| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

(k) Install the cutter and pilot in a drill press.

(1) Cut the seat for the injector. Be sure to use enough oil while cutting the seat.

(m) The seat must have a smooth surface.

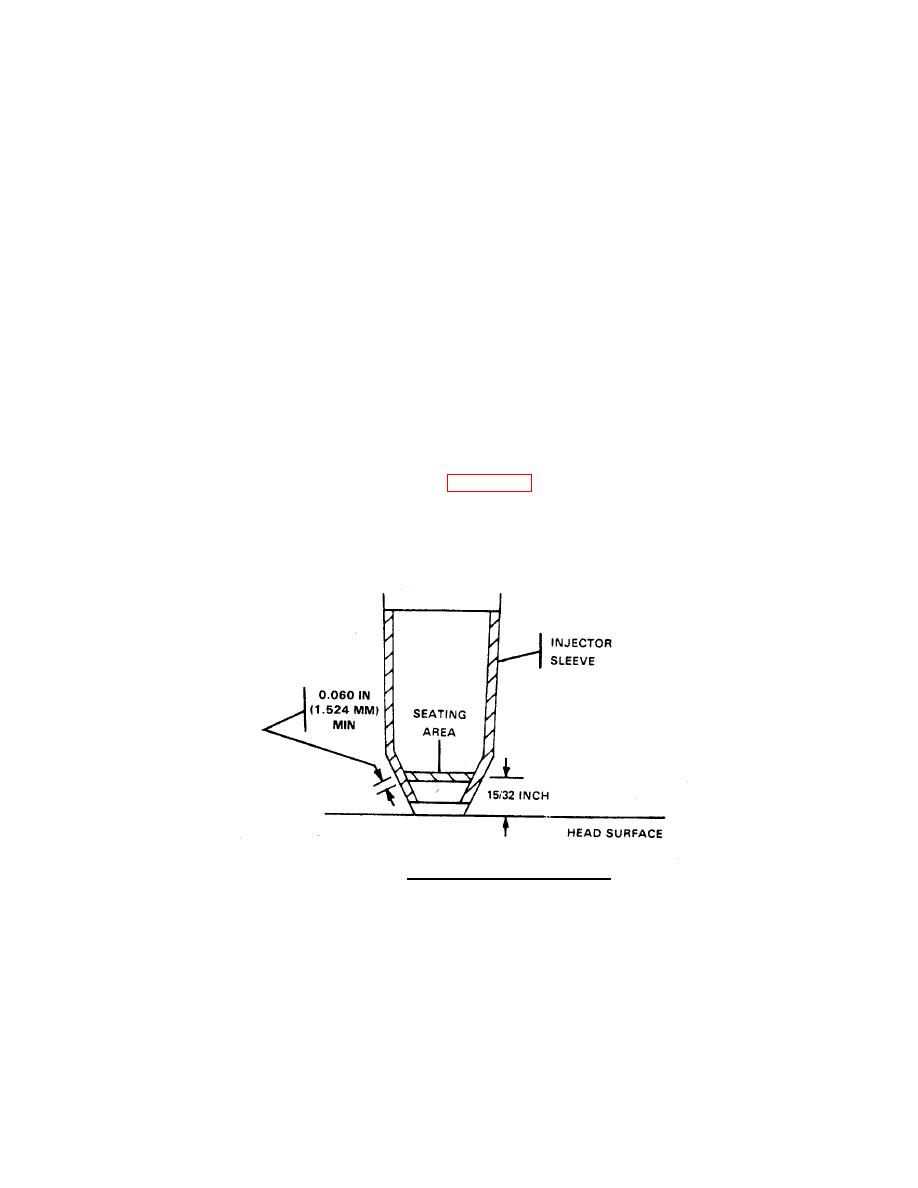

(n) Apply Prussian blue compound to the inside of the sleeve at the area of the injector seat. When the

injector is installed, the compound must show completely around the injector and must be a minimum

width of 0.060 inch (1.52 mm).

(3)

Check injector protrusion. Check the sleeve to ensure the protrusion of the injector tip and the seating

pattern is correct.

(a) Apply a light coat of blue compound to the injector cup.

(b) Install the injector assembly into the sleeve.

(c) Tighten the capscrews to 10 to 12 ft-lb (13 to 16 N m) torque.

(d) Remove the injector and check the pattern of the blue compound in the sleeve.

(e) The pattern in the sleeve must be a minimum of 0.060 inch (1.52 mm) wide and 0.469 inch (11.91 mm)

from the bottom surface of the cylinder head (Figure 4-17).

(f)

If the sleeve does not meet those specifications, it must be replaced.

FIGURE 4-17. Injector Sleeve Measurements.

4-47

|

||

|

||