| Tweet |

Custom Search

|

|

|

||

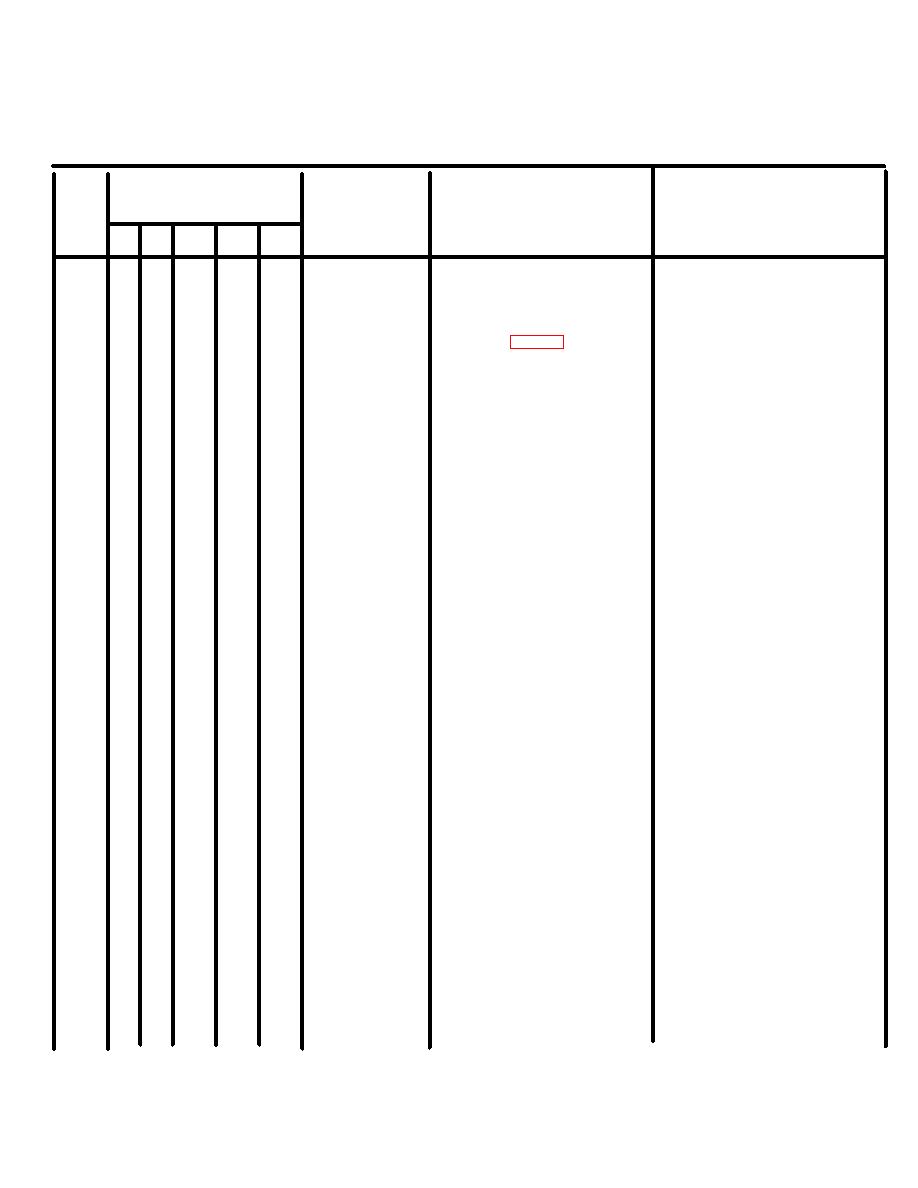

TM 55-1905-222-14

Operator Preventive Maintenance Checks and Services (Continued)

B-Before

A-After

M-Monthly

D-During

W-Weekly

Equipment is Not

PROCEDURES

INTERVAL

Item To Be

ITEM

Ready/Available If:

Check for and have repaired

Inspected

NO.

or adjusted as necessary

B

D

A

W

M

Inspect bracket for secure

mounting Inspect bowl for

cracks or defects Tighten

leaky connections and/or re-

place filter (para 3-17) as nec-

essary

Engine

Cooling

System

49

Piping

Inspect pipe joints and hose

connections for cracks or leaks

tighten hose clamps or replace

hoses as necessary

Check Keel Cooler hose con-

nection to ensure that hose Is

not long. Tighten as needed

Radios

Follow the procedure as out-

lined in the operators manual.

Life Jackets

Ensure that all ties and straps

are serviceable and that there

are no ripe or tears In the jack-

ets.

Life Rings

Ensure that the ring is in good

shape and that light works on

the ring.

Fire

Ensure that pins are in place

Extinguisher

and that extinguishers are

weighed and label with the

weight

Compass

Ensure that the compass is

reading correct readings Check

that there is no system error

showing on the display.

Cutlass

Listen for any unusual noises

Bearing

during operations at all RPM

ranges

Emergency

Remove plug and ensure that

Steering

the tiller arm turns from 35 de-

grees right and 35 degrees left

rudder

2-34 Change 6

|

||

|

||