| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

NOTE

It may be necessary to bring the crankshaft end clearance to specifications by

installing oversize bearings. In extreme cases, a new or reconditioned

crankshaft must be used.

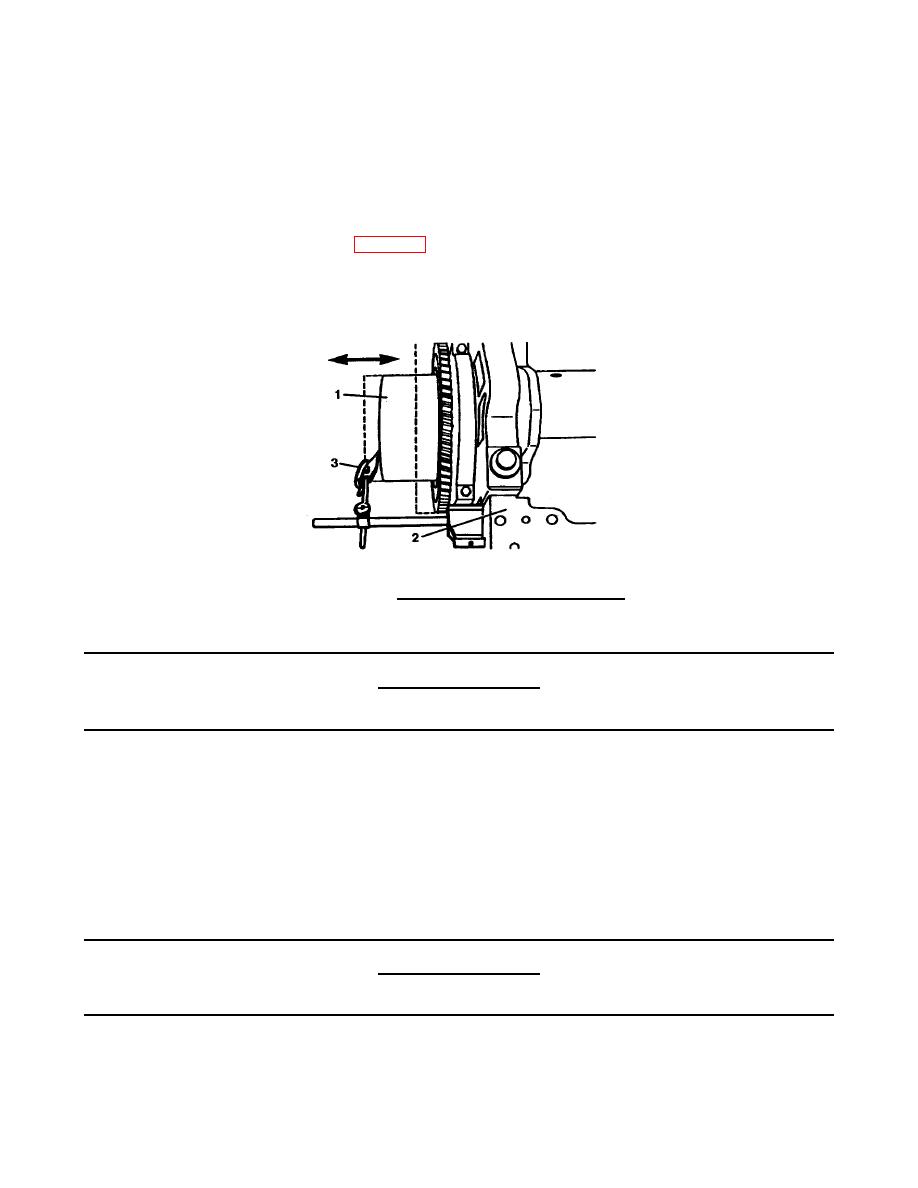

o. Attach a dial indicator gauge (3, FIG. 4-61) to the cylinder block (2) with the contact point of the

gauge resting on the crankshaft flange end-face. Measure end clearance. If end clearance is not

between 0.005 inch (0.13 mm) and 0.020 inch (0.51 mm), c eck for foreign matter on thrust bearings

h

and crankshaft flange.

FIGURE 4-61. Crankshaft End Clearance Check.

Table 4-5. Main Bearing Capscrew Tightening

Capscrew Torque Value

N

m

Step

ft-lb

175

1

130

285

2

210

610

3

450

Loosen

4

Loosen

175

5

130

285

6

210

610

7

450

Table 4-6. Main Bearing Cap Side Bolt Tightening

Capscrew Torque Value

N

m

Step

ft-lb

65

1

50

215

2

160

455

3

335

4-55

|

||

|

||