| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

NOTE

If the ring gear teeth are cracked or broken, the flywheel assembly must be

replaced.

b.

Clean and inspect flywheel housing as follows:

(1)

Use solvent to clean the housing.

(2)

Dry with compressed air.

(3)

Visually inspect all surfaces for nicks, burrs, or cracks.

(4)

Use a fine crocus cloth to remove small nicks and burrs.

(5)

Inspect all threaded capscrew holes for damage.

(6)

Replace the housing if threads or housing are damaged.

REPLACEMENT

a.

Install the flywheel housing (5, Figure 3-62).

CAUTION

If a new flywheel housing is being installed, the dowels must be removed from

the cylinder block prior to installing the housing to prevent damage to the

housing. The housing must be doweled with an oversize dowel after it has been

aligned. Refer to paragraph 4-15.

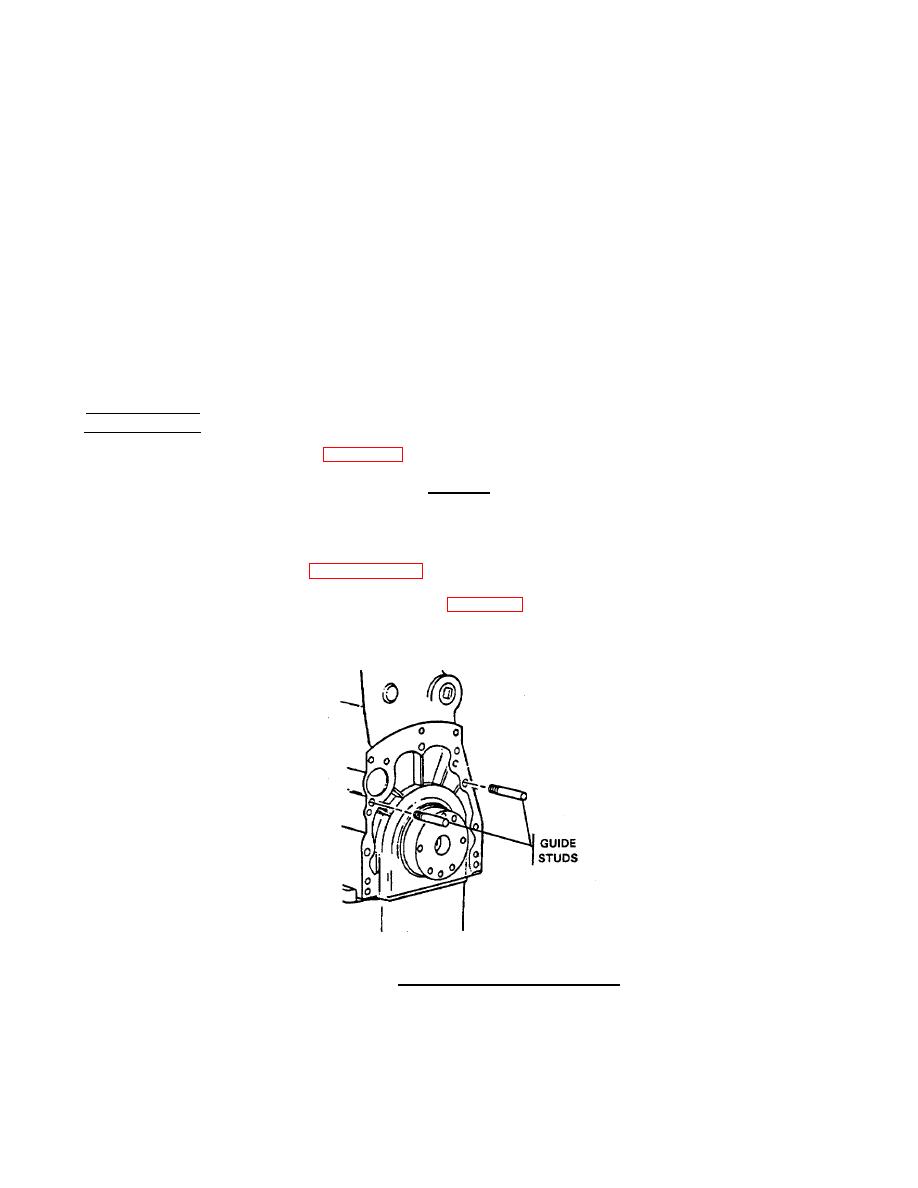

(1)

Install two 5/8-18 x 4 inch guide studs (Figure 3-68) in the cylinder block to help support

and align the housing during installation.

FIGURE 3-68. Housing Alignment Guide Studs.

3-117

|

||

|

||