| Tweet |

Custom Search

|

|

|

||

TM 55-1915-200-SDC

Section IV. QUICK-SEALING LEAKS AND CRACKS

8-11. METHODS. Quick action in sealing leaks and cracks can prevent further flooding or even advance the flooding

boundary back to the area of damage. The following paragraphs describe a number of methods for sealing leaks and

cracks.

a. Crack in steel plate. A fairly common type of leak is caused by a crack in a steel plate. When the leak is in a flat

surface away from frames and other interferences, generally it can be stopped by scraping the surface smooth and

applying a patch of sheet packing backed by a shole which can be held in place with shoring.

b. Crack adjacent to frame. When the crack is adjacent to a frame, it may be necessary to use oakum held in place

by the corner of a timber. Advantage should be taken of adjacent framing to use clamps for holding the stopper in place.

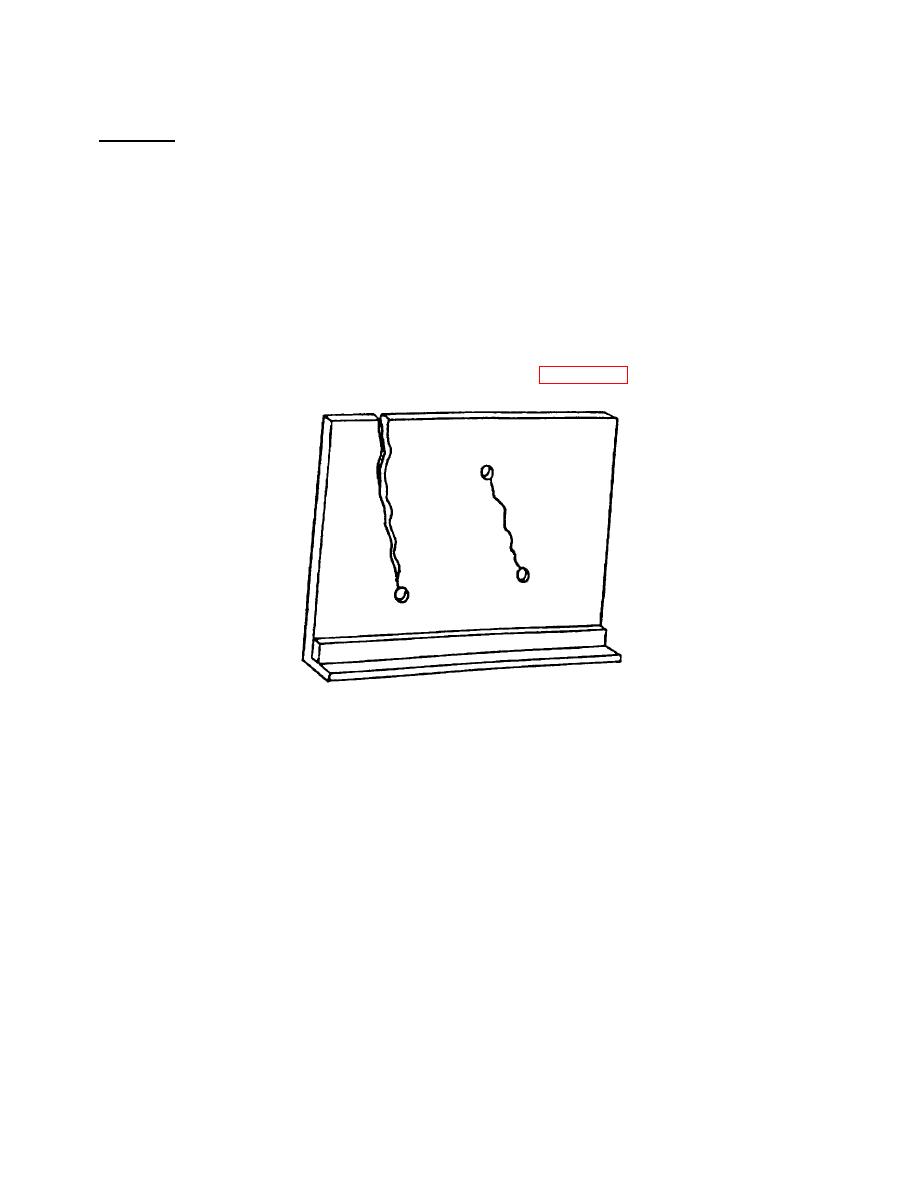

c. Torn plating. Upon reinspecting a crack, it may be found that it has increased in length. The plating is being torn

like paper. To prevent further cracking, drill quarter-inch holes at the extreme ends of the crack, and plug the holes. If

there is time, weld a plate over the crack. This technique is illustrated in FIGURE 8-2.

FIGURE 8-2. Controlling Cracks.

8-10

|

||

|

||