| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

(1)

Visually inspect the housing for cracks or damage, and replace if necessary.

(2)

Visually inspect the assembled washer screw holes in the housing for damaged threads.

(3)

Visually inspect the straight shaft bore. Remove any burrs or sharp edges with emery cloth.

(4)

Measure the straight shaft bore in the housing. If the inside diameter exceeds 1.1246 in. (28.565

mm), replace the housing.

b.

Clean the shafts and inspect as follows:

(1)

Use solvent to clean the shaft.

(2)

Dry with compressed air.

(3)

Visually inspect the shaft for cracks or damage.

(4)

Visually inspect the thread condition of the shaft internal threads.

(5)

Measure outside diameter in the center and each end of the shaft. The measurement should be

between 1.122 inch (28.50 mm) and 1.124 inch (28.55 mm).

(6)

Replace the shaft as necessary.

c.

Clean the engine poppet valve rocker arms and injector rocker levers wi h solvent and inspect as follows:

t

(1)

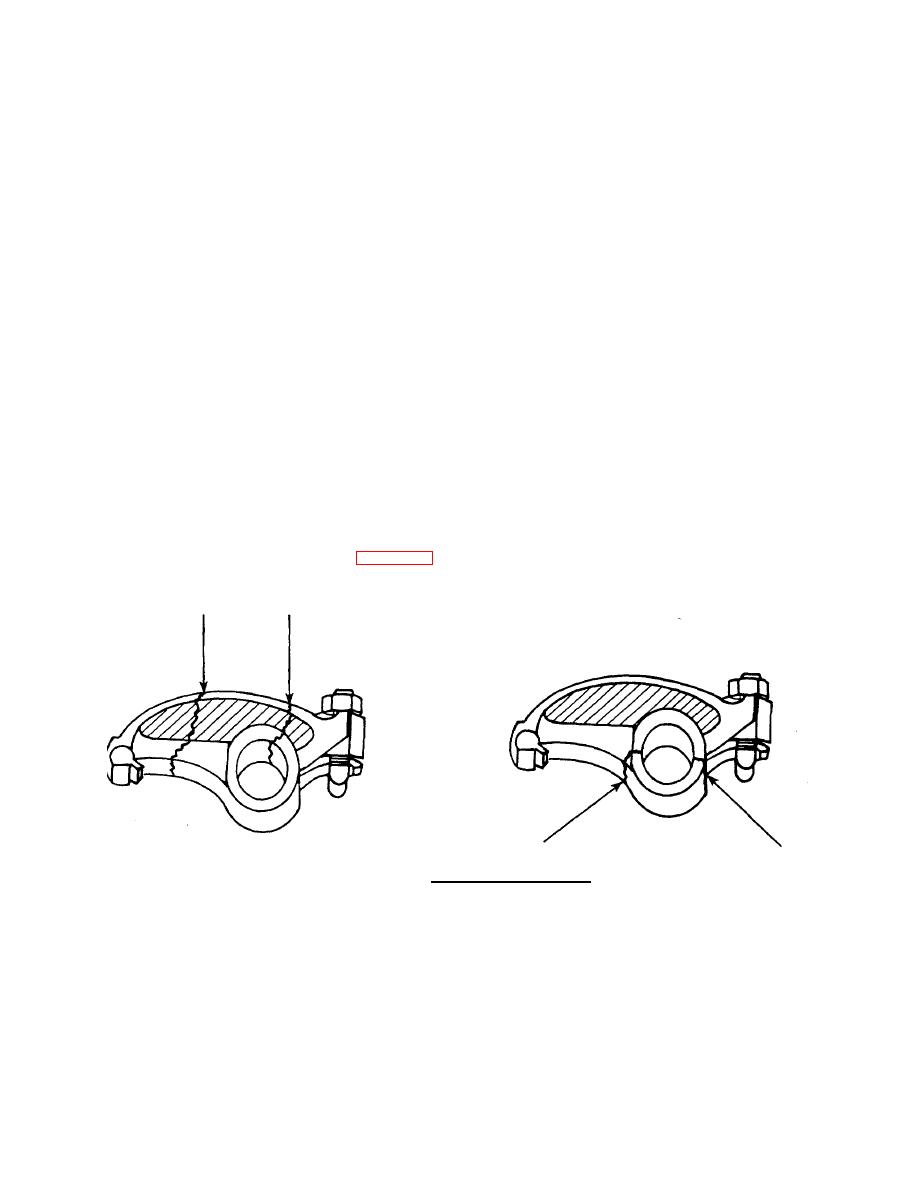

Use magnetic inspection to check the rocker arms and rocker levers for cracks. Use coil

magnetization with amperage at 300 to 500 with residual Magnaglo. Special attention should be given

to the areas indicated in Figure 3-21.

FIGURE 3-21. Crack Inspection Areas.

3-51

|

||

|

||