| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-14

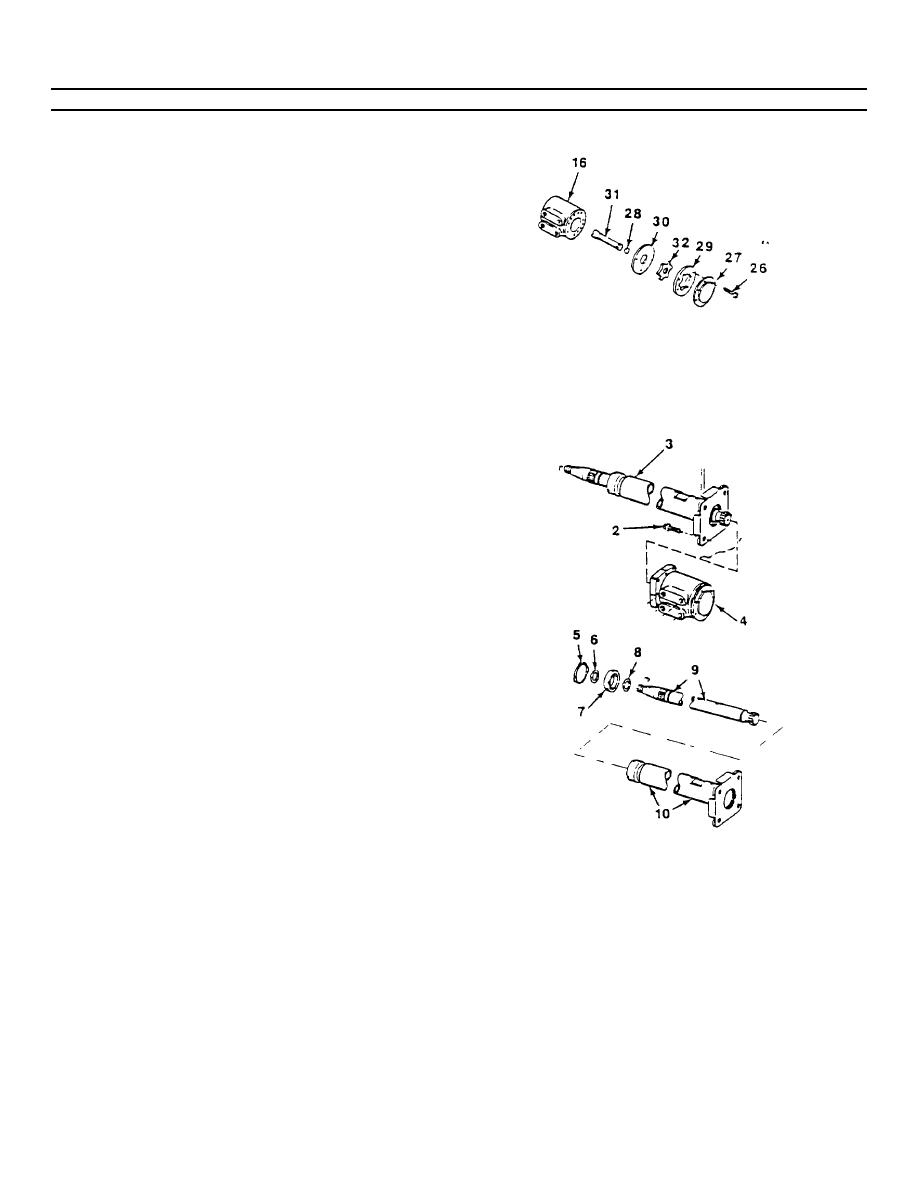

REPAIR HELM UNIT (Continued).

b.

Place the splined end of the drive shaft (31)

within the meter gear star (32) so that the slot at

the control end of the drive shaft is in

alignment with the valleys between the meter

gear teeth. Push the splined end of the drive

shaft (31) through the meter gear star (32) so

that the spline extends about one half its length

beyond the meter gear star.

c.

Install the drive shaft and meter gear star

assembly onto the housing so that the meter

gear star (32) fits into the meter gear (29).

d.

Rotate the meter gear star (32) slightly to

bring the cross slot of the drive shaft (31) into

engagement with the centering pin.

e.

Install the spacer (28) in :he slot of the meter

gear star (32) so that it is flush with the gear

surface. (If the spacer does not drop flush with

the gear surface, the drive has not properly

engaged the centering pin.

f.

Install the end cap (27) and secure with six

capscrews (26). Torque evenly to 150 pound -

inches.

3.

ASSEMBLE AND INSTALL SHAFT AND FLANGE

ASSEMBLY.

a.

Install retaining ring (8), bearing (7) and

retaining ring (6 and 5) onto shaft (9).

b.

Install shaft assembly into flange unit (10).

c.

Install shaft and flange assembly (3) into the

control and metering assembly (4).

d.

Secure unit with four mounting bolts (2).

6-79

|

||

|

||