| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

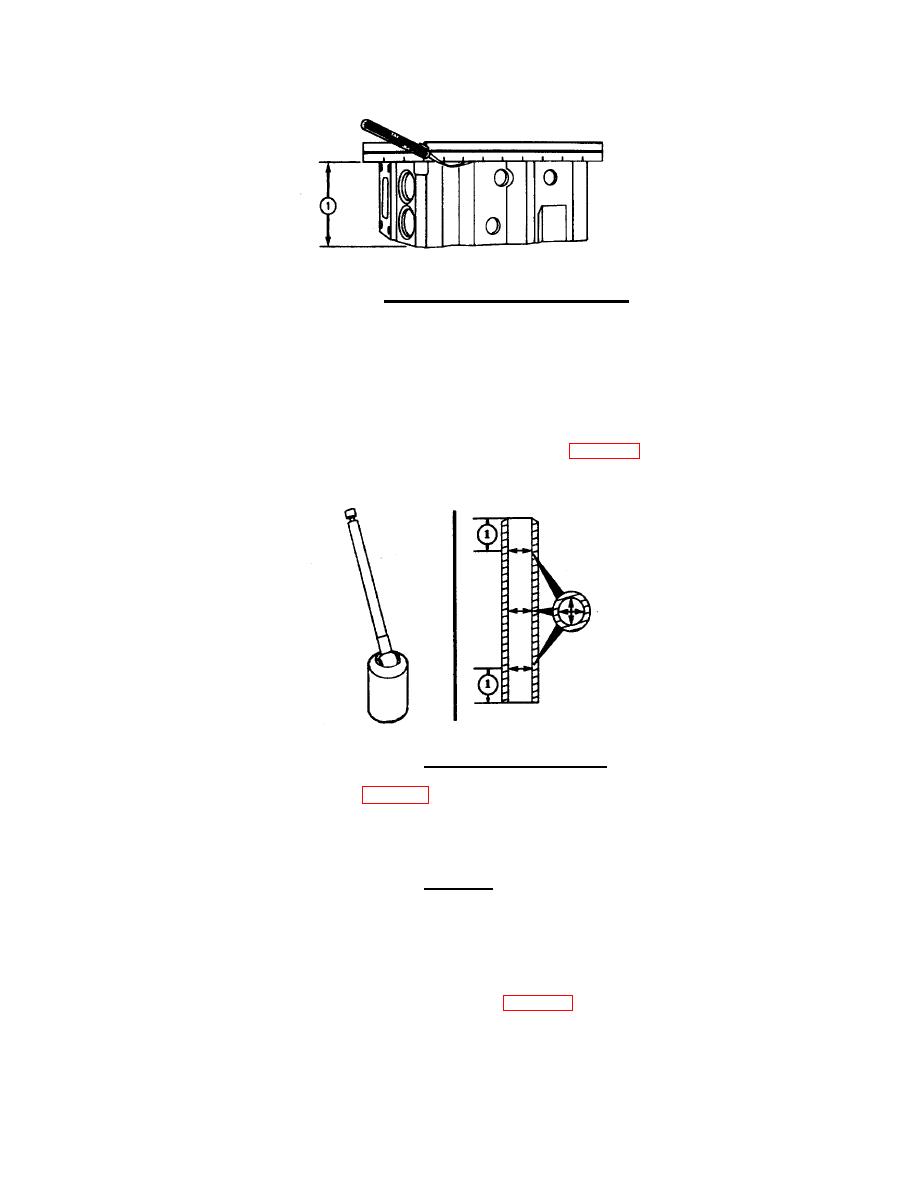

FIGURE 4-9.

Head Gasket Surface Measurement.

NOTE

The valve guide can be used again if measurements performed

near the top and bottom are greater than 0.4987 inch (12.667

mm).

(18)

Use a ball gauge or dial bore indicator. Measure the inside diameter of the valve guides 0.5

inch (13 mm) from the top and bottom and in the center (FIG. 4-10). Verify inside

diameter is between 0.4961 inch (12.601 mm) and 0.4987 inch (12.667 mm).

FIGURE 4-10.

Valve Guide Measurement.

(19) Verify crosshead guide (6, FIG. 4-3) is straight. Use micrometer to verify outside

diameter is between 0.4320 inch (10.973 mm) and 0.4335 inch (11.011 mm).

(20)

Magnetic crack check valves.

CAUTION

Always demagnetize and clean parts thoroughly after a

magnetic particle inspection. The iron fragments can damage

the internal engine components. A demagnetizing coil is

supplied with the magnaglo tester.

(a) Use magnaglo tester to check the valves (8, FIG. 4-3) for cracks. Check the exhaust

valves with the coil shot method. Check the intake valves with the coil shot and head shot

methods (coil shot first).

4-13

|

||

|

||