| Tweet |

Custom Search

|

|

|

||

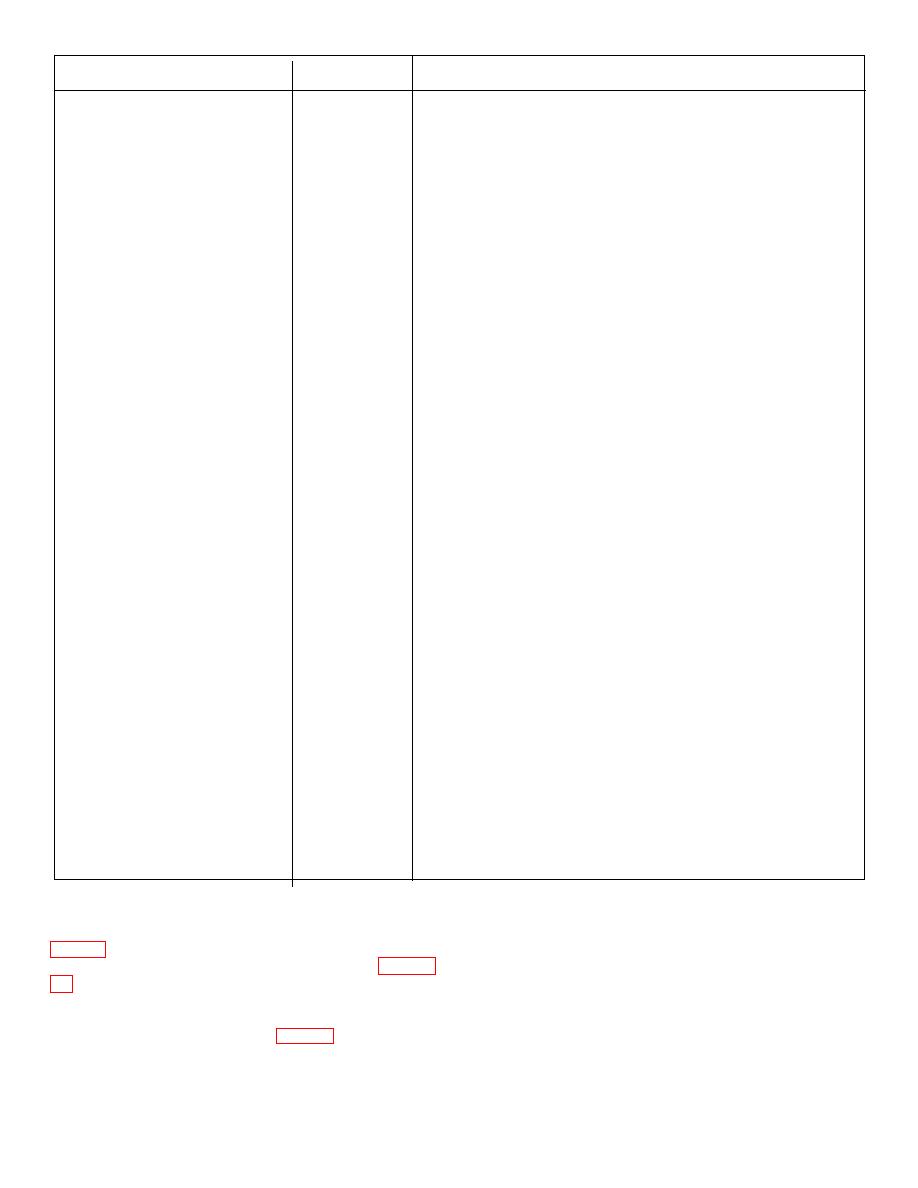

Operation

Open valve

Procedure

Supply fire water to deck using fire

(6)*

Connect hose to deck fire station. Start port and/or starboard

and salvage pump (s).

(7)*

fire and salvage pump as required. When finished secure

(9)*

pump(s). Secure all valves.

(14)**

*Open only if port pump is used.

(13)**

**Open only if starboard pump is used.

(11)**

(17)

Supply fire water to fire main from

(2)

Connect shore supply to valve (2) or (22) as required. Close valve

shore.

(22)

not being used. To fight fire, open valve (3) (4), (20) or (21) as

,

necessary.

CAUTION

Do not connect shore supply to valve (3) or (21). Check to be

sure that valve (17) is closed. Do not operate fire pump when

connected to shore supply to prevent contamination of shore

supply water system.

Supply fire water to forward fire

(6)

Start both fire and salvage pumps. Open valves on monitor

monitor.

(7)

and position monitor to obtain desired water trajectory.

(9)

Secure valve on monitor when finished. Secure both pumps.

(14)

Secure all valves.

(13)

(11)

(10)

Use starboard fire and salvage pump

(12)

Connect hose to starboard salvage connection and drop

in salvage operation from star-

(11)

strainer end into area to be pumped. Start starboard fire and

board side.

(5)

salvage pump. When finished, stop pump and secure all valves.

Salvage operation using both fire

(15)

Connect hose to port or starboard salvage connection. Start

and salvage pumps.

(12)

both fire and salvage pumps. When finished, secure both

(11)

pumps. Secure all valves.

(8)

(9)

(5)

Wash decks

(19)

Start electric fire pump. Secure pump when finished. Secure

(18)

all valves.

(1)

(23)

Supply fire water to aft fire

(6)

Start both fire and salvage pumps. Open valves on monitor

monitors.

(7)

and position monitors to obtain desired water trajectory.

(9)

Secure both pumps. Secure all valves.

(14)

(13)

(11)

(16)

(24)

(25)

Use port side fire and salvage pump

(8)

Connect hose to port salvage connection and drop strainer

in salvage operation from port

(9)

end into area to be pumped. Start port fire and salvage

side.

(5)

pump. When finished, stop pump and secure all valves.

(4) Bilge and ballast pump operation.

sectional cast iron steam boiler, a 3-1/2 gpm tankless

hot water heater, and an oil burner driven by a fractional

(a) Move bilge and ballast pump switch (20,

1/4 hp electric motor. Heat is distributed throughout by

means of convecting piping, unit heaters, convectors,

(b) Position valves to task required (table 2-

and heating coils. Two unit heaters are located in the

engineroom, and one in crews quarters.

Two

(c) To secure the pump, close bilge or

convectors are located in crews washroom; six in the

ballast valves, then press STOP push switch at pump

pilothouse; one in the captain's stateroom; one in the

and move bilge pump switch (20, fig. 2-5) to OFF,

chief engineer's stateroom; one in the passage way; two

in the crews mess hall; one in the officer's

2-21. Heating System Operation

2-55

|

||

|

||