| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

h.

Repair consists of replacement of defective parts.

REPLACEMENT

NOTE

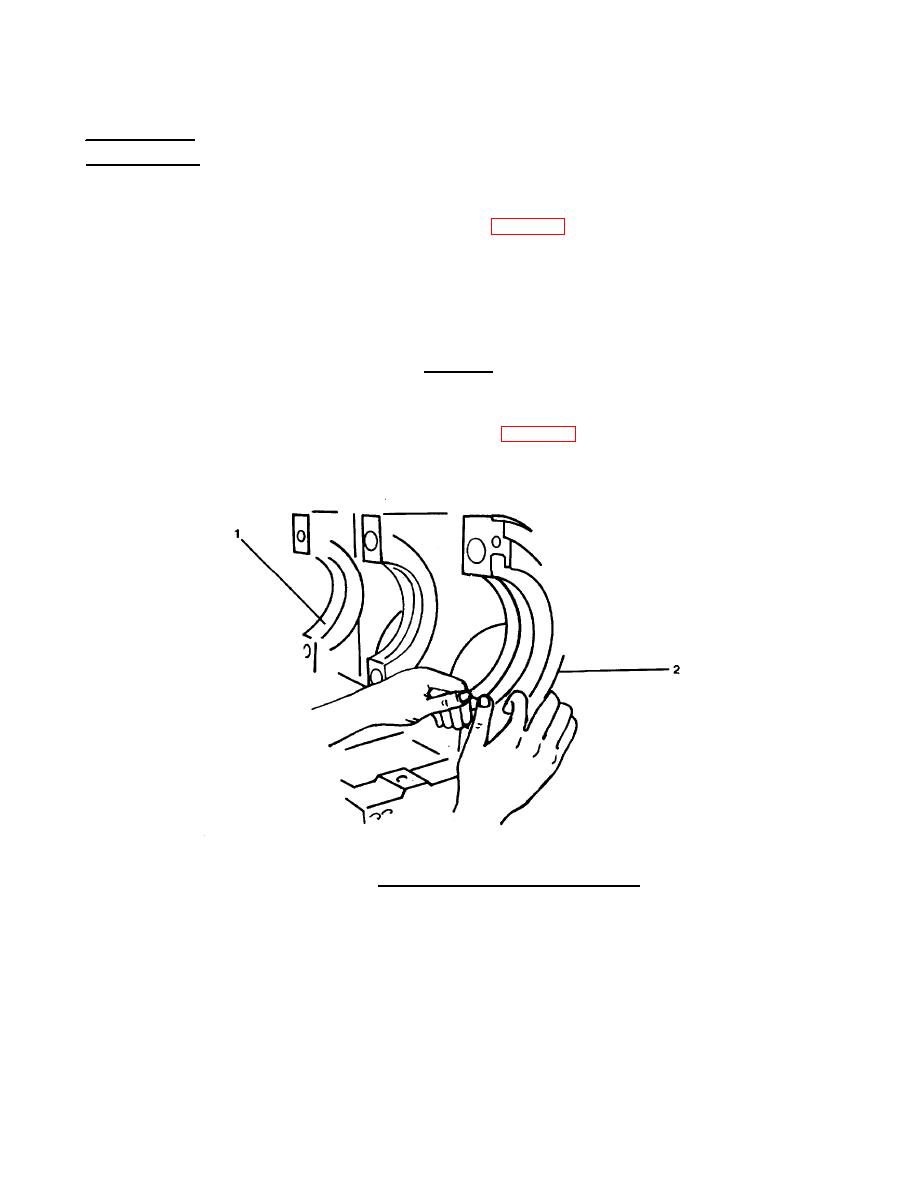

Before installation, check the bearing sizes (FIG. 4-54 and 4-55). Main bearings

are two widths; the narrow bearings fit locations 1 and 9. The upper bearings

contain an oil hole, the lower bearings do not. Both are marked on the back to

indicate location.

a.

Be sure the crankshaft, main bearing shells, thrust bearing retainer, and blockmain bearing bore are

clean. Use a lint-free cloth to clean as necessary.

CAUTION

Prevent dirt from mixing with the lubricant. Dirty lubricant causes equipment failure.

b.

Place the new upper main bearing shells (sleeves) (1, FIG. 4-56) in the block (2). Align the tang in

the bearing with the slot in the block. The ends of the bearing shell (1) must be flush with the parting

face of the block (2).

FIGURE 4-56. Main Bearing Shell (Sleeve) Installation.

4-50

|

||

|

||