| Tweet |

Custom Search

|

|

|

||

TM 55-1905-242-14

GENERAL SUPPORT MAINTENANCE

FOR LANDING CRAFT, MECHANIZED (LCM-8) (ALL VESSELS WITH MOD 2 APPLICATION)

PROPELLER SHAFT, ALIGN

INITIAL SETUP:

Tools and Special Tools:

Personnel Required:

Tool Kit, Mechanic's Rail and Marine (Item 1,

Two Watercraft Engineers, 88L

Table 1, WP 0230 00)

References:

Dial Indicator (Item 5, Table 1, WP 0230 00)

FM 55-502

Equipment Condition:

Propulsion engines secured, locked out, and

tagged out IAW FM 55-502

Vessel afloat for final alignment

ALIGNMENT

NOTE

Propeller shaft alignment is not permanently fixed. The alignment changes with every

docking due to changes in the keel blocking, temperature variations, and the direction of

the sun's rays relative to the fore and aft line of the vessel. The alignment of shafting is

affected by the temporary removal of machinery attached to the shafting or in the

vicinity of the shafting because of the redistribution of weights and stresses. The

alignment is not the same when the vessel is waterborne as when it is in drydock. The

final alignment and bolting of the main propulsion shafting should always be done

when the vessel is waterborne.

1.

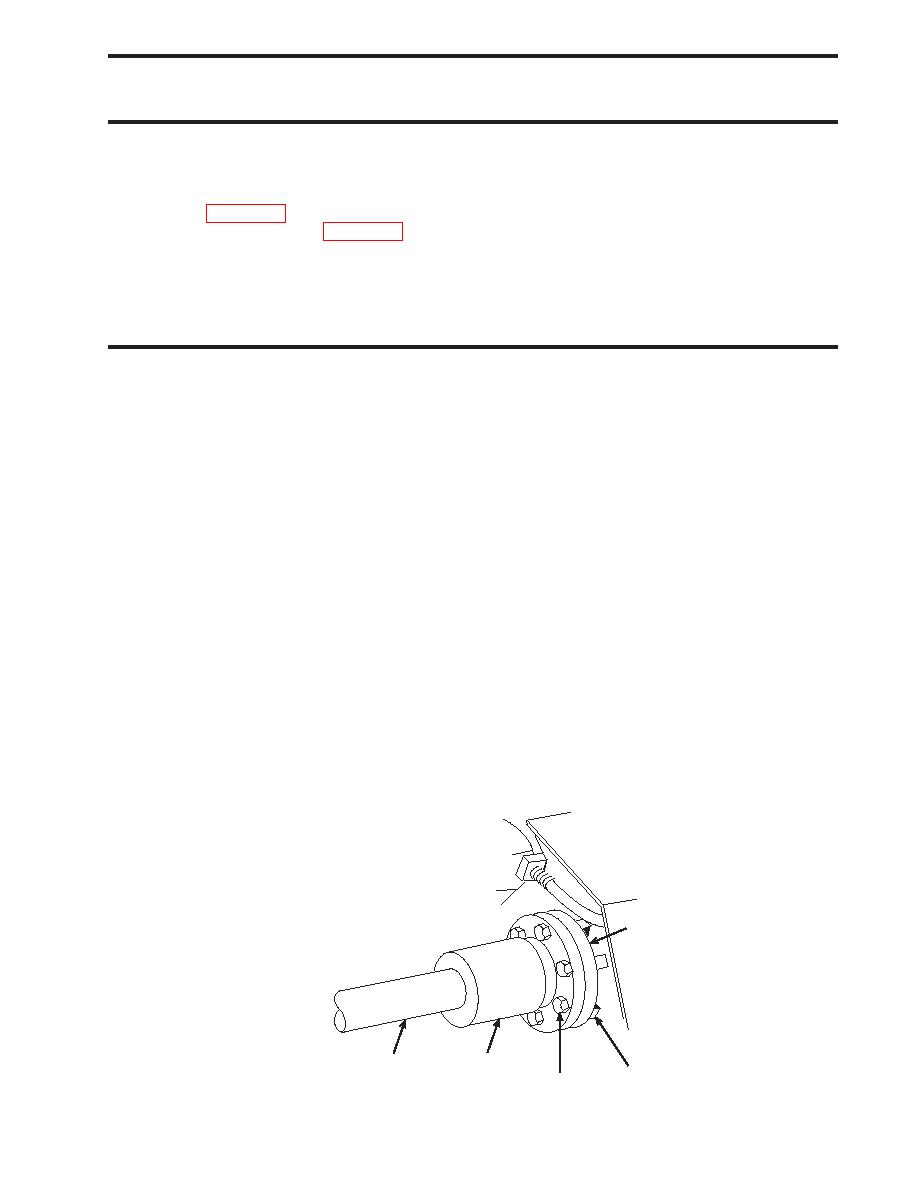

Remove the bolts (1) and nuts (2) that secure the shaft coupling (3) to the transmission output flange (4).

2.

Slide the propeller shaft (5) back to allow clearance between the shaft coupling (3) and the transmission output

flange (4).

3.

Clean the mating faces of the shaft coupling (3) and the transmission output flange (4) with a wire brush, ensuring that

both surfaces are clean, smooth, and free of corrosion.

4.

Fasten the dial indicator fixing stand (6) to the shaft coupling (3) as shown to check the angular alignment.

4

3

5

2

1

0202 00-1

|

||

|

||