| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

(7)

The bearing thickness should be between 0.093 inches (2.362 mm) and 0.0947 inches (2.405

mm). Replace bearing shell (11) if it is not within these measurements.

b.

Clean and inspect the connecting rods (1).

(1)

Use steam or solvent to clean the connecting rods (1).

(2)

Use a nylon bristle brush to clean the oil drillings.

(3)

Dry with compressed air.

(4)

Replace the rod (1) if the "I-Beam" is nicked or damaged.

(5)

Inspect the rod pin bore bushing (2) for damage or misalignment of the

oil passage and the bushing.

(6)

Use the magnetic particle detection kit to find cracks in the connecting

rods (1) and machine bolts (10). Discard the part if cracks are found.

NOTE

Some joints in the forging will show as cracks. Make sure to

check the rod for the location of these joints. These lines are

not an indication of cracks. Do not discard parts with these

marks.

(7)

Inspect the connecting rod pin bushing bore and crankshaft bore.

(a)

Be sure to keep the connecting rod (1) and the cap together.

(b)

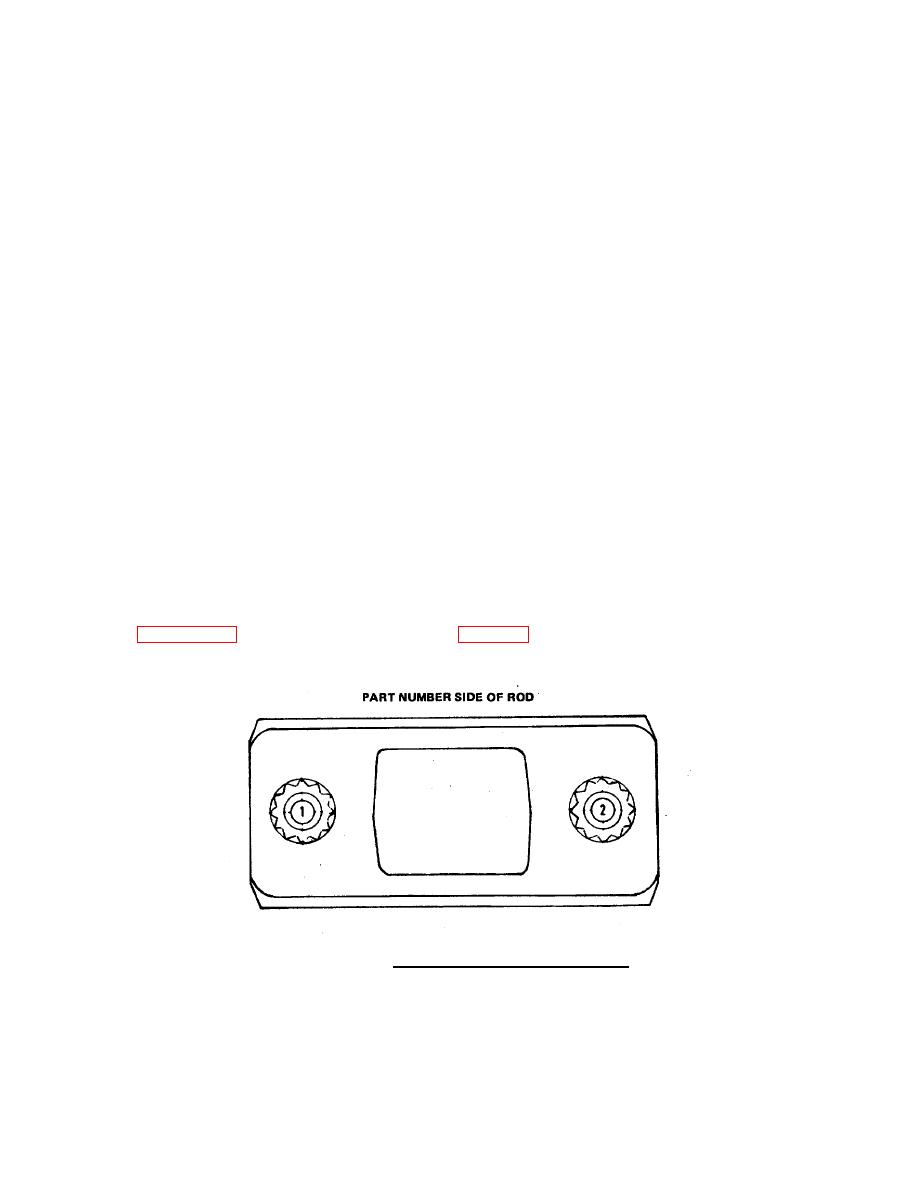

Assemble the rod (1) and tighten the machine bolts (10) to the correct torque in the correct sequence.

FIGURE 4-34. Connecting Rod Torque Sequence.

4-69

|

||

|

||