| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-10

REPAIR RAMP WINCH (Continued).

1. Repeat the above steps, from step b, for all

three primary planet gears (48) and, when they

are installed, check that all the gears rotate

freely in the correct direction.

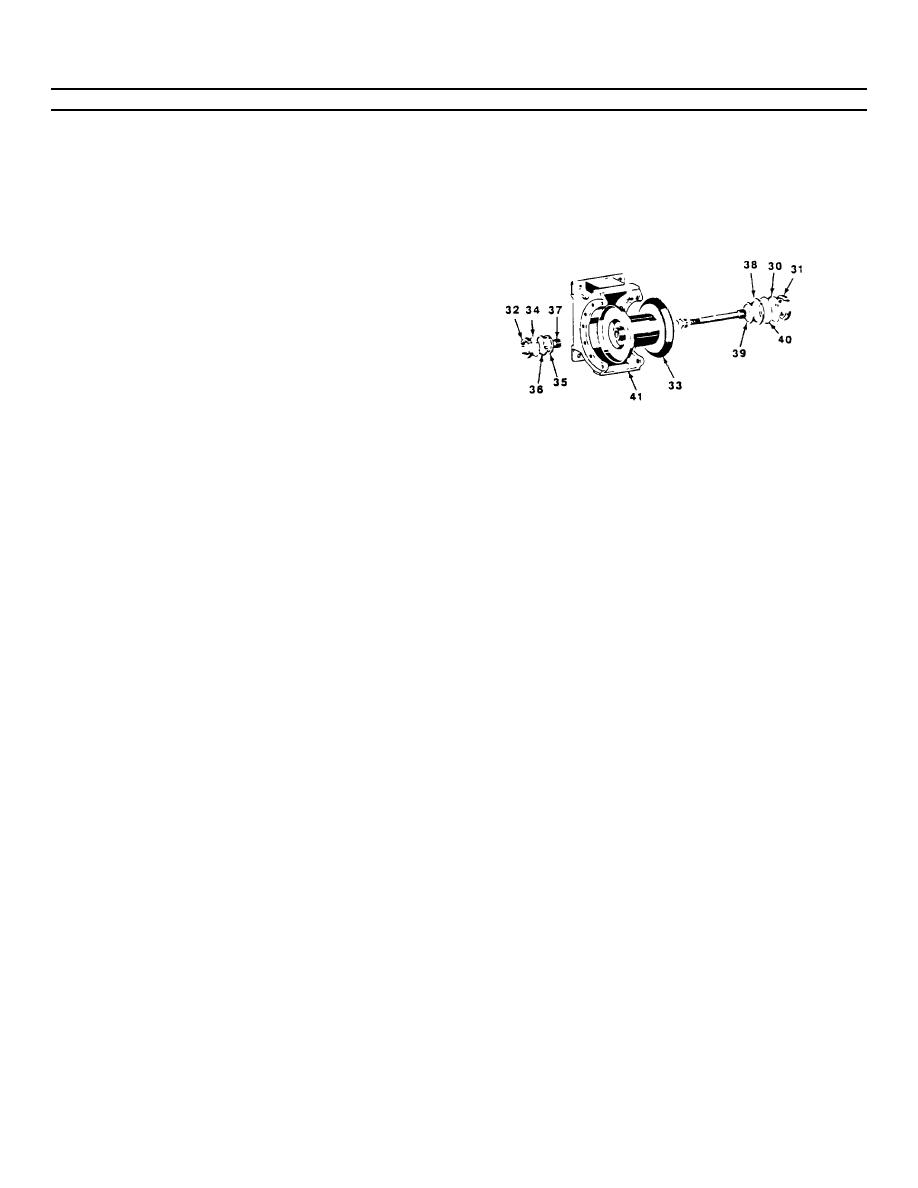

3. ASSEMBLE BEARINGS AND SEALS IN DRUM.

a. Install oil seal (35) in small seal ring (34) so

that the lip of the oil seal is at the end of the

seal ring farthest from the 'O' ring groove.

b. Lubricate 'O' ring (36) with grease and instal it

in the groove on the outside diameter of the seal

ring (34).

c. Lubricate the oil seal (35), give the 'O' ring an

additional coat of grease, and carefully install

this assembly on the non-splined end of the

drum (33). The lip of the oil seal should be

towards the drum. Pack the seal with grease

around the seal diameter of the drum.

d. Install oil seal (39) in large seal ring (38) so

that the lip of the seal is at the end of the seal

ring which has the projecting diameter at the

bore.

e. Lubricate 'O' ring (40) with grease and install it

in the groove on the outside of the seal ring.

f.

Lubricate the oil seal (39), give the 'O' ring (40)

an additional coat of grease and carefully

install this assembly on the splined end of the

drum (33). Pack the seal with grease around

the seal diameter of the drum.

6-54

|

||

|

||