| Tweet |

Custom Search

|

|

|

||

TM 55-1905-220-14-5

3-91.3. IDLER GEAR AND BEARING ASSEMBLY - MAINTENANCE

INSTRUCTIONS (Cont).

LOCATION

ITEM

ACTION

REMARKS

PRE-LOAD CHECK OF BEARING (Cont)

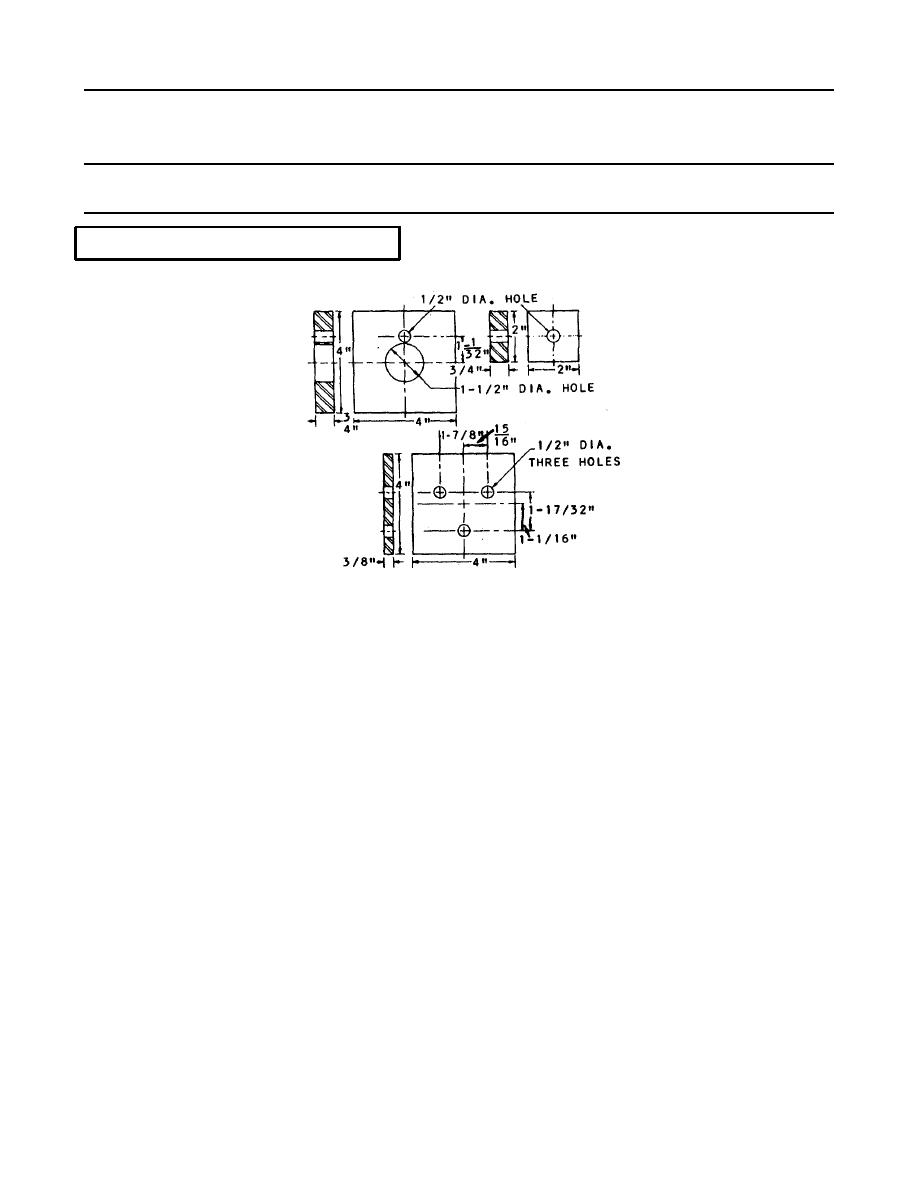

(3) Place steel plate (lower plate) against hub and bearing. Insert three 3/8"-16 bolts through plate and

threaded into hub. Tighten the bolts to 25-40 lb-ft torque.

(4) Tie one end of a piece of lintless 1/8" cord around a 1/8" round piece of wood (or soft metal stock).

Place the wood between the teeth of gear, then wrap the cord around the periphery of the gear

several times. Attach the other end of the cord to spring scale. Maintain a

scale, 90to the axis of the hub, and note the pull, in

straight, steady pull on the

pounds and ounces, required to start the gear

rotating. Make several checks to obtain an average

reading. If the pull is within 1 1/4 lb. minimum to

6 lbs. 12 ounces maximum and does not fluctuate

more than 2 lbs. 11 ounces, the idler gear and

bearing assembly are satisfactory for use.

i.

To check the pre-load by the second method:

(1) Attach the plates (two upper plates) to the idler gear with 1/2"-13 center bolt, washers and nut as

shown. Tighten the bolt to 80-90 lb-ft (119-134 kg/m) torque.

3-1563

|

||

|

||