| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

SECTION III. PRINCIPLES OF OPERATION

Overview. The principles of operation section will give you overall descriptions of

how the ship's service diesel generator set works. Keep in mind that proper engine

operation depends on two things: (1) compression for ignition, and (2) that fuel can

be measured and injected into cylinders in the proper quantity at the proper time.

1-13. Diesel Engine Operation. Diesel engines are different from spark-ignited engines in a number of ways.

Compression ratios are higher and the charge taken into combustion chambers during the intake stroke

consists of air only, with no fuel mixture. Injectors receive low pressure fuel from the fuel pump and deliver it

into individual combustion chambers at the proper time, in equal quantity, and in an atomized condition for

burning. Ignition of fuel is caused by heat of compressed air in the combustion chamber.

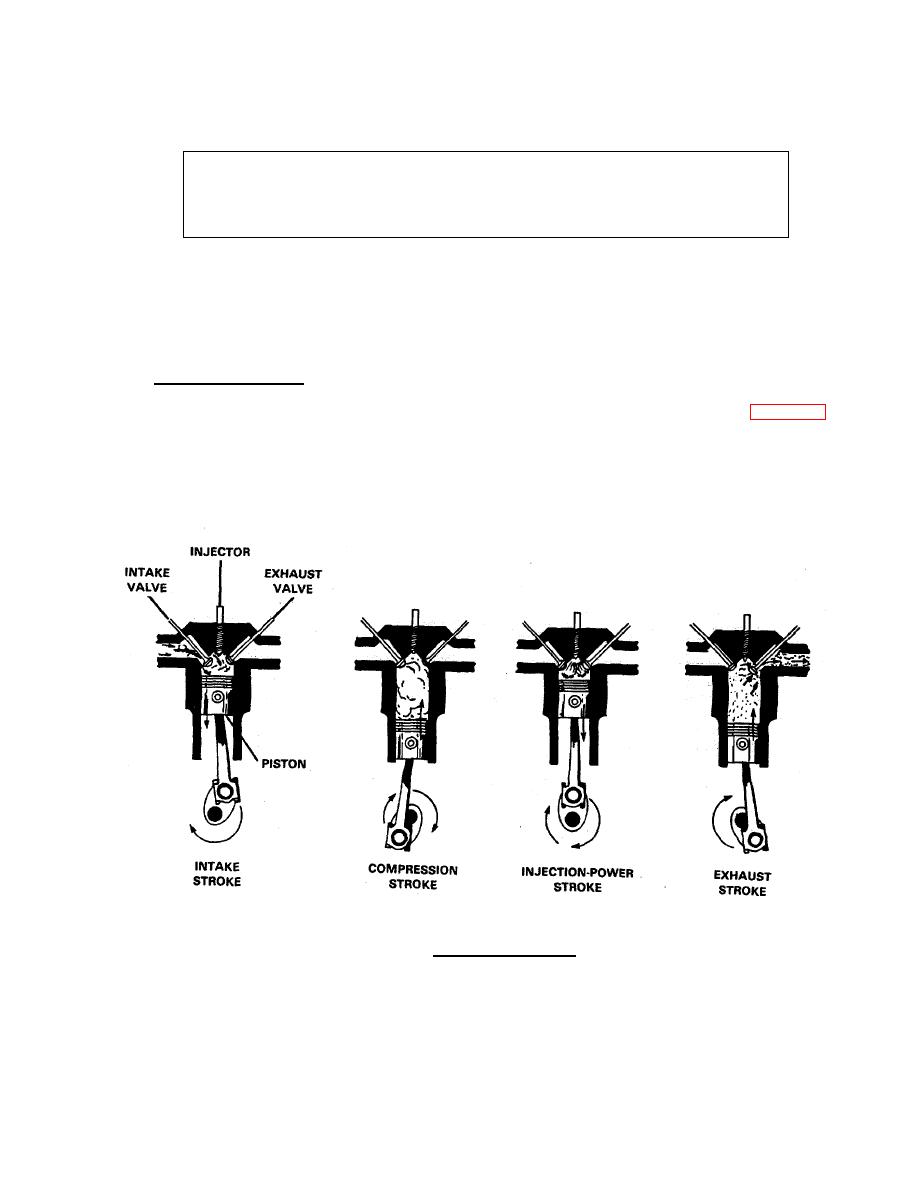

a. Diesel Engine Cycles. It is easier to understand the function of engine parts if you know what

happens in the combustion chamber during each of the four piston strokes of the cycle. The four strokes and

order in which they occur are: intake stroke, compression stroke, power stroke, and exhaust stroke (Figure 1-6).

In order for the four strokes to function properly, valves and injectors must act in direct relation to each of the

four strokes of the piston. The intake valves, exhaust valves, and injectors are camshaft actuated, linked by

tappets or cam followers, push rods, rocker levers and valve crossheads. The camshaft is driven by the

crankshaft gear, and that means rotation of the crankshaft directs the action of the camshaft, which controls the

opening and closing sequence of the valves and the injection timing (fuel delivery).

FIGURE 1-6. Diesel Engine Cycles.

1-10

|

||

|

||