| Tweet |

Custom Search

|

|

|

||

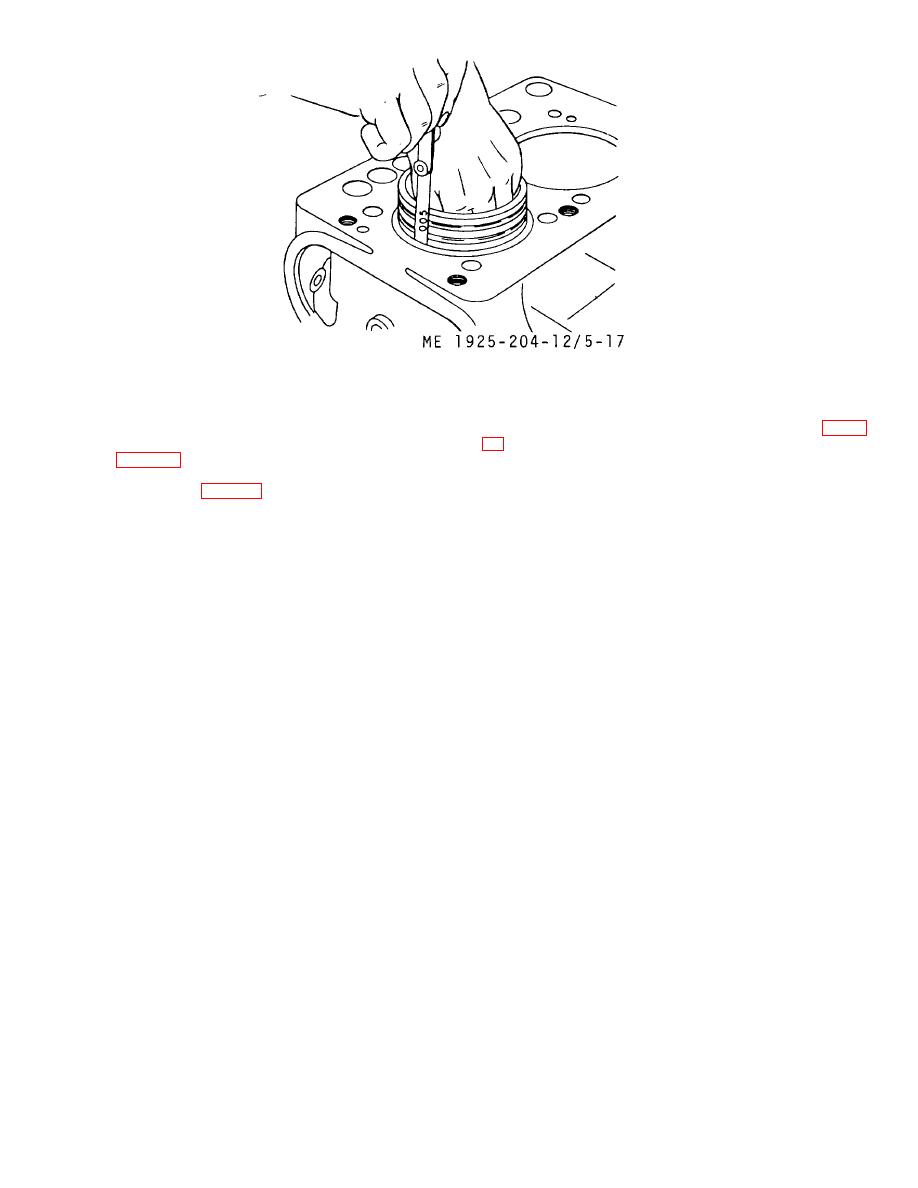

Figure 5-17. Measuring piston clearance.

(6) Inspect cooling surface on under side of the

diameter of the sleeve bearing is more than 1.5030 inch,

piston head. A coating of carbon indicates failure of cooling

replace the sleeve bearing.

oil supply through the drilled passage in the connecting rod.

(8) Fit piston rings into cylinder liner bore (fig. 5-

Clean the orifice at bottom of connecting rod, and the spray

nozzle (9, fig. 5-16) at the top to correct the trouble.

liner, use a piston to push ring into liner bore. Measure the

(7) Inspect and measure inside diameter of piston

end gap for compression rings at from 0.020 to 0.030 inch

pin sleeve bearings (12, fig. 5-16). If clearance exceeds 0.010

(0.025 to 0.040 inch for. chrome compression rings). Gap on

inch, determine whether pin or bearing is worn. If pin

oil control rings should be between 0.010 to 0.020 inch. The

diameter is less than 1.4990 inch, replace pin. If inside

gap may be increased to minimum, by clamping a thin, flat,

fine mill file in a vise and drawing ring ends across the file.

5-21

|

||

|

||