| Tweet |

Custom Search

|

|

|

||

TM 55-1925-204-12

solenoids in the brake which in turn removes pressure on

(5) Pull bearing from worm gear shaft.

brakeshoes.

CAUTION

b. Maintenance and Adjustment.

Do not spin bearings with compressed air.

(1) Lubricate in accordance with LO 55-1925-204-12-

(6) Replace bearing if bearing runs rough when spun,

4.

while holding in hand.

(2) Inspect brushes for wear. Replace brushes worn

(7) Assembly is in reverse order of disassembly.

to one-half normal length. Sand new brushes to contour of

Replace housing cover and bearing cap gaskets, if necessary,

commutator.

on assembly.

(3) Check brushes for freedom in brush holders.

(8) Fill capstan gearbox with lubricant in accordance

Brushes should slide freely in holders. Clean and free

with LO 55-1925-12-4.

brushes that stick in holders.

(4) Inspect commutators for cleanliness and wear.

5-66. Motor and Brake

Clean dirty commutators, using 00 sandpaper if necessary.

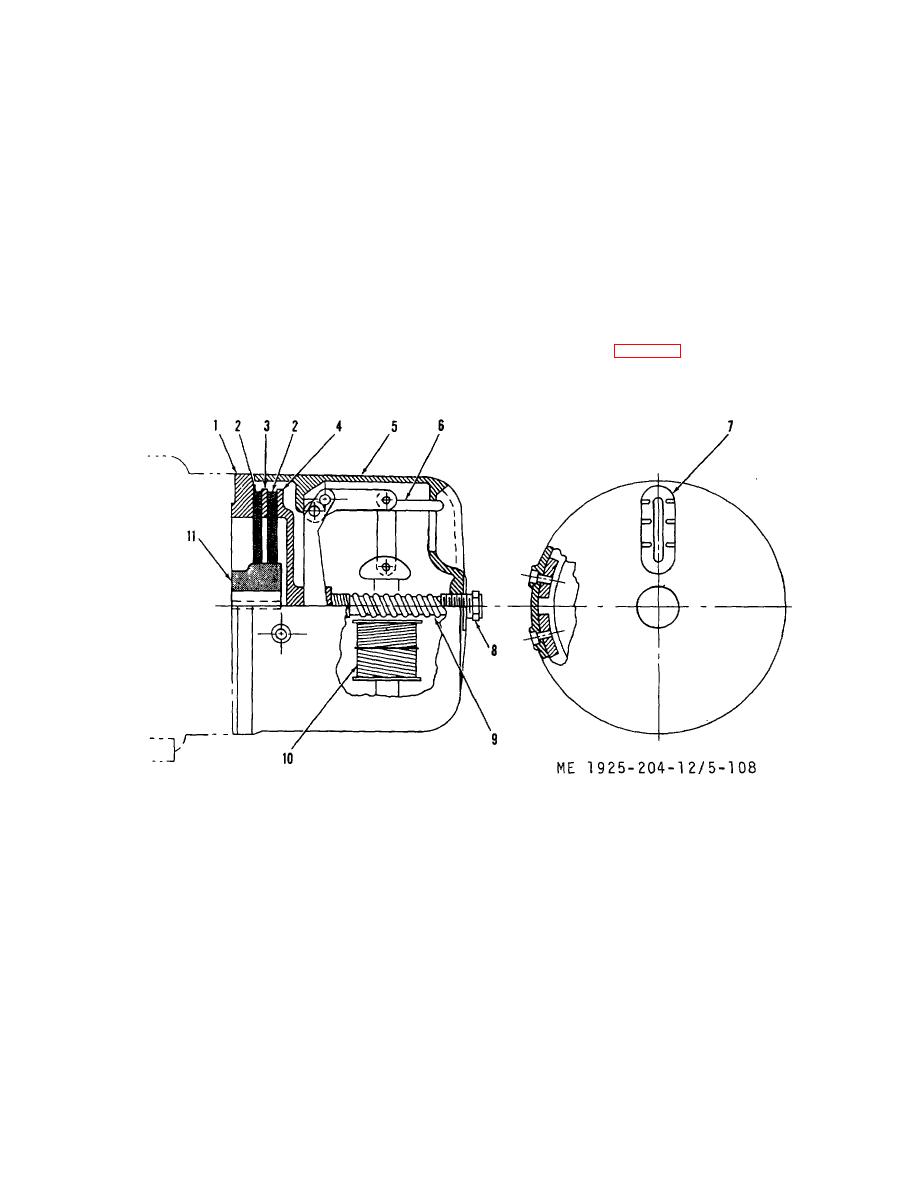

a. General. The motor is a 10-hp, 115-volt dc motor

(5) Adjust brush tensions to 1 1/2 to 2 1/2: psi spring

capable of turning at 1750 rpm in either direction. The motor

scale pull.

drives the capstan through a series of worm, pinion, and bevel

(6) To adjust motor brake release spring pressure,

turn adjusting nut (8, fig. 5-108) counterclockwise.

motor is equipped with a dry-type shunt brake which remains

set until such time as current is applied to motor. Application

of current to rotate the motor in either direction, energizes

Figure 5-108. Motor brake, capstan.

1. End plate

7. Cover plate

2. Rotating disc

8. Adjusting nut

3 Stationary disc

9. Spring

4. Pressure plate

10. Coil

5. Housing

11. Hub

6. Manual release and wear indicator

(7) Compensate for lining wear by turning slotted

c. Removal.

stud in center of adjusting nut (8) counterclockwise. This

(1) Disconnect wiring from motor.

adjustment is necessary when indicator (6) points to position

(2) Position a chain fall and support motor and brake

marked ADJUST on cover plate (7).

assembly.

(3) Remove six capscrews which hold motor to

adaptor plate.

5-148

|

||

|

||