| Tweet |

Custom Search

|

|

|

||

disconnect pigtail from panel, remove cotter pin (15), cup

(b)

Energize circuit, push START button and

washer and contact spring (14), and lift off contact. Replace

observe voltage reading when accelerating contactor closes.

in reverse order of removal.

This contactor should close at 70 percent of line voltage.

Adjust to this valve with adjusting nut (8, fig. 5-82).

(2)

Replacement of contacts as follows:

NOTE

(a)

To replace stationary contact (2), remove

Contacts should be replaced in sets and

nut and screw (3) and lift off contact. Replace in reverse order

aligned to see that contacts meet squarely.

of removal.

(b)

To replace movable contact (1):

(c)

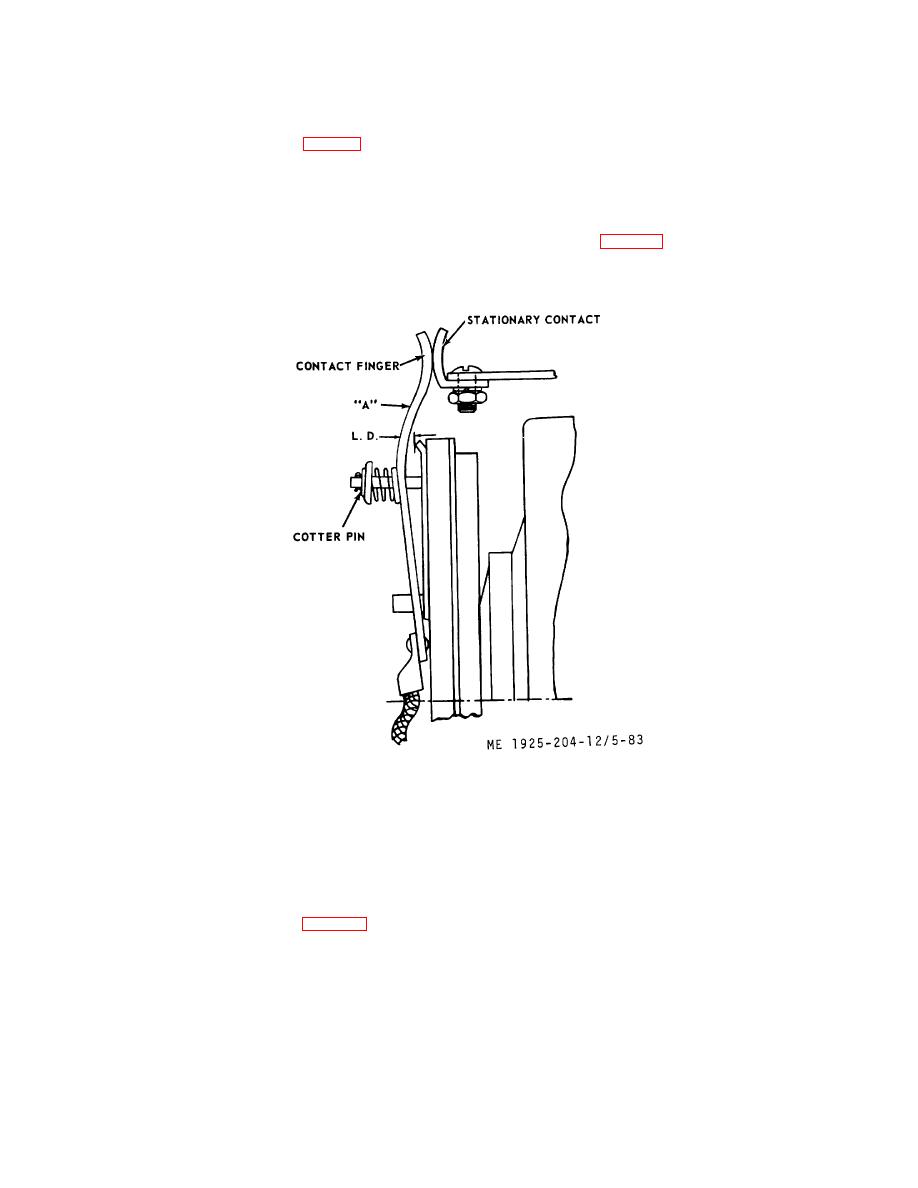

After contacts are replaced, check "Lead

Dimension" (L.D.) (fig. 5-83). This dimension should be 1/16

inch, and can be obtained by bending the movable contact at

"A."

Figure 5-83. Lead dimensions.

(3)

Coil replacement as follows:

(e)

Remove screw (6) from back of panel and

(a)

Remove external wiring connections from

lift coil (13) and core (7) from panel.

panel.

(f)

Slip coil from core.

(b)

Remove four mounting bolts and lift panel

from enclosure.

NOTE

(c)

Disconnect electrical connections from

If coil has been overheated, check all parts

coil.

for deposits of melted insulation that

(d)

Remove hairpin (12, fig. 5-82) and shaft

might

interfere

with

operation

of

(10). This permits

armature (11) to swing away from front of

contactor, and remove such deposits.

coil (13).

(g)

Replace coil in reverse order of removal.

5-111

|

||

|

||