| Tweet |

Custom Search

|

|

|

||

(11) Fill the fresh water cooling system, after

reconnecting fuel and raw water lines to the engine.

(12) Install starter and generator (para 5-2).

(13) Reconnect the power generator to engine

5-5. Cylinder Liner

a. General. The replaceable type cylinder liner is

accurately machined and heat treated to provide a long

wearing, scuff resistant surface. A flange at the top fits into a

counterbore in the cylinder block and rests on a replaceable

cast iron insert which permits accurate alignment of the liner.

Compression is sealed with an individual laminated

compression gasket for each cylinder. The liner is cooled by

the waterjacket in block, and by the scavenging air furnished

by the blower, through air inlets in liner.

NOTE

If necessary, the air inlet ports may be

cleaned without removing the liner.

b. Cleaning the Installed Liner.

(1) Remove the cylinder head (para 5-3).

(2) Remove the air box handhole covers.

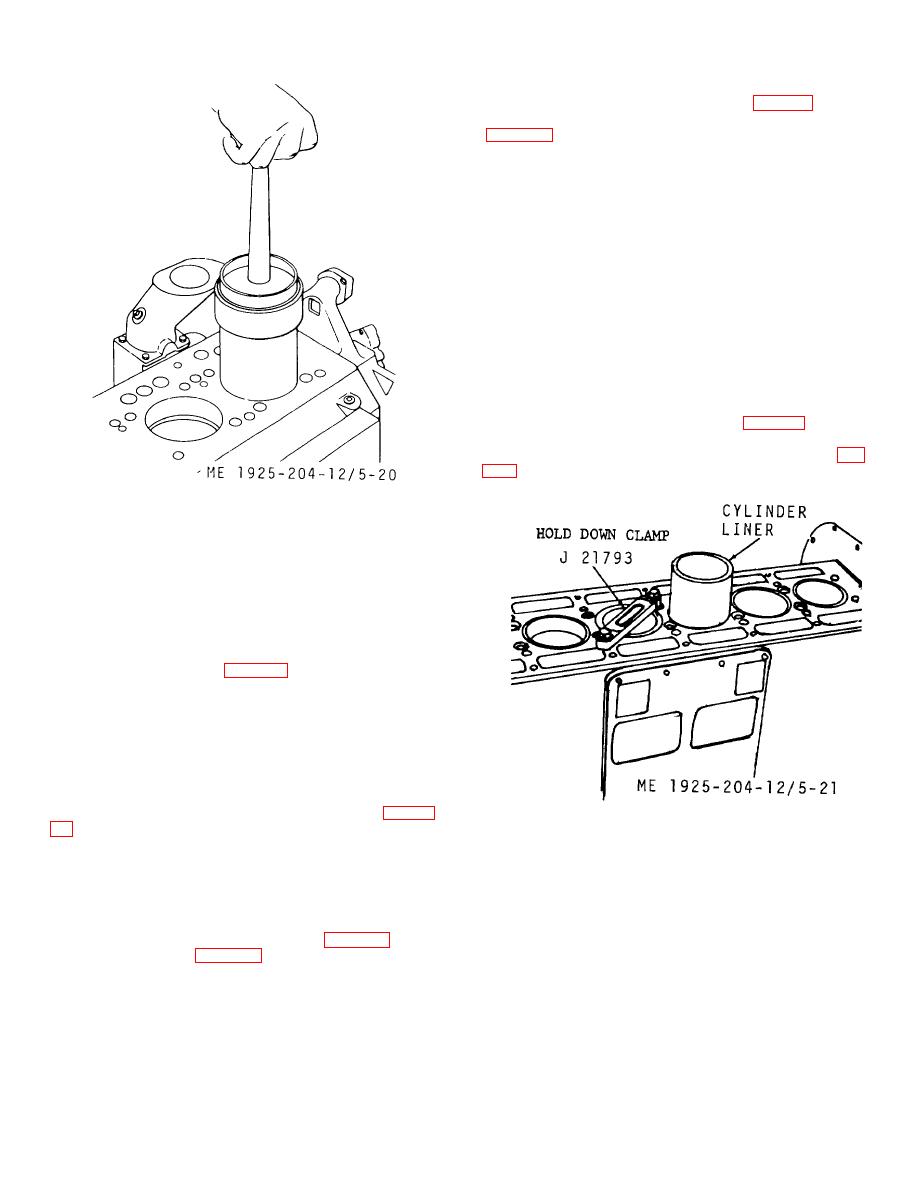

(3) Install a cylinder liner hold down clamp (fig.

Figure 5-20. Compressing the piston rings.

NOTE

Compressors are not always wide enough

to compress six rings of this size at once.

If this is true here, compress the bottom

pair first, until they have entered the liner,

then move compressor to the top four.

(3) Wipe clean, then lubricate journal. Position

the upper bearing half (5, fig. 5-16) (the one with a short

groove at each parting line) in the connecting rod, and

position the rod and bearing half on the journal.

(4) Note match marks on bearing caps. Install

lower bearing half in bearing cap with tang of bearing half in

groove of cap. Position the cap and bearing, then install bolts

(7) through rod and cap. Torque bolts to 50 ft. lbs. and

install new cotterpins.

(5) Install remaining pistons in a similar manner.

(6) Install lubricating oil pump and screen (para 5-

Figure 5-21. Cylinder liner hold down clamp.

(7) Position a new oil pan gasket on pan, position

pan under block, and secure with lockwashers and capscrews.

(4) Turn engine over until the piston of the liner

(8) Tighten hoist, remove blocks from under

whose ports are to be cleaned, is at the bottom of its stroke.

engine, then slide engine to engine mount while guiding it onto

(5) Position a cloth on top of piston, to catch

pilot pin in generator housing and in position to receive the

carbon removed from liner ridges and ports. Clean all ridges

mounting bolts. Lower engine when in place.

and ports with a suitable tool or a hardwood stick, from the

(9) Replace the cylinder head (para 5-3) and all

inside of each liner.

accessories removed (para 5-2) in reverse order of their

removal.

(10) Fill crankcase with engine oil (LO 55-1925-

204-12-5).

5-24

|

||

|

||