| Tweet |

Custom Search

|

|

|

||

b. Preliminary Preparation for Movement.

Tug is capable, and. For coordinating the basic motions

to perform the specific tasks for which the equipment

(1) Perform preventive maintenance checks

was designed. Since nearly every job presents a

and services (tables 3-1 and 3-2).

different problem, the operator may have to vary given

(2) Prior to actually starting the equipment, the

procedures to fit the. Individual job.

following auxiliary equipment must be either operating,

set for automatic operation, or in a standby condition as

shown in table 2-8.

NOTE

Before operating the harbor tug, all

personnel must be thoroughly

familiar with TM 55-501.

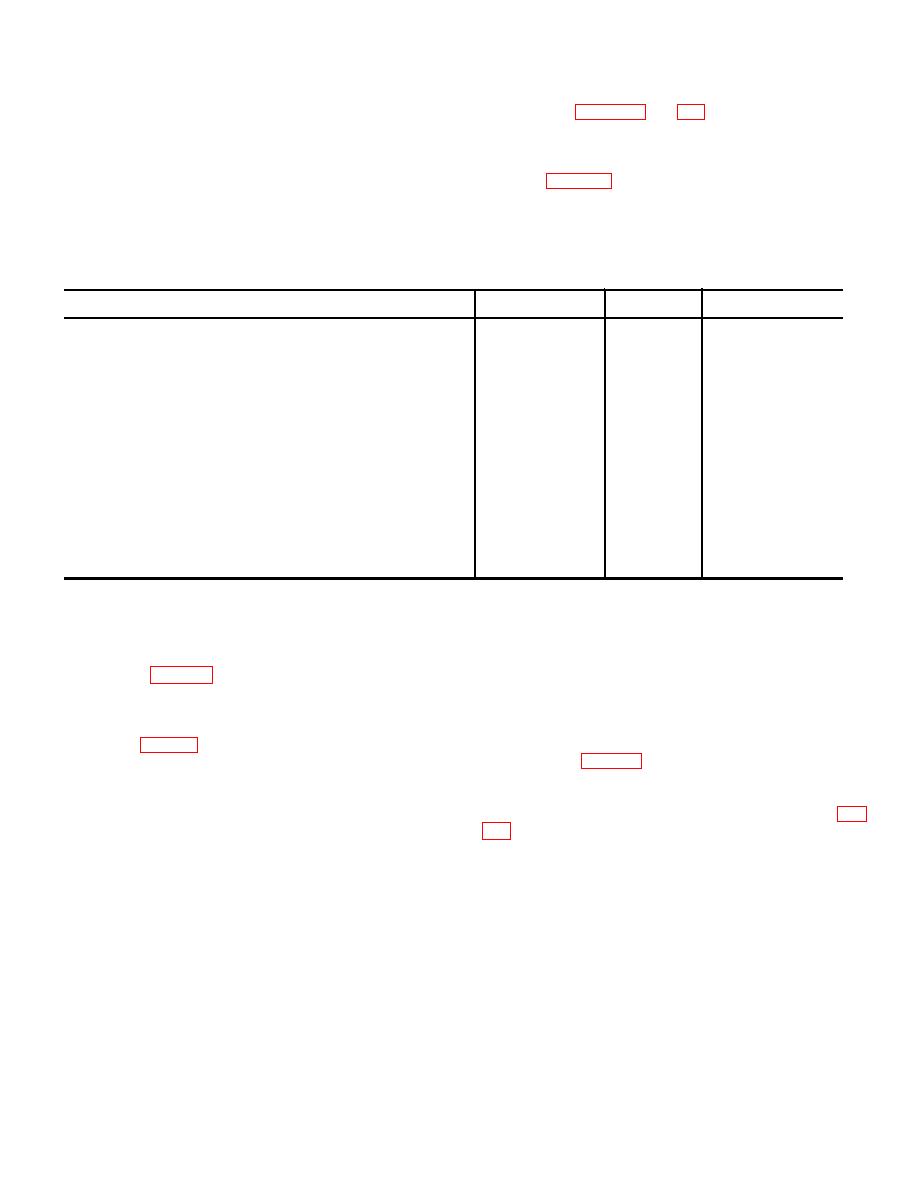

Table 2-8. Machinery Status Prior to Getting Underway.

Equipment

Operating

Auto

Standby

Generator set No. 1............................................................................. X

Generator set No. 2.............................................................................. .......................... ......................... X

Fire and salvage pump ......................................................................... .......................... ......................... X

Bilge and ballast pump ......................................................................... .......................... ......................... X

Fire pump ............................................................................................ .......................... ......................... X

Fresh and salt water standby pump ..................................................... .......................... ......................... X

Steering motor .................................................................................... X

Fuel oil transfer pump .......................................................................... .......................... ......................... X

Lubricating oil transfer pump ................................................................ .......................... ......................... X

Lubricating oil standby pump............................................................... X

Ventilating fans .................................................................................... ......................... X

Air compressor No. 1 ........................................................................... ......................... X

Air compressor No. 2 ........................................................................... ......................... X

Water pressure set ............................................................................... .......................... ......................... X

Searchlight .......................................................................................... X

Engine order telegraph transmitter....................................................... X

Anchor windlass ................................................................................... .......................... ......................... X

Heating unit boiler (see note 1) ............................................................ X

1

Operating to furnish domestic hot water. or both heat and hot water, depending on the climatic conditions.

counter indicates the correct number of turns per minute

2-4. Starting-Ahead from Stop (Propulsion Engine)

for the speed desired. The governor hand control (4) is

used in conjunction with the throttle handwheel to obtain

a. At the Pilot house. Place the engine order

a fine speed adjustment when required.

telegraph (8, fig. 2-1) at the desired AHEAD speed

position.

2-5. Starting-Astern from Stop

b. In the Engine room.

(1) Acknowledge message on engine order

a. At the Pilothouse. Place the engine order

telegraph (1, fig. 2-3).

telegraph (8, fig. 2-1) at the desired ASTERN speed

(2) With throttle handwheel (5) pointer at the

position.

extreme clockwise position, turn the governor hand

b. In the Engineroom.

control (4) to the extreme counterclockwise RUN

(1) Acknowledge engine order telegraph (1, fig.

position.

(3) Quickly turn the astern-ahead handwheel (6)

(2) With the throttle handwheel (5) pointer at

counterclockwise from stop past the AHEAD position to

the extreme clockwise position, turn the governor hand

START. As soon as the engine starts move the astern-

control (4) to the extreme counterclockwise RUN

ahead handwheel clockwise to AHEAD position.

position.

(4) The engine should now be turning over at

slow speed and firing on all cylinders.

(3) Quickly move the astern-ahead handwheel

(6) full clockwise past astern to START. As soon as the

engine starts, move the astern-ahead handwheel

CAUTION

counterclockwise to ASTERN.

Do not run engine continuously

(4) The engine should now be turning over at

between 165 and 200 rpm. Do not

slow speed and firing on all cylinders.

run engine in excess of 200 rpm until

(5) Move the throttle handwheel (5)

engine heat exchanger water outlet

counterclockwise until the engineroom rpm indicator

temperature has reached 130oF.

shows the correct number of turns for the desired speed.

Use the governor hand control (4) in

(5) Move the throttle handwheel (5)

counterclockwise until engineroom revolution (rpm)

2-22

|

||

|

||