| Tweet |

Custom Search

|

|

|

||

TB 55-1900-232-10

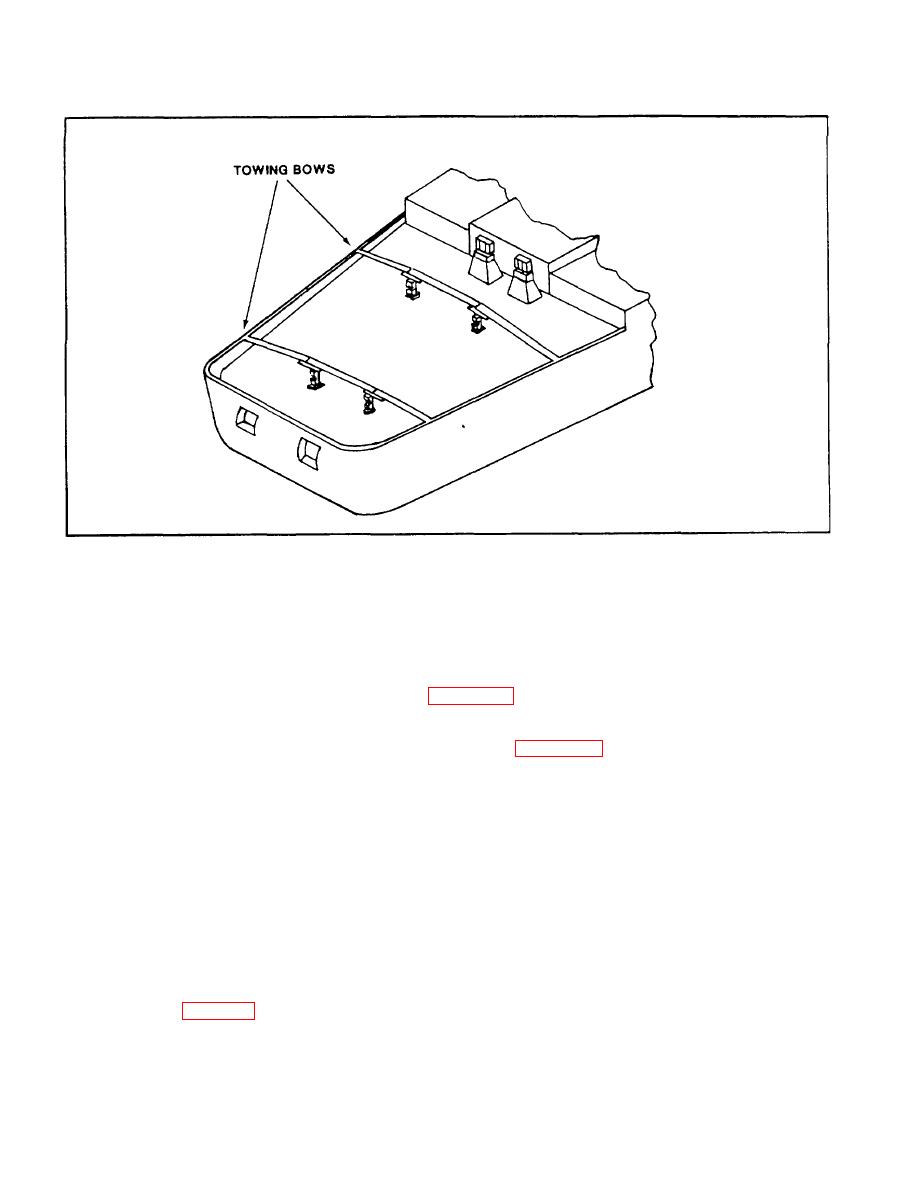

FIGURE 2.33. Towing Bows

in fixed locations, unlike some of the older ships whose round pins physically could be lifted out of any socket and either

removed or moved to another location. This necessitated personnel moving about on the fantail and thus being subject

to hazards, with remote control, the procedures are now safer. On board the ARS 50 Class, the Norman Pins, like the

vertical stern rollers, are set to drop when the lateral force at mid-barrel height exceeds 50,000 pounds. The hazard

potential could be formidable, since when the pins start inclining toward the horizontal, the wire with 25 tons force

propelling it could jump the pin and sweep forward. See Figure 2-39.

2-5.10 3 Bulwark Forward Limits. On most Navy towing and salvage vessels the bulwark and the caprail are gently

curved upward and faired into the deck above the towing deck. See Figure 2-40. This ship's structure restricts the tow

wire from leading forward of the beam at the tug's tow point (H-bitts) just aft of the tow winch.

2-5.10.4 Lateral Control Wire. The lateral control wire is a wire or tackle rigged to control the athwart- ships movement

of the towline. A dedicated lateral control winch is available on the ARS 50 Class ships. By changing the scope of the

lateral control wire, the bight of the towline can be moved to different locations on the fantail. The lateral control wire

also is employed to keep the towline out of the screws during slack wire conditions. The lateral control winches are

limited to approximately 2,000 pounds straight line pull.

SECTION VI

2-6 TOWLINE COMPONENT MATERIALS

Some materials used in tensile members of towing systems are characterized by high levels of elasticity

(Text continued on page 2-50)

2-45

|

||

|

||