| Tweet |

Custom Search

|

|

|

||

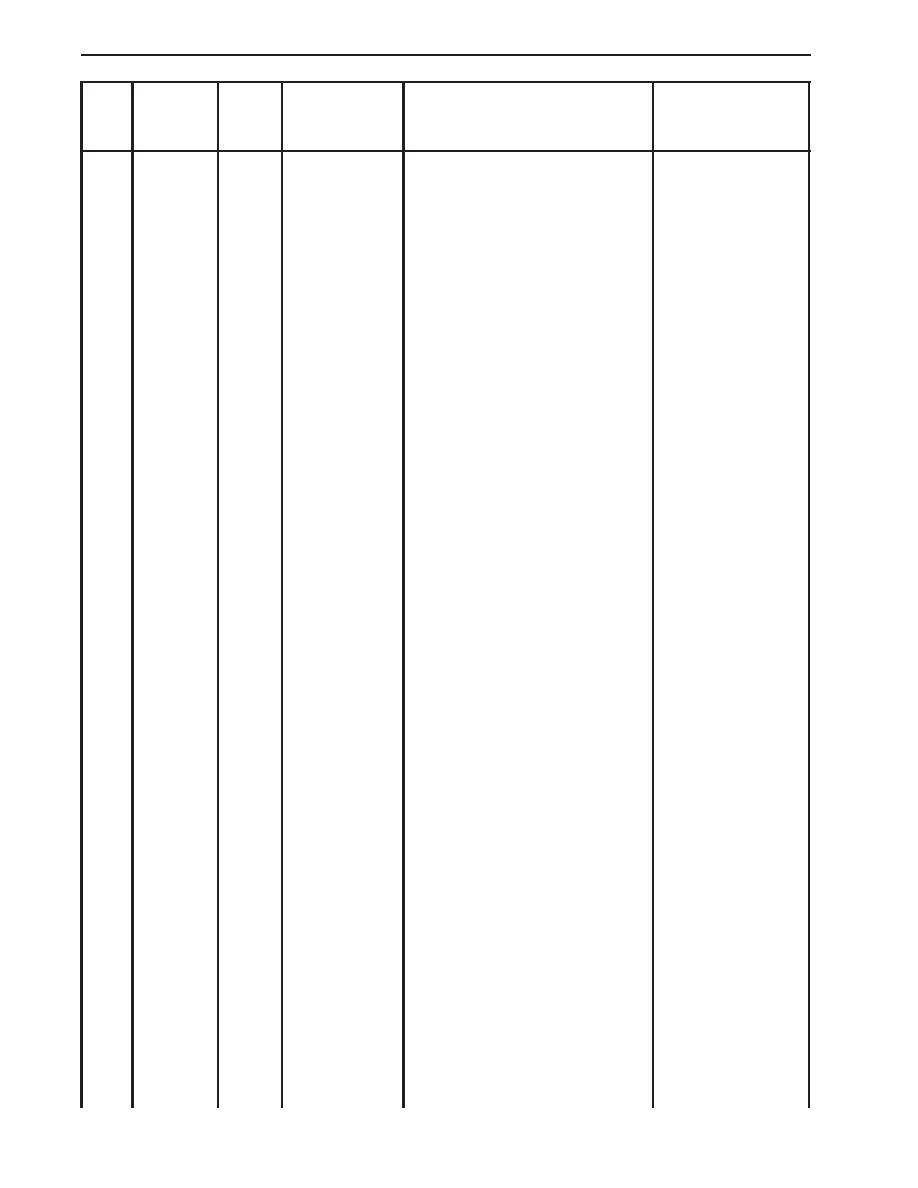

TM 55-1905-242-14

0053 00

ITEM

INTERVAL

MAN-

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR

CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

Monthly

4.0

Inspect voids for any damage or

Voids are not water-

deterioration (hull pierced, rust, etc.).

tight.

Check for signs of water, oil, or other

signs of leakage into compartments.

Check for any unusual signs of stress

to the structure.

Monthly

8.0

Pump bilges.

FOREDECK

89

Ramp Winch

Monthly

1.0

Winch Assembly

Apply two or three shots of grease to

the fittings on the lever arms specified

in table 1.

0.5

Fill the final drive assembly to the level

of the filler plug with lubricant specified

in table 1.

0.5

Fill the final drive assembly to the level

of the filler plug with lubricant specified

in table 1.

90

Ramp Assembly

Monthly

0.3

a. Latch

Apply two or three shots of grease to

Mechanism

the grease fittings on the latch mechan-

ism. Clean surrounding area as neces-

sary following greasing. See table 1.

Monthly

0.5

b. Hinge

Apply four to six shots of grease to

Assembly

each of the grease fittings on the hinge

bosses. See table 1.

Monthly

0.2

c. Ramp

Inspect ramp for dents, cracks, rust, or

Ramp does not provide

other damage that will inhibit safe

watertight integrity

functioning of the ramp.

while underway.

Scrape to remove rust, then prime and

paint as necessary per TM 43-0144.

Monthly

1.5

d. Cables and

Inspect cables and sheaves for wear

Cable is damaged.

Sheaves

and serviceability. Pay out cable and

check for reduction of rope diameter

Sheaves will not rotate

beyond its nominal value; worn or

or hold cable to guide

broken outside wires; severe bending,

it.

kinking, crushing, caging, or a popped

core; or evidence of damage due to

welding or other heat sources.

0053 00-16

|

||

|

||