| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

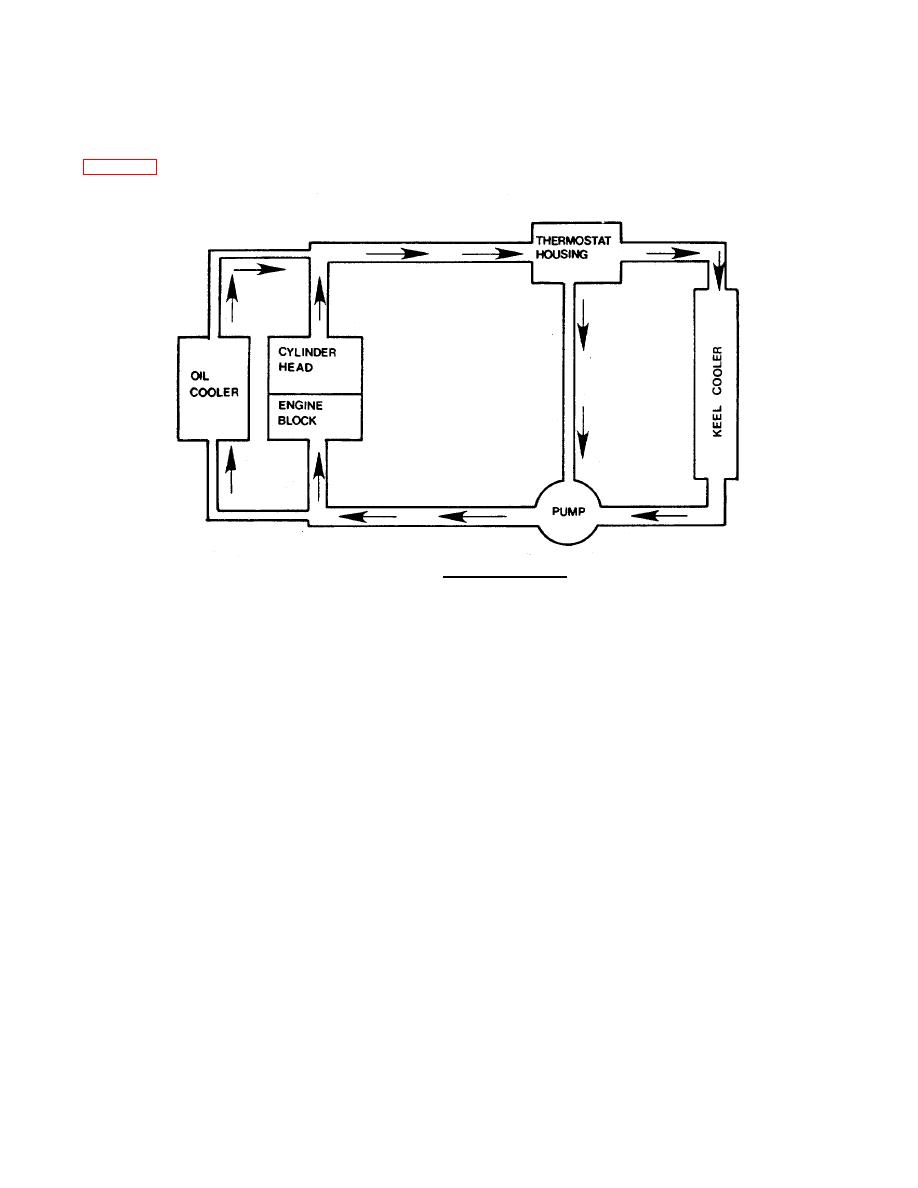

(1) Coolant Flow Path. Water (coolant) is circulated by a centrifugal water pump mounted on front of

the engine. The water pump is belt driven. Water circulates around wet-type cylinder liners, through the

cylinder heads, and around the injector sleeves. Injector sleeves, in which the injectors are mounted, are

designed for fast dissipation of heat. The engine has a thermostat to control engine operating temperature.

FIGURE 1-7. Coolant Flow Path.

(2) Water Filter. A water filter (corrosion inhibitor) bypasses a small amount of coolant from the

system through a filtering and treating element which must be replaced periodically. The filter protects the

cooling system from abrasive materials and debris.

(3) Cooling System Venting. The cooling system must be designed to allow air to escape while filling

the cooling system. During engine operation, coolant will continuously flow through the engine vent line to

remove air.

(4) Coolant Cooling. The engine coolant is cooled in a remote keel cooler. Sea water is circulated

through the cooler, around a tube bundle that has the engine coolant passing through, and back to the engine.

Heat contained in the coolant is dissipated by the keel cooler.

(5) Coolant. Use ethylene glycol antifreeze year-round to provide freeze point and boil-over protection

and always use good quality soft water in the cooling system. Refer to Army Technical Bulletin TB 55-1900-

207-24, Treatment of Cooling Water, for antifreeze and additive requirements.

(a) Antifreeze. A mixture of 50 percent water and 50 percent antifreeze is sufficient for freeze

protection to -34F (-37 ) and is used in the NTA 855-GC cooling system.

C

(b) Sealing Additives. Sealing additives are not used in the cooling system. They will build up in

the low flow areas and clog the cooling system.

1-13

|

||

|

||