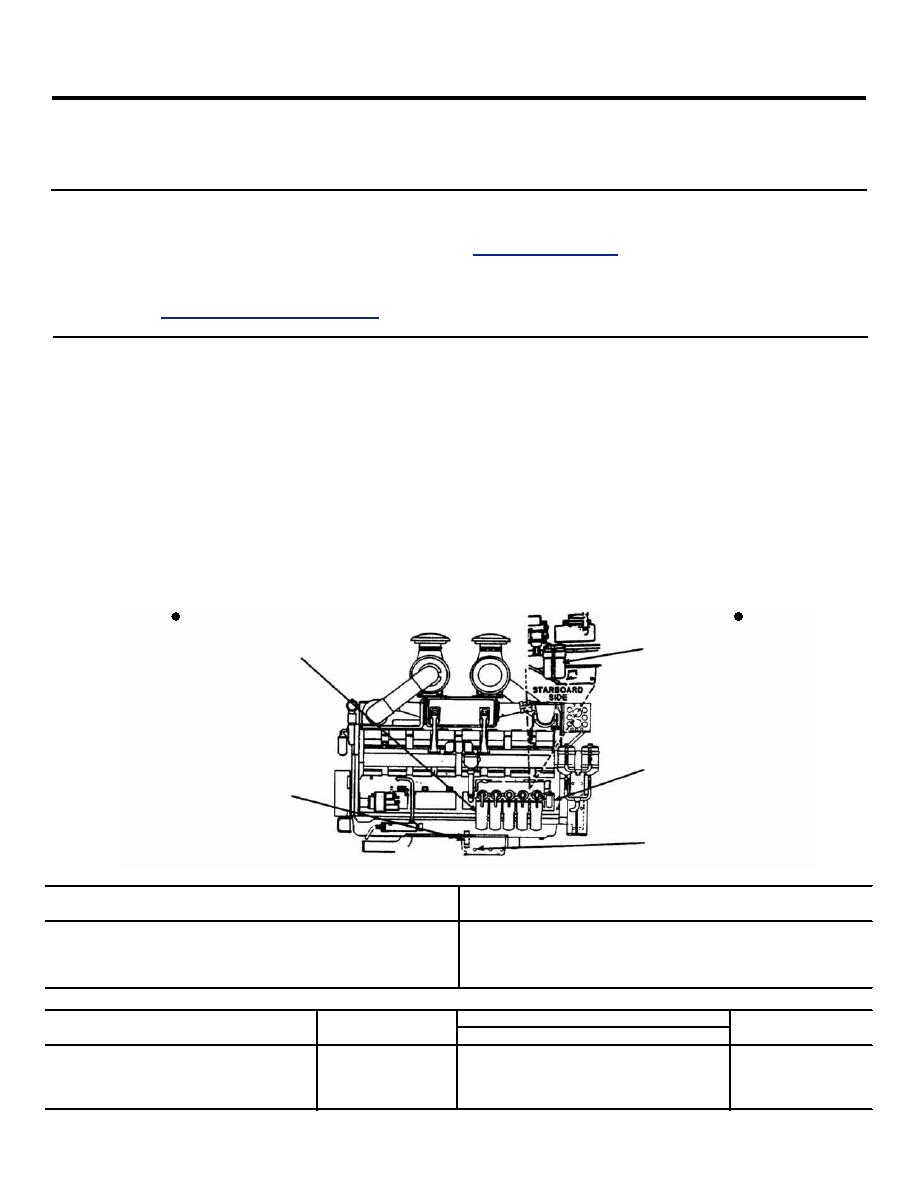

Dry before lubricating. Dotted arrow points indicate lubrication on both sides of the equipment.

Level of maintenance. The lowest level of maintenance authorized to lubricate a point is indicated by one of the following: (C)

Operator/crew; (O) Unit Maintenance.

For arctic operation refer to FM 9-207.

*The time specified is the time required to perform all services at the particular interval.

LUBRICANT INTERVAL

INTERVAL LUBRICANT

OC

OC

OE/HDO

Engine Oil

250

Engine Oil

OE/HDO

250

Bypass Filter

Filter (Remove

(Remove, Replace)

Replace, Clean)

(See Note 1)

(See Note 1)

(C)

(C)

OE/HDO

Crankcase Oil

S

Fill Cap

Crankcase Oil

OE/HDO

250

(C)

Level Gauge

D

(Check Level)

(See Note 2)

OE/HDO

Crankcase Oil

(C)

Drain

S

(Drain, Refill)

250

PORT

SIDE

(See Notes 3,4)

KTA50 MAIN PROPULSION ENGINE

(C)

TOTAL TASK-HOURS*

TOTAL TASK-HOURS*

INTERVAL

TASK-HOURS

INTERVAL

TASK-HOURS

S OR 250

1.0

D

0.1

OC OR 250

1.0

-KEY-

EXPECTED TEMPERATURES

INTERVALS

CAPACITY

ALL TEMPERATURES

D-Daily

Lubricating oil,

OE/HDO

S-Semiannually

55 gallons

15W/40

(MIL-PRF-2104) internal combustion

(6 months)

engine, tactical service

OC-On Condition

Card 1 of 41

|

||

|

||