| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-2

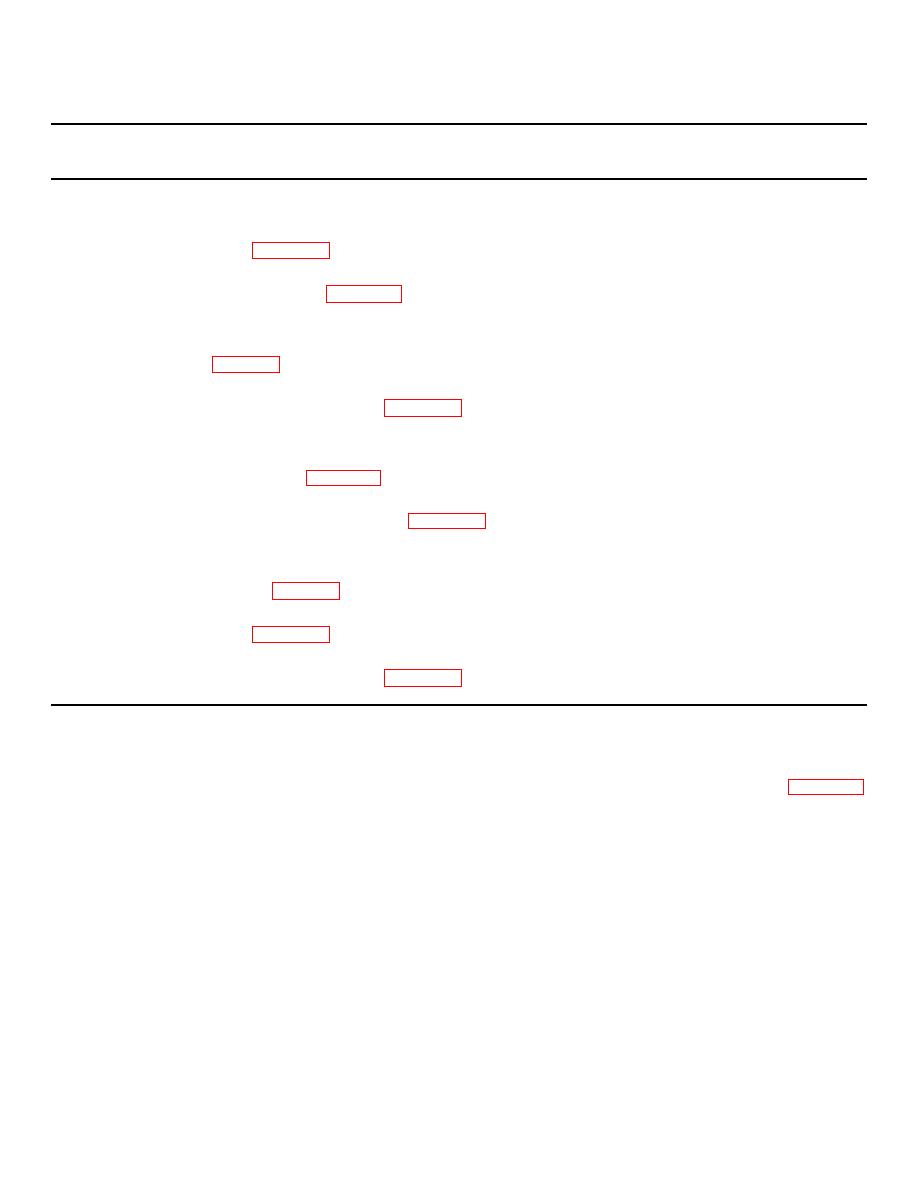

Table 3-1. Intermediate Direct Support Troubleshooting

Malfunction

Test or Inspection

Corrective Action

1. Gearbox oil temperature exceeds 2120F (normal range is 175-195 )

F

STEP 1. Check to see if pressure limiting valve is defective or blocked.

Replace distributor (para. 3-12).

Replace anti-friction bearings (para. 3-12).

2. Operating pressure too low or keeps changing (normal range is 260-280 psi).

STEP 1. Check to see if control valve is defective.

Repair valve (para. 3-9).

STEP 2. Check to see if pump drive or pump is damaged.

Repair or replace pump drive or pump (para. 3-12).

3. Using/losing oil.

STEP 1. Check shaft oil line connections.

Check and secure oil lines (para. 3-11).

STEP 2. Check to see if pump drive or pump is damaged from normal wear.

Replace pump drive or pump if necessary (para. 3-12).

4. Clutch is slipping or not engaging.

STEP 1. Check to see if control valve is defective.

Replace control valve (para. 3-9).

STEP 2. Check to see if non-return valve is defective.

Replace distributor (para. 3-12).

STEP 3. Pump drive or pump is damaged.

Repair or replace pump drive or pump (para. 3-12).

Section V. INTERMEDIATE DIRECT SUPPORT MAINTENANCE PROCEDURES

3-7. General. Direct support includes all actions authorized under unit maintenance plus internal repairs, within the

casings, authorized in this chapter. To understand the principles of the main reduction gear operation, read section III in

chapter 1.

3-3

|

||

|

||