| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

(6) After installing the injectors in the engine,

perform a complete engine tune-up. However, if only one

injector has been removed and replaced and the other

injectors and the governor adjustment have not been

disturbed, it will only be necessary to adjust the valve

clearance and time the injector for the one cylinder, and

to position the injector rack control levers. Refer to

paragraph 431 to position the rack control levers.

e

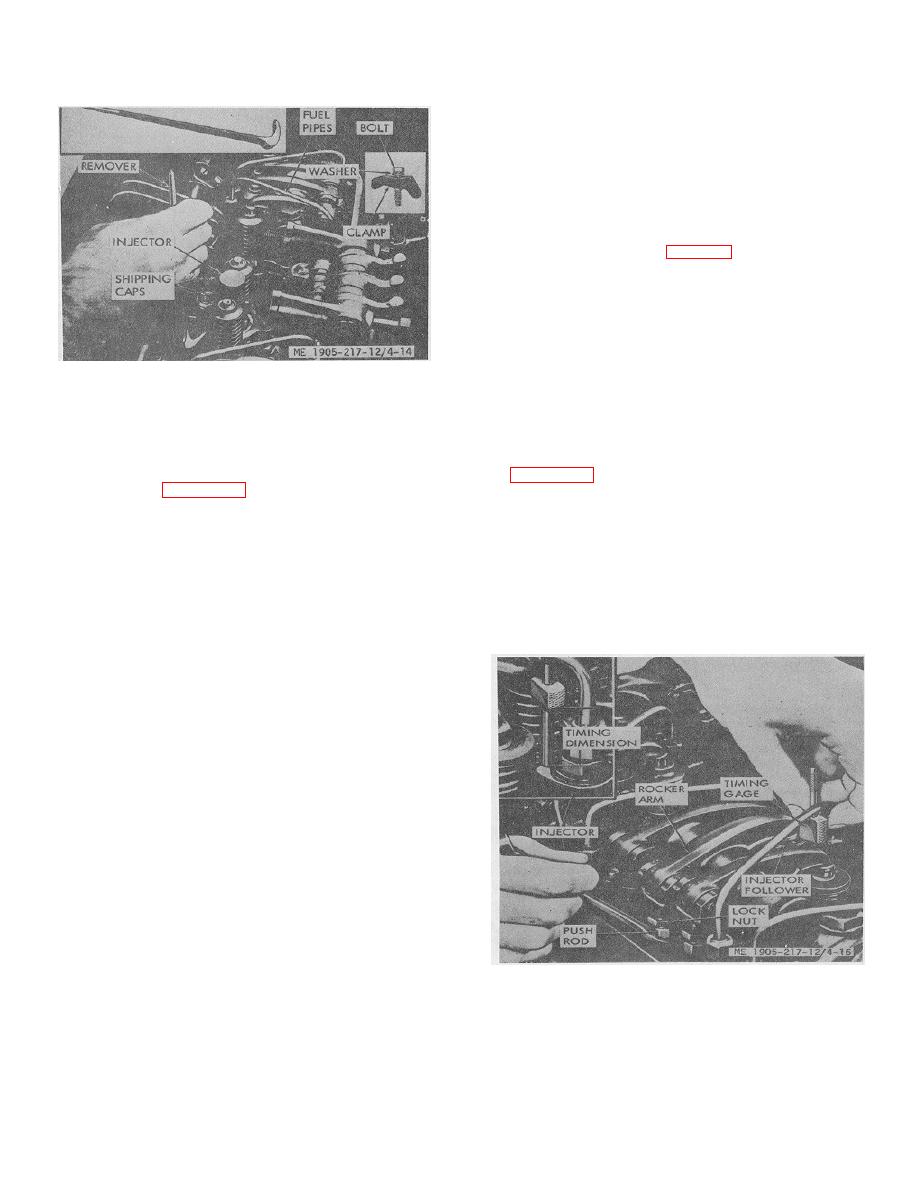

Timing the Injector (fig. 4-16).

(1) Pull the engine stop control out to the NO-

FUEL position.

(2) Rotate the crankshaft until the exhaust

valves are fully depressed on the cylinder to be timed.

Figure 4-14. Removing injector from cylinder head.

(3) Place the small end of the injector timing

injector and prevent any undue stresses from being

gage J1853 (for HV7 injector) in the hole [provided in the

exerted against the spray tip.

top of the injector body, with the flat of the gage toward

the injector follower.

d. Installation.

See figure 4-16.

(1) Refer to figure 4-13 and insert the injector into

the injector tube with the dowel registering with the

(4)

Loosen the push rod locknut.

locating hole in the cylinder head.

(5) Turn the push rod and adjust the injector

(2) Slide the rack control lever over so that it

rocker arm until the extended part of the gage will just

registers with the injector rack.

pass over the top of the injector follower.

(3) Place the injector clamp in place and install the

(6) Hold the push rod and tighten the locknut.

special washer. Install the bolt and tighten it to 20-25 ft-lb

Check the adjustment and, if necessary, readjust the

torque. Make sure that the lamp does not interfere with

pushrod.

the exhaust valve or injector springs.

NOTE

Check the injector control rack for free movement.

Excess torque can cause the control rack to stick or

bind.

(4) Move the rocker arm assembly into position and

tighten the rocker arm bracket bolts to 90-100 ft-lb

torque.

(5) Remove the shipping caps. Then, install the fuel

pipes and connect them to the injectors and the fuel

connectors. Tighten the connections to 12-15 ft-lb torque.

CAUTION

Do not bend the fuel pipes and do not exceed

the specified torque. Excessive tightening

will twist or fracture the flared end of the fuel

line and result in leaks. Lubricating oil diluted

Figure 4-16. Timing fuel injector.

by fuel oil can cause serious damage to the

engine bearings.

4-21

|

||

|

||