| Tweet |

Custom Search

|

|

|

||

TM 55-1905-219-14-5

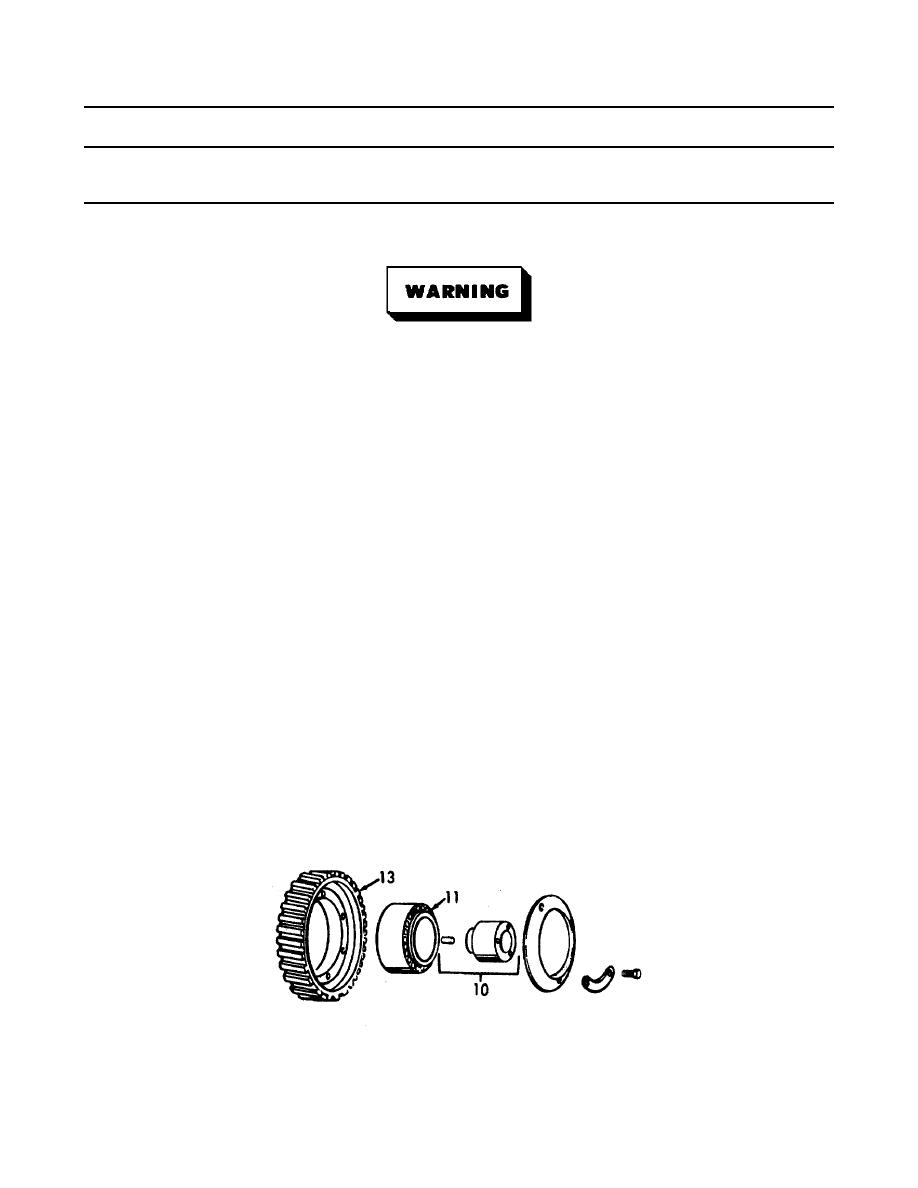

3-91.3. IDLER GEAR AND BEARING ASSEMBLY - MAINTENANCE

INSTRUCTIONS (Cont).

LOCATION

ITEM

ACTION

REMARKS

INSPECTION

Wear eye protection when using compressed air.

3.

a. Idler

1. Wash in clean fuel oil

gear

and dry with compressed

(13),

air.

hub (10)

and bear-

2. Inspect all parts for

ing (11)

wear.

b. Bearing

Inspect bearings carefully.

(11)

Wear, pitting, scoring or

flat spots on rollers or

races are sufficient cause

for rejection and the

bearing assembly must be

replaced.

c. Hub (10)

Check the idler gear hub

and spacer.

d. Idler

Examine the gear teeth

gear

for evidence of scoring,

(13)

pitting and wear. If

severely damaged or worn,

replace the gear. Also,

inspect other gears in

the gear trains.

3-1576

|

||

|

||