| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

f.

Using an arbor press and steel tubing, press the two bearings onto the clutch shaft (34), one from each

end, with their back faces butting against the stop shoulder on the shaft (34).

g.

Install and secure the hand lever (42) to the operating shaft (47) with the hexhead capscrew (43).

Tighten the capscrew to 86-95 ft-lb torque.

h.

Install the clutch shaft (34) bearings attached into the shaft bore and bearing cup (37) in the PTO

housing (44); install the output end of the shaft (34) first. Slide the bearing cup (32) over the shaft and

into its bore in the PTO housing. Squarely press the bearing cup (32) in place against the bearing.

Install the bearing retainer (31) over the shaft (34).

i.

Adjust the bearing end play to 0.004-0.007 inch on the SP111 HP2 (0.006-0.010 inch on the SP 214

P1).

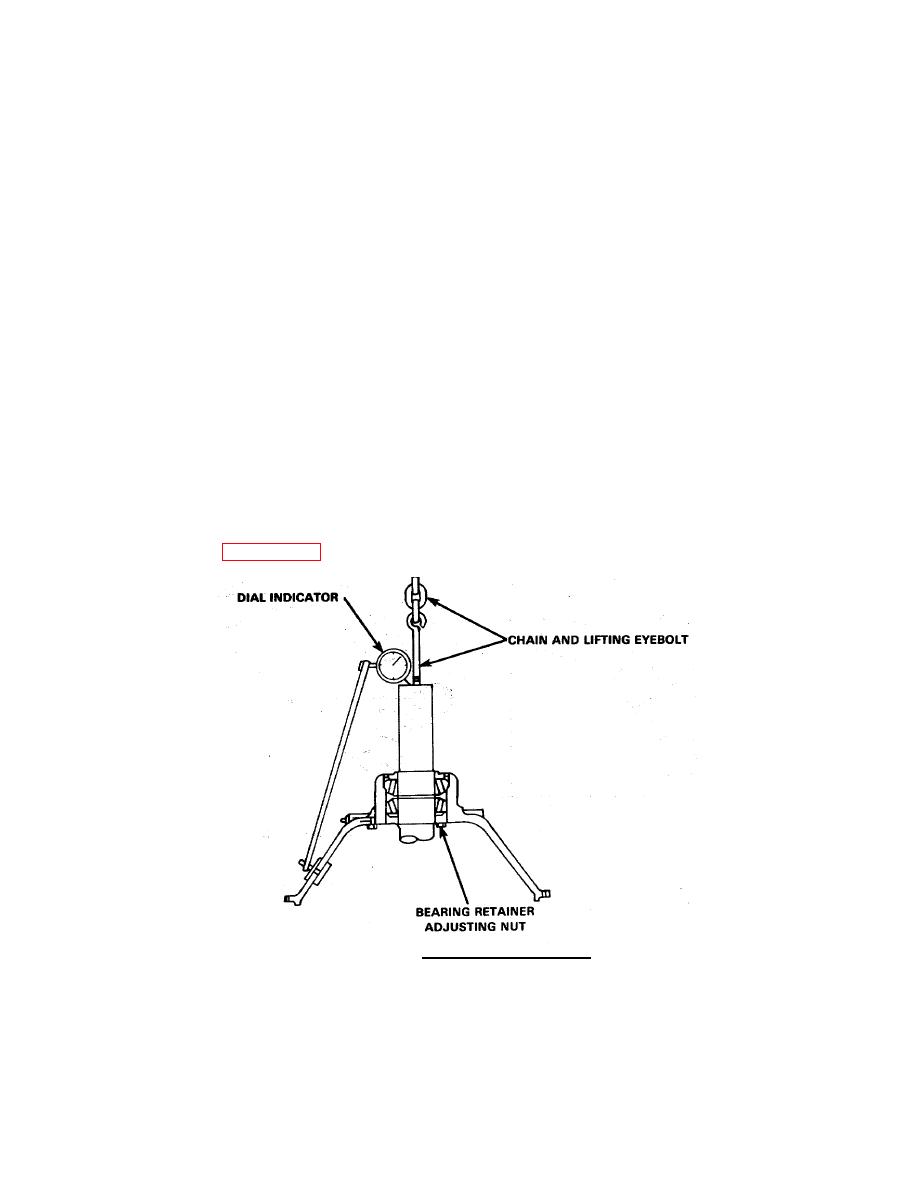

NOTE

The only approved method of field adjustment is by the use of a dial indicator to read

actual end play. The adjustment procedures are the same for both PTOs (except for end

play measurements).

On PTO units which have been disassembled, steps (a) through (i) of the Assembly

Procedures must be accomplished in order to reach a starting point for bearing

adjustment on the SP 111 HP2.

(1) Use the bearing retainer nut for adjusting the tapered roller bearings.

Refer to FIGURE 3-56.

FIGURE 3-56. Adjusting Roller Bearings..

3-83

|

||

|

||