| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

NOTE

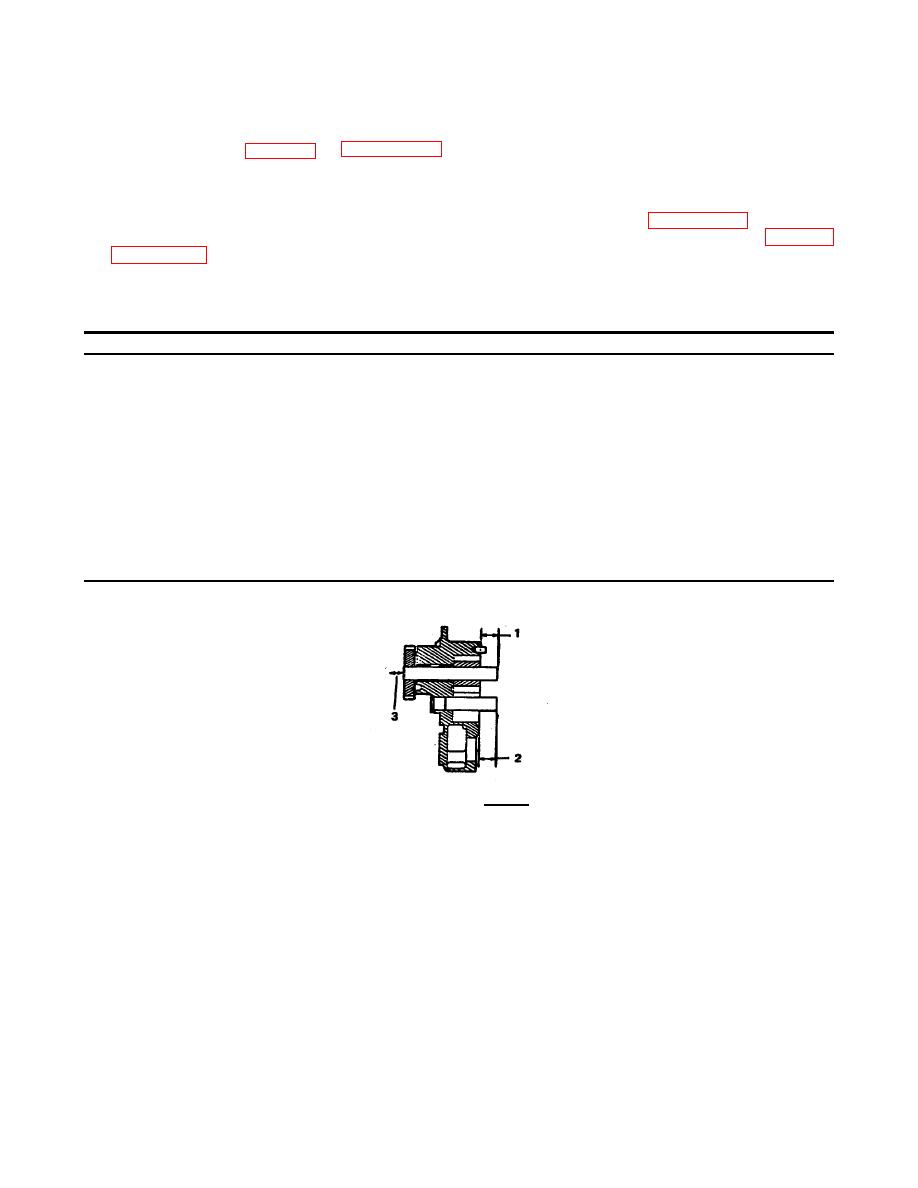

See Table 3-5 and FIGURE 3-68 for the correct idler shaft protrusion after it is

installed in the pump body.

d. Apply a coat of lubricating oil to the inside diameter of the driven gear (27, FIGURE 3-64). Install the

gear (27) onto the drive shaft (30). Use an arbor press to push the gear (27) onto the shaft (30). See Table 3-5

and FIGURE 3-68 to find the correct amount of protrusion .the drive shaft must have after the gear is installed.

Table 3-5. Oil Pump Shaft Limits - Inch (mm)

Minimum

Maximum

Single Oil Pump

Drive Shaft

Protrusion 1

0.855

0.875

(21.72)

(22.22)

Idler Shaft

Protrusion 2

0.720

0.740

(18.29)

(18.80)

Drive Shaft End

0.0002

0.0005

3 Movement

(0.05)

(0.13)

SINGLE

FIGURE 3-68. Limits.

e.

Install the drive shaft (30) from the gear pocket side of the pump body, into the bore in the pump body

(31). Apply a coat of lubricating oil to the inside diameter of the drive gear(s) (34). Put the gear (34)

on the shaft (30) on the side of the body opposite to the gear pockets; use an arbor press to push the

gear (34) onto the shaft (30). There must not be-more than 0.012 inch (0.030 mm) clearance between

the gear (34) and the body (31).

3-107

|

||

|

||