| Tweet |

Custom Search

|

|

|

||

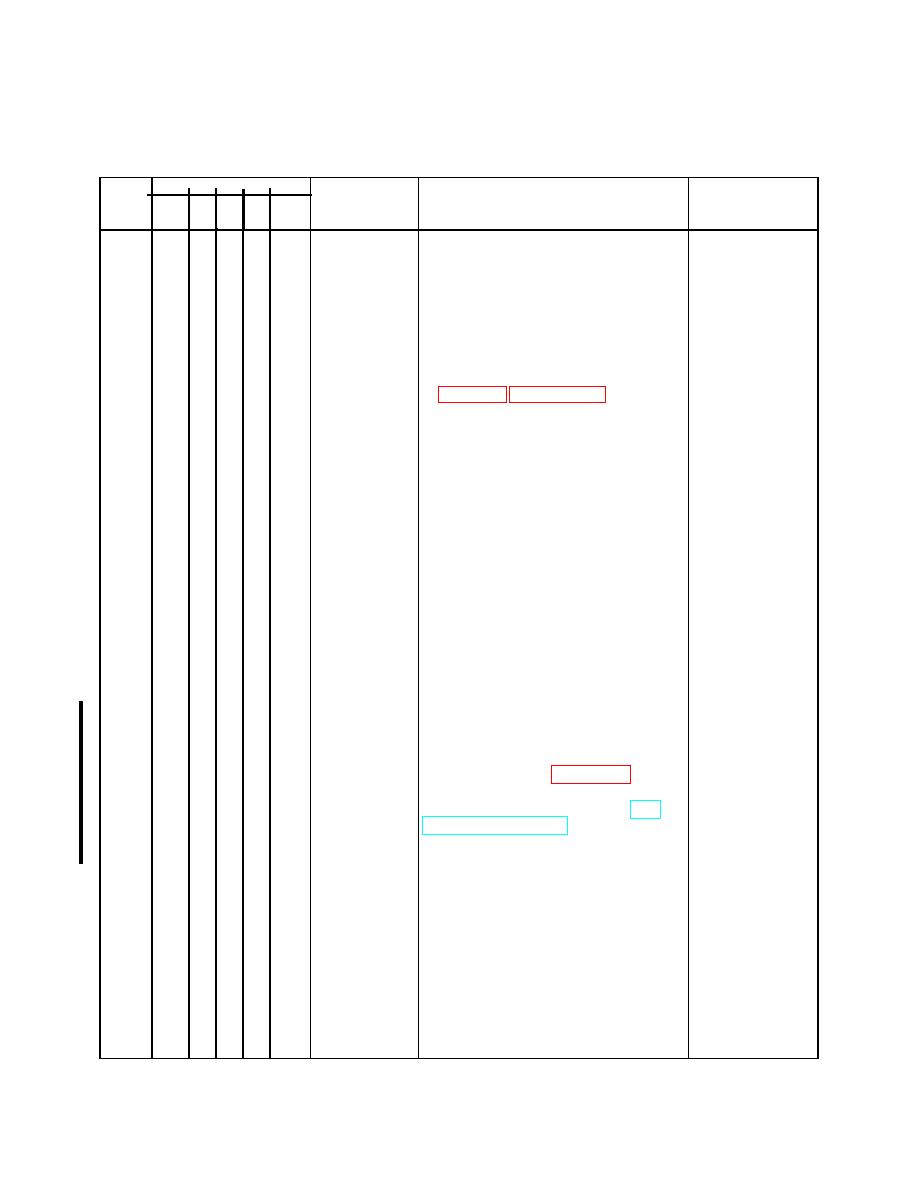

TM 55-1905-223-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Service CONT

B Before

D During

A After

W Weekly

M- Monthly

INTERVAL

PROCEDURES

EQUIPMENT IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO.

B

D

A

W

M

INSPECTED

OR ADJUSTED AS NECESSARY

AVAILABLE IF:

56

Emergency

cont.

Temperature

Check gauge for proper operating

Cooling

●

more than 196F

coolant temperature (170 to 195F).

System

Check that all switches are in proper

Switches

●

positions. Refer to Chapter 2, Section

Check that battery charger is recon-

Battery

●

nected if previously disconnected.

Charger

notify engineer on watch. Ammeter

should read near 0 for a trickle

change. If the reading is above 3

AMPs, refer to unit maintenance.

Class III

Visually inspect tank for leaks.

Emergency

57

●

leakage.

Generator

Day Tank

Any part is

Visually inspect exterior of switch-

Emergency

58

●

●

missing or

board for damaged or missing circuit

Switchboard

meters are un-

breakers, meters, controls or lights.

serviceable.

NOTES

Not applicable to vessels with FM-

200 Fire Suppressant System in-

stalled. Reference para. 2-46 and

2-47 for FM-200 and Water Wash-

down System operation. Ref. TM

55-1905-243-24&P for maintenance

and installation of FM-200

components.

Part of the system is located in the

Air Conditioning and Emergency

Generator Room with the remain-

der in the Engine Room.

During periods of extreme heat, fire

Engine Room

59

●

●

extinguishers may release a portion of

HALON 1301

their charge through the discharge

Fire Suppres-

nozzles. Visually inspect nozzles for

sion System

evidence of discharge or leaks.

Change 10

|

||

|

||