| Tweet |

Custom Search

|

|

|

||

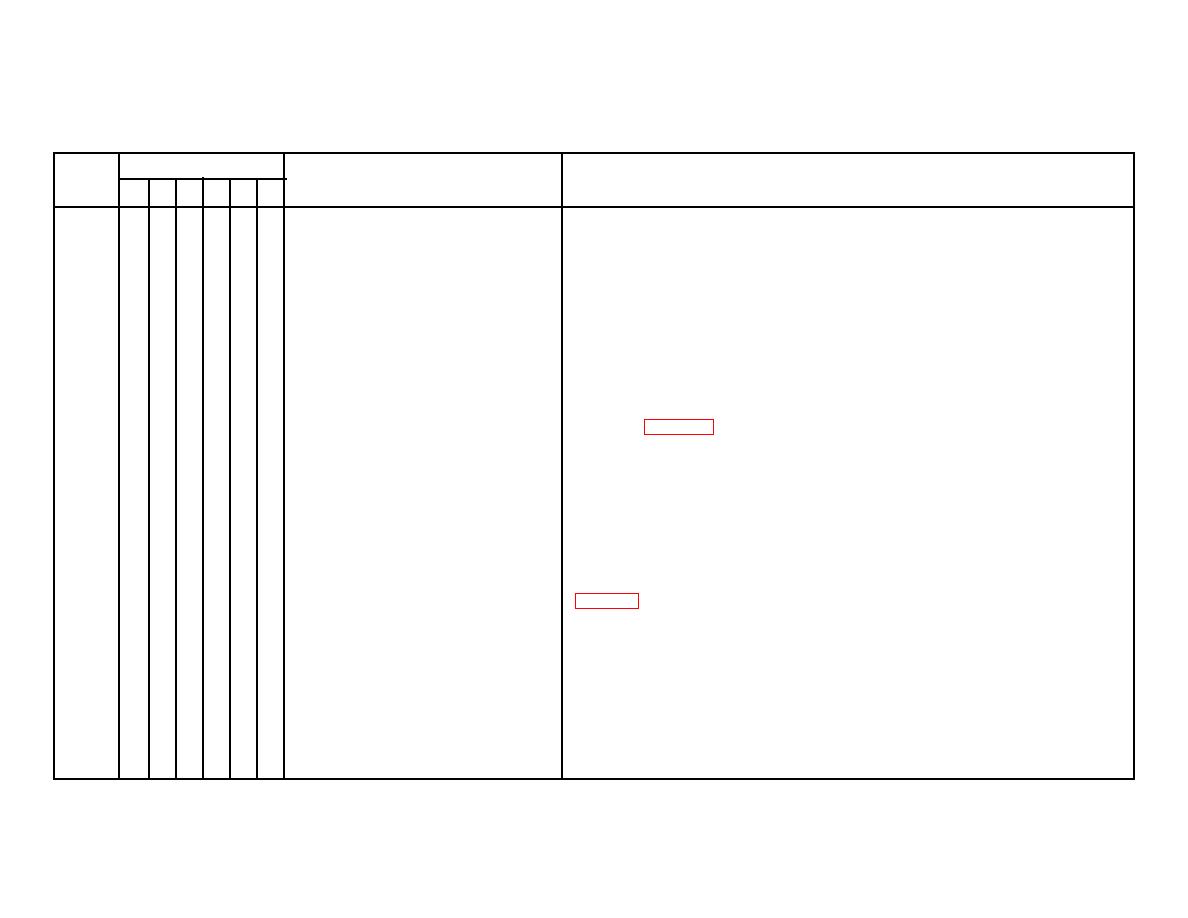

TM 55-1905-223-24-3

Table 2-1. Preventive Maintenance Checks and Services

D-Daily

M-Monthly

Q-Quarterly

A-Annually

B-Biennially

E-Every 1600 Operating Hours

Item

Interval

Items To Be

No.

DM

Q

A

B

E

Inspected/Serviced

Procedures

6

Intake Air System

Check all air connections for loose clamps or

connections, and tighten as required.

Check all hoses and tubing for cracks, punctures

and tears, and replace as required.

Check for collapsing hoses or tubing and other

damage, and replace as required.

Check filter warning indicator for intake air

restriction. The intake filter warning indicator

will change from green to red, indicating an

intake air restriction. Replace air cleaner element

if required (para. 2-29).

7

Throttle (Actuator)

Check for binding, loose fittings, and capscrews

that affect the smooth operation of the throttle

throughout its range. Secure capscrews, starting

at bottom, in 1/8 turn increments to 50 in-lb(5.6

N M).

Check for corrosion and clean as required.

8

Exhaust System

Check for exhaust leaks and correct as required

9

Make sure that air intakes and vents on the gen-

erator housing are free from dirt, debris, and

other foreign materials.

10

Engine (General)

Visually check for air, water, fuel or oil leaks.

Secure any loose connections,fittings, filter

elements or capscrews.

2-11

|

||

|

||