| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

Table 2-2. Troubleshooting-CONT

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

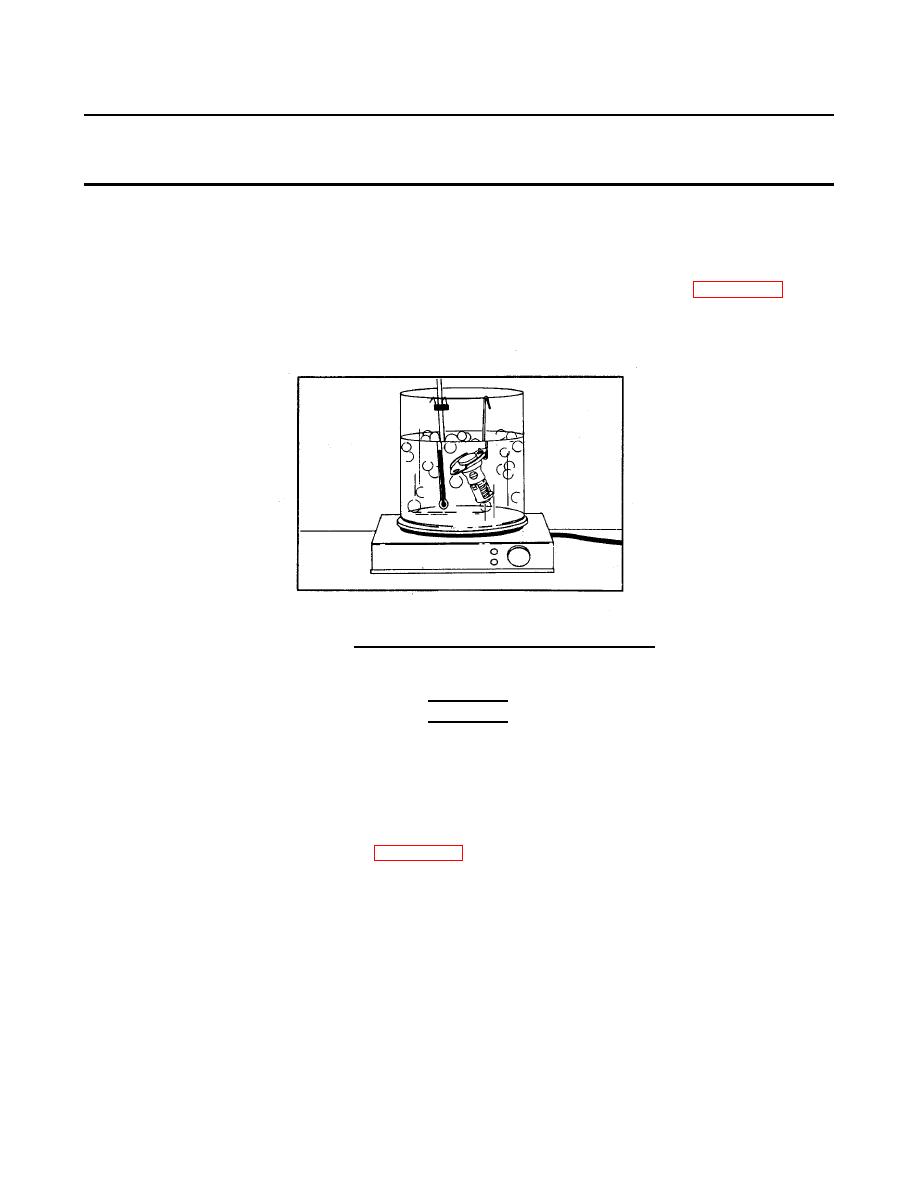

b. Suspend the valve and a 240 (115 ) thermometer in a container of new lubricating oil. Do not

F

C

allow the valve or the thermometer to touch the sides of the container.

c. Heat the lubricating oil.

d. Note the temperature at which the valve is fully extended. The valve must be fully extended to at

least 2.770 inches (70.36 mm) when the temperature reaches 234 (112 ) (FIGURE 2-2).

F

C

e. Replace the valve if it does not operate as described.

FIGURE 2-2. Oil Cooler Bypass Valve Temperature Check .

STEP 4. Check for defective oil filter/cooler.

WARNING

Carefully cut the lubricating oil filter open. The filter element spring is under

compression and can cause personal injury.

.

a. Cut the top off the oil filter, remove the-filter element, and inspect the filter element for evidence

of moisture or metal particles (FIGURE 2-3). '

2-31

|

||

|

||