| Tweet |

Custom Search

|

|

|

||

TB 55-1900-201-45/1

test or by a test with electronic or ultrasonic devices or other non-destructive testing (NDT).

c. For certification, testing of the assembled units under proof loads, followed by a disassembly of such gear for a

thorough examination shall be made once every four (4) years, or more often if necessary. The "disassembly" of units of

gears is necessary to determine the suitability of such gear for continued service.

d. Quadrennial inspections and certification of cargo gear shall be performed by one of the following approved

certifying organizations:

(1)

National Cargo Bureau

(2)

International Cargo Gear Bureau

(3)

Universal Cargo Gear Survey and Certification Bureau

2-35. Factors of Safety. In the testing of the cargo gear, the safety factors in Table 2-2, shall be used and regarded as

minimum.

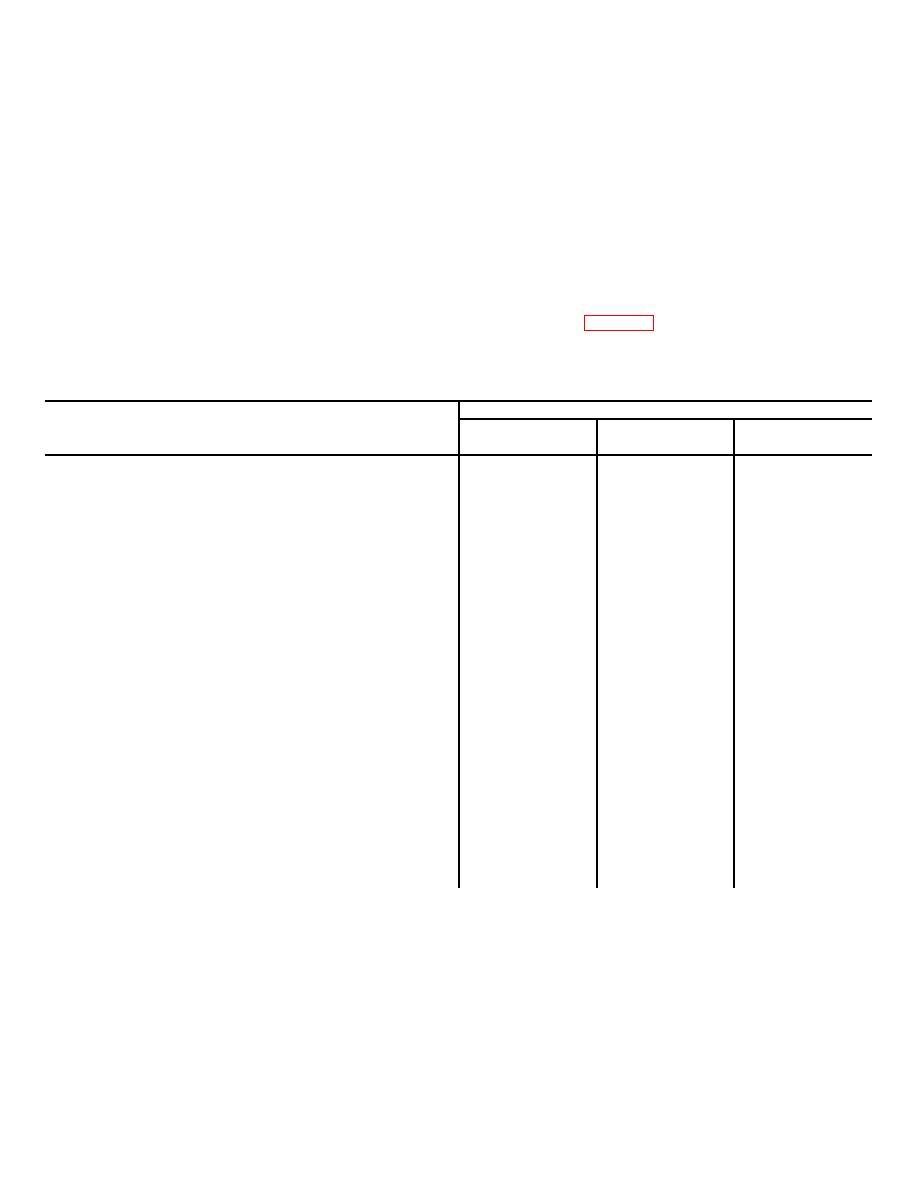

Table 2-2. Safe Working Loads for Component Parts

COMPONENT PARTS

SAFETY FACTORS BASED ON

ULTIMATE

YIELD

BREAKING

STRENGTH

POINT

TEST LOAD

All metal structural parts, except steel booms:

When the working load of the assembled gear is 10 tons*

` **

5

or less

When the working load of the assembled gear is 13 tons or

`

4

over

Steel booms:

When the working load of the assembled gear is 10 tons or

`

3

less

When the working load of the assembled gear is 13 tons or

over

` 1/2

2

Wooden structural parts

'8

Chains

4

Wire Rope:

For working loads 10 tons or under

5

For working loads over 10 tons4

4

Fiber rope:

When intended for running rigging

7

When intended for fixed gear & vangs

5

2-21

|

||

|

||