| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

(3)

Visually inspect the bearings (11) for damage.

NOTE

Replace any bearings with lock tang damage or scratches

(deep enough to be felt with a fingernail). Also replace any

bearings which show pitting, flaking, or corrosion in the

copper lining.

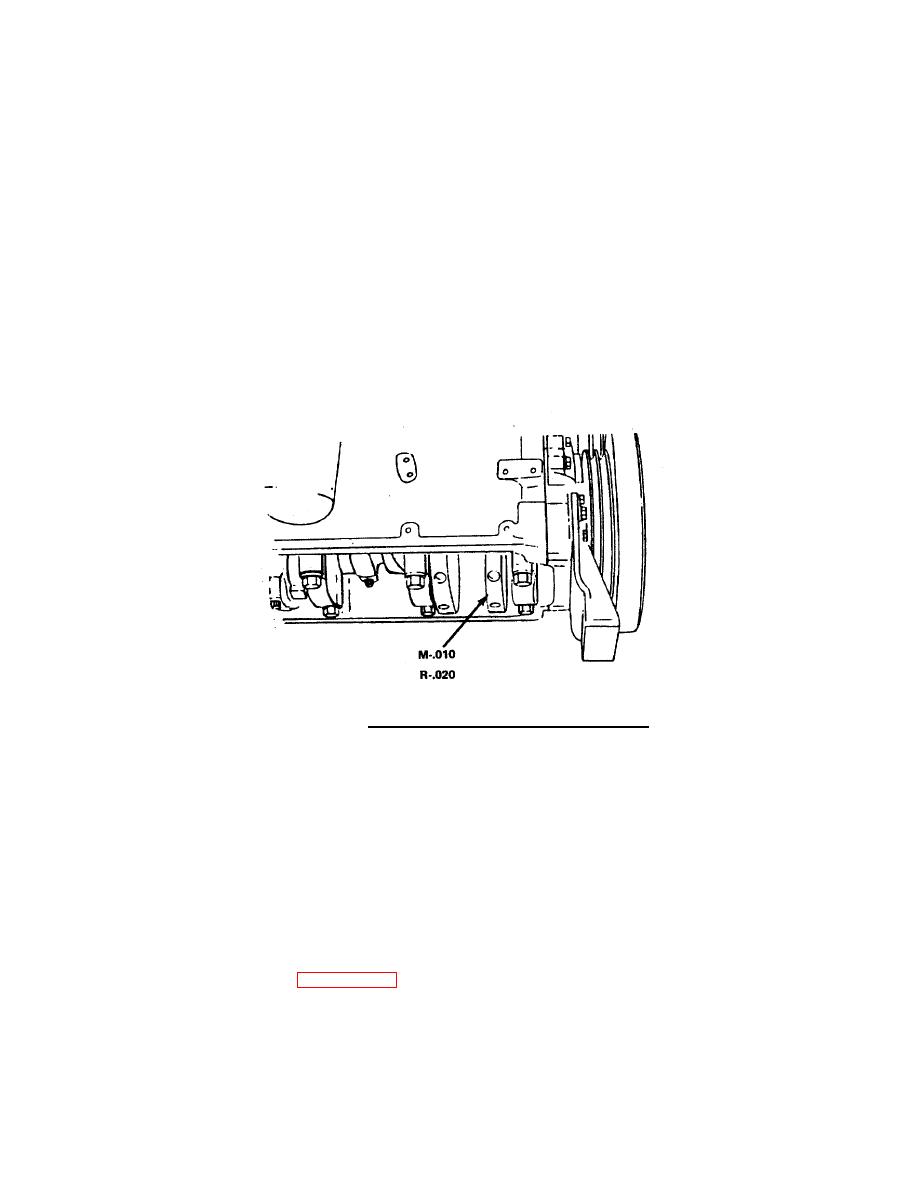

Bearing shells (12) are available for crankshafts which are

0.010 inch (0.25 mm), 0.020 inch (0.51 mm), 0.030 inch

(0.76 mm), or 0.040 inch (1.02 mm) undersize. Crankshafts

which are ground undersize in the connecting rod or the

main bearing journals are marked on the front counter

weight. If the crankshaft is marked, check the bearing shell

to make sure the correct bearing size is used (FIGURE 4-

33) .

FIGURE 4-33. Counterweight Markings for Bearing Sizes.

NOTE

Normal bearing wear produces a smooth finish which will wear

into the copper lining. Exposed copper does not always indicate

worn bearings. If large areas of copper lining are visible in the

bearings before the engine has accumulated 3,750 hours,

inspect the engine for contamination from fine dirt particles and

correct the problem.

(4)

Visually inspect the bearing seating surface for nicks or burrs.

(5)

If nicks or burrs cannot be removed with a fine crocus cloth, the

bearings (11, FIGURE 4-31) must be replaced.

(6)

Measure the rod bearing shell (11) thickness with an outside micrometer

that has a ball tip.

4-68

|

||

|

||