| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

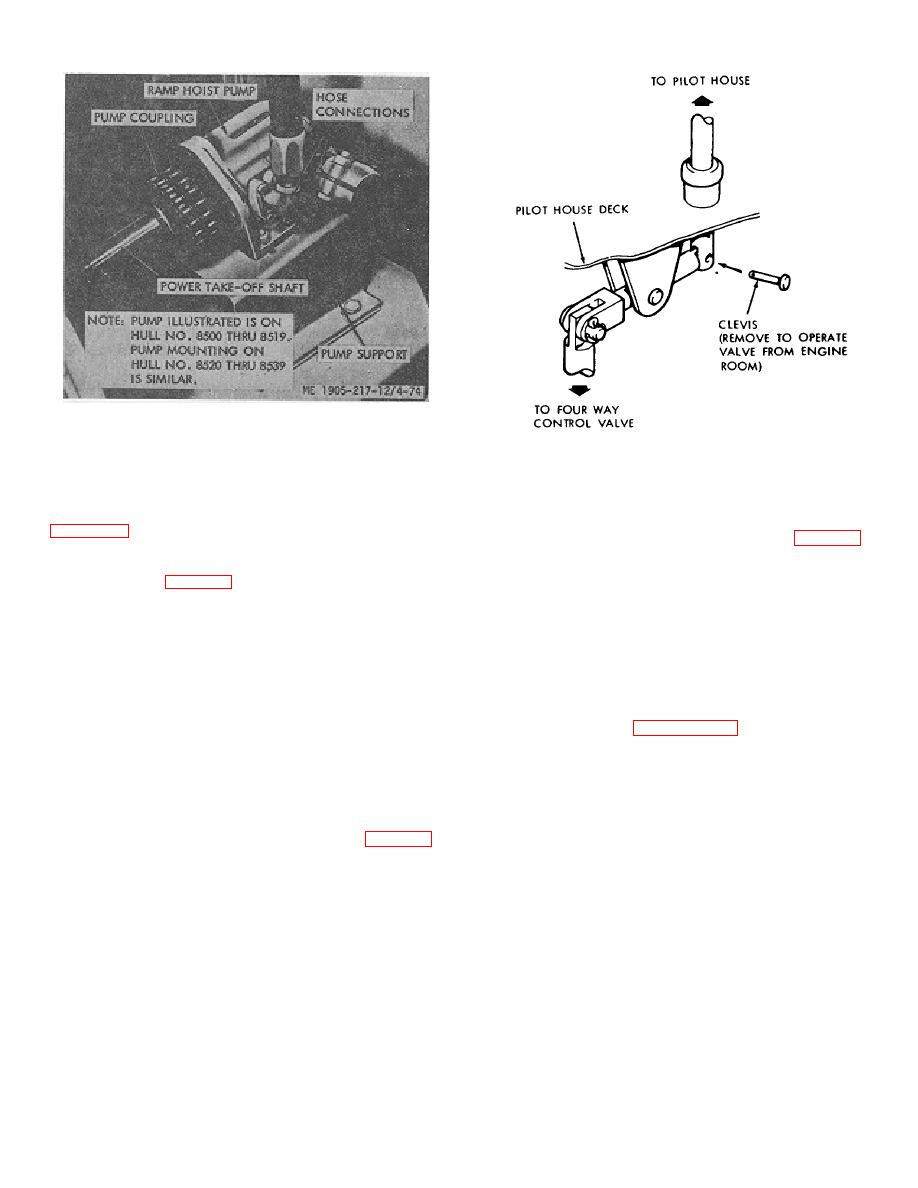

Figure 4-74. Ramp hoist hydraulic pump.

R20BL valve mounted just below the deck in the engine

ME 1905-217-12/4-75

room. The control lever is on the starboard side of the

Figure 4-75. Ramp hoist control valve linkage

pilot house. The control valve used on hull numbers 8540

installation, hull numbers 8540 thru 8560 and 8580 thru

thru 8560 and 8580 thru 8618 incorporates an internal

8618.

relief valve which limits system pressure to 2100 psi. See

4-91. Winch (Hull Numbers 8520 thru 8539 (fig. 4-78))

hull numbers 8540 thru 8560 and 8580 thru 8618.

The winch is located forward on the starboard aside of

the hull. Maximum line pull is 22,000 pounds at 1,900 psi.

b. Removal (fig. 4-76).

The winch consists of a primary drive housing and a final

drive housing fastened to a winch base 'by dowel bolts

(1) Clean hose connections, disconnect, and

which hold the housings concentric. The primary drive

cap open ends. Tag hoses to assure proper

housing contains a hydraulic motor which drives the sun

reconnection.

gear of a primary planetary reduction.

(2) Disconnect operating lever link

(,hull

4-92. Ramp Hoist Pump (Hull Numbers 6520 thru

numbers 8520 thru 8560 and 8580 thru 8618).

8539)

a. General. See figure 2-26.1. The hand pump is

(3)

Remove mounting bolts and remove control

used only for emergency lowering of the ramp. Pressure

valve.

provided by the hand pump will release the winch brake

as controlled by the ball valve

c. Installation. Install control valve in reverse order

of removal.

b. Service. Oil level in the hand pump reservoir

should be approximately 2/8 full.

4-90. Winch (Hull Numbers 8500 thru 8519 (fig. 4-77)

The winch is mounted forward in the port side of the hull.

c.

Removal.

It is rated at 200 psi operating pressure, with a line pull of

14,2.50 pounds and a line speed of 100 feet per minute

(1)

Clean pipe fitting and disconnect oil line.

at the first cable layer (bare drum). Hoist or lower time is

approximately 11 seconds. The winch -is driven by a

(2)

Remove mounting nuts and remove hand

hydraulic motor through a double reduction gear reducer.

pump.

Cable is underwound on the winch.

d. Installation. Install hand pump in reverse order of

removal.

4-76

|

||

|

||