| Tweet |

Custom Search

|

|

|

||

TM 55-1905-242-14

0192 00

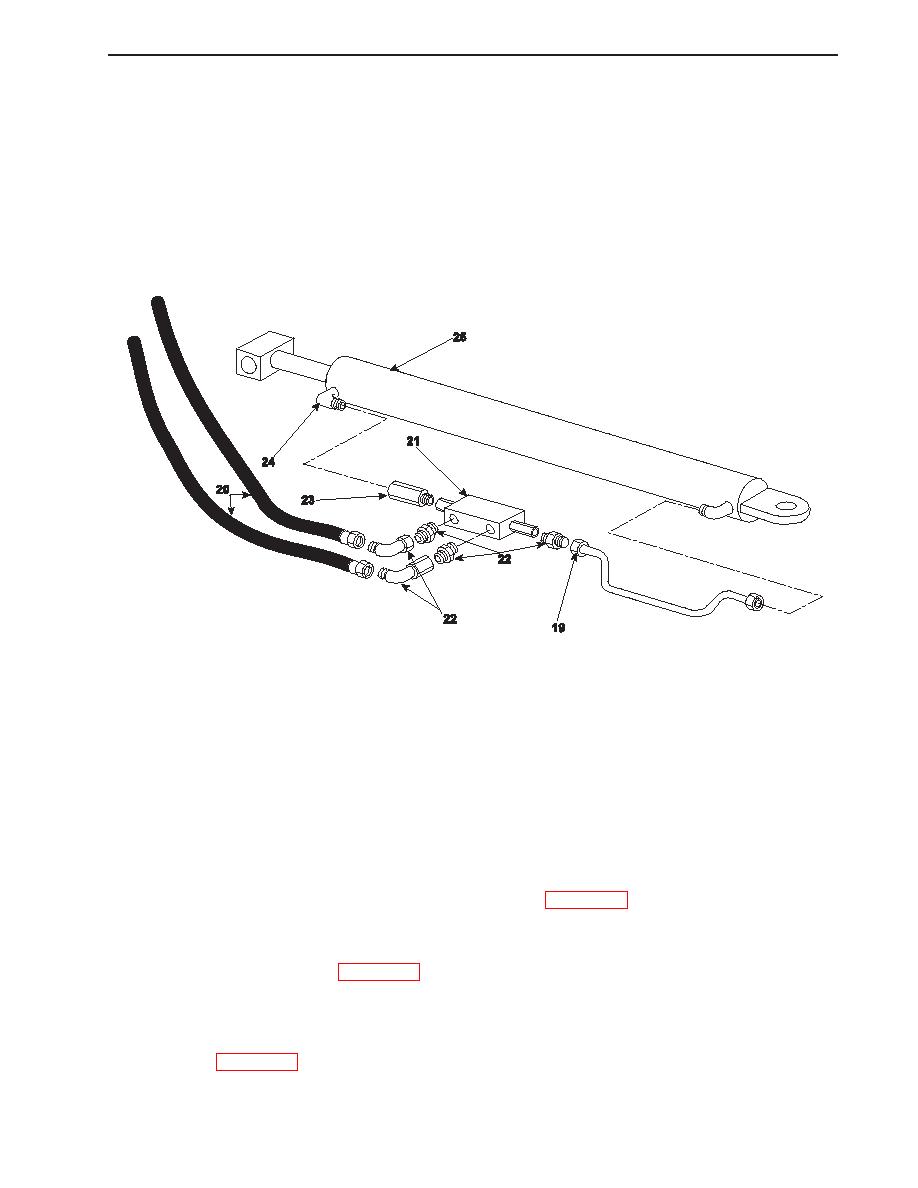

REMOVAL--EXTENSION CYLINDER HOLDING VALVE

1.

Don chemical protective gloves and goggles and position a suitable drain pan beneath the work area.

2.

Loosen, but do not remove, the piping (19) and hoses (20) at the holding valve (21) to permit any residual hydraulic fluid

or pressure to drain from the system.

3.

Label and remove the piping (19), hoses (20), and fittings (22).

4.

Unscrew the holding valve (21), fitting (23), and elbow (24) as a unit from the extension cylinder (25).

INSTALLATION--EXTENSION CYLINDER HOLDING VALVE

1.

Assemble the holding valve (21), fitting (23), and elbow (24) and install them as a unit into the extension cylinder (25).

2.

Install the piping (19), hoses (20), and fittings (22) using the labels from step 3 of Removal--Extension Cylinder Holding

Valve as a guide.

3.

If no further work will be performed, remove the lockouts and tagouts and check the operation of the system, ensuring

that the boom cylinder moves smoothly in both directions and that it does not "drift" when the control lever is released.

4.

Dispose of used hydraulic fluid and contaminated materials in accordance with local regulations.

5.

Notify general support maintenance to perform a lift test on the crane (WP 0222 00)

REPAIR--VALVE BANK

Repair of the valve bank is described in WP 0158 00.

REPAIR--HOSES AND FITTINGS

Repair of the hoses and fitting is accomplished by the replacement of the defective hoses and/or fittings. For replacement

procedures refer to WP 0157 00.

END OF WORK PACKAGE

01920192 00-5

00-5/6 blank

|

||

|

||