| Tweet |

Custom Search

|

|

|

||

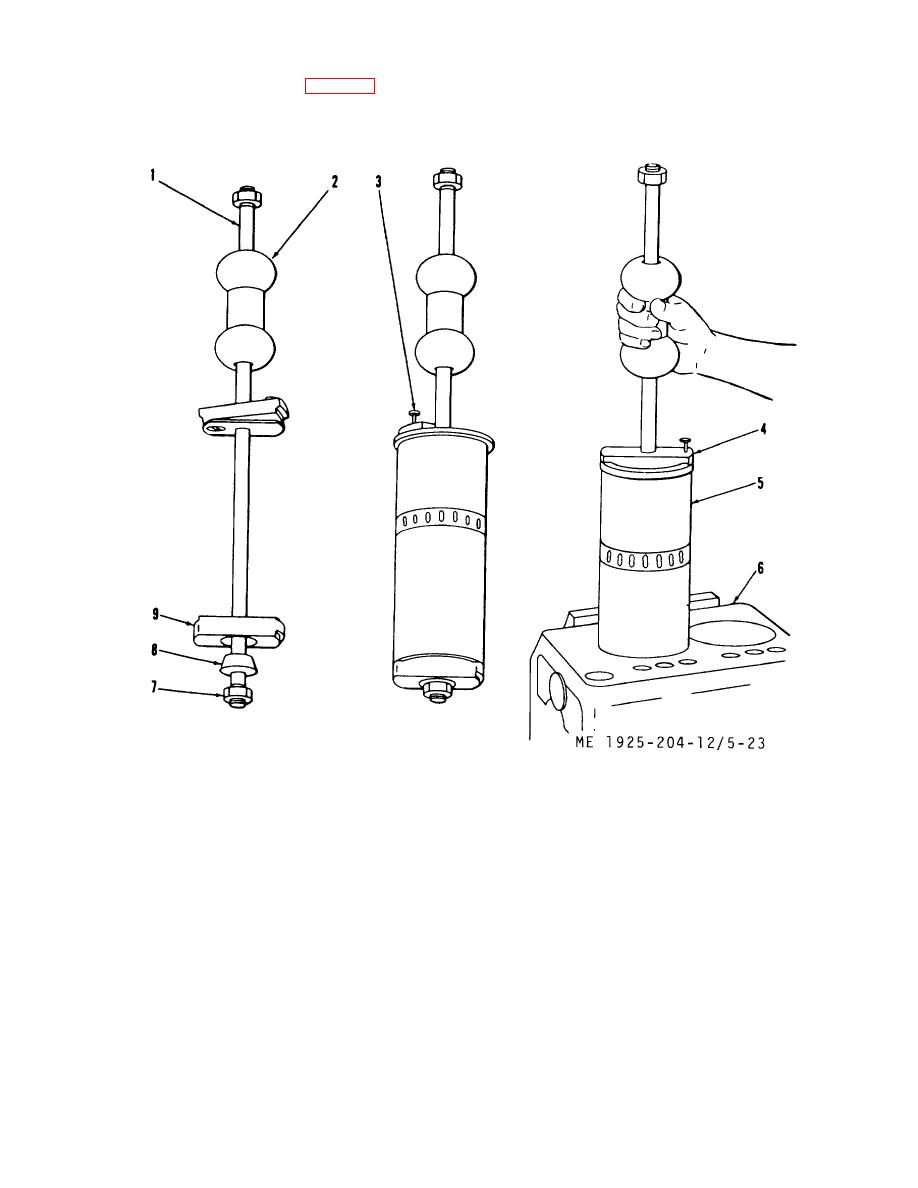

(4) When necessary, remove liner with tool as

completely through liner, clamp will seat in a horizontal

position.

follows: cock the lower puller clamp (9, fig. 5-23) on puller

rod (1), so rod will slip through the liner. When rod is

1.

Puller rod

6.

Cylinder block

2.

Puller weight

7.

Nut

3.

Puller clamp release

8.

Washer

4.

Puller clamp, upper

9.

Puller clamp. lower

5.

Cylinder liner

Figure 5-23. Cylinder liner removal.

(5) Slide upper puller clamp (4) against top edge

soda or lye solution long enough to loosen the carbon

of liner. With puller tool in place, strike head of puller rod (1)

deposits.

a sharp blow with puller weight (2)

(2) Final cleaning may then be accomplished by

(6) Remove cylinder liner from cylinder block.

brushing carbon away from ports.

Remove tool from liner, then remove liner insert from

(3) Inspect the cylinder liners for cracks, scoring,

counterbore of the block.

poor contact of outer surfaces, flange irregularities, inside

diameter, out-of-round, or

d. Cleaning and Inspection.

(1) When fuel oil washing does not remove all

carbon deposits, the liners may be soaked in a hot caustic

5-26

|

||

|

||