| Tweet |

Custom Search

|

|

|

||

TB 55-1900-201-45/1

(2) The existing plate should be cut back to good material. (No less than 3/4 thickness of plate being inserted.)

The existing plate edge and the internals in way of the cutout should always be examined before the insert is installed.

(3) The shipfitting and plate edge preparation should be such that welding grooves of proper proportions are

provided so that acceptable welds can be made.

(4) The weld metal of intermediate passes on butts and seams of restrained insert plates may be peened. The

finish pass should not be peened but may advantageously be made using low hydrogen electrodes.

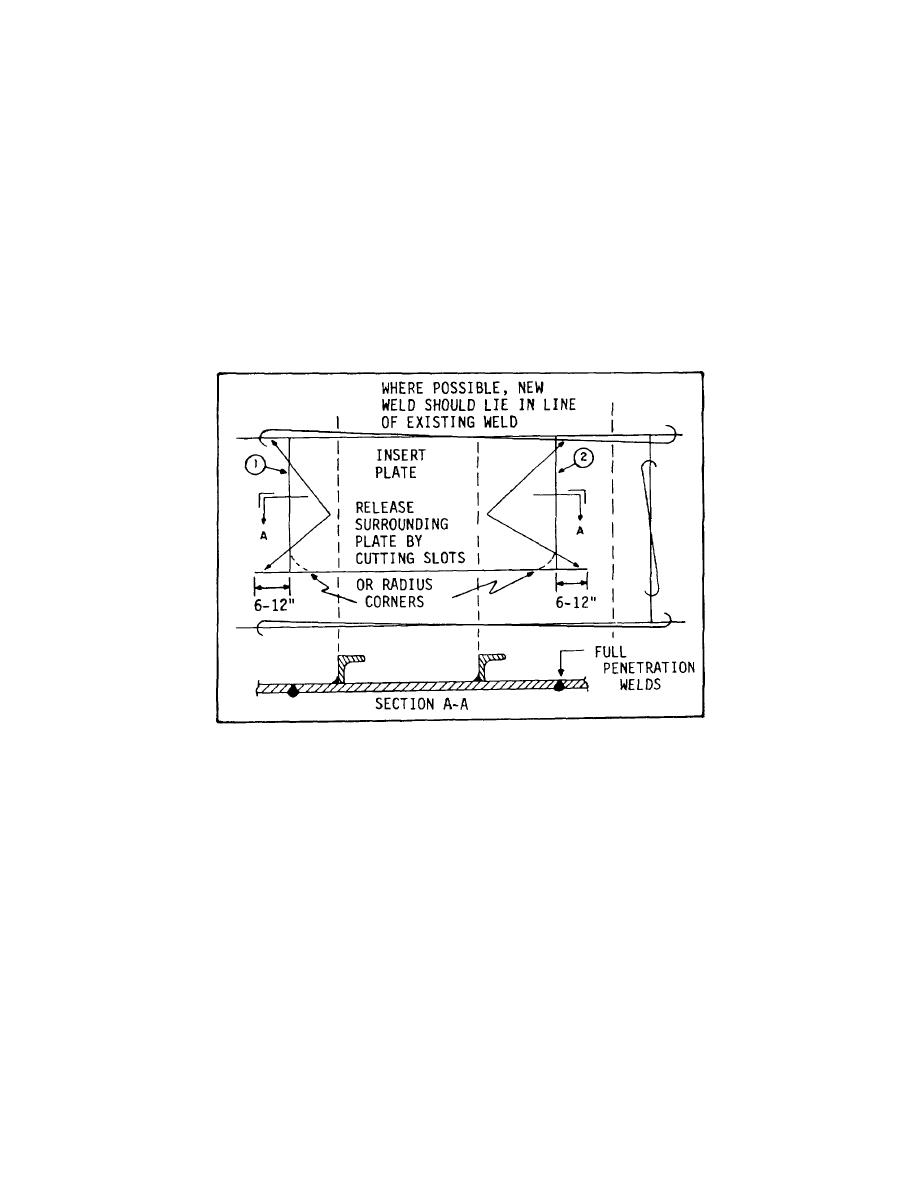

(5) To minimize locked-in stresses when installing an insert plate, it is necessary to ease the restraint imposed

by the surrounding structure. First, holes should be drilled as shown below to reduce the likelihood of cracks occurring at

the ends of the slots. The adjacent plating should then be slotted as shown below. Butts 1 and 2 can be welded first so

that the slots can serve to distribute the shrinkage somewhat rather than concentrating it at the immediate boundaries of

the insert plate. Rounding the corners of the insert plate, not in way of existing seams or butts, is an acceptable alterna-

tive.

Method of Installing an Insert Plate

(6) In certain cases, a welded lapped patch plate may be used in lieu of an insert plate for the permanent repair

of small damaged areas which lie wholly within an individual panel of plate. However, except for temporary repairs, their

use should not be permitted in the strength deck, bottom or shell plating. Patch plates are also inadvisable in areas of

high corrosion. In making the installation, the old plate should be cut away to a sufficient thickness of sound metal so

that the existing metal at the edge of the

E-17

|

||

|

||