| Tweet |

Custom Search

|

|

|

||

(a) Insert front end of camshaft into the

11 ounces, the idler gear and bearing assembly are

opening on blower side of the engine block. Push the

satisfactory for use

camshaft into block until cam gear teeth almost engage the

10. Remove spring scale, cord and

teeth of the idler gear. Use care, and avoid damage to the

stick. Remove steel plate from face of gear.

cams.

(5) Installation.

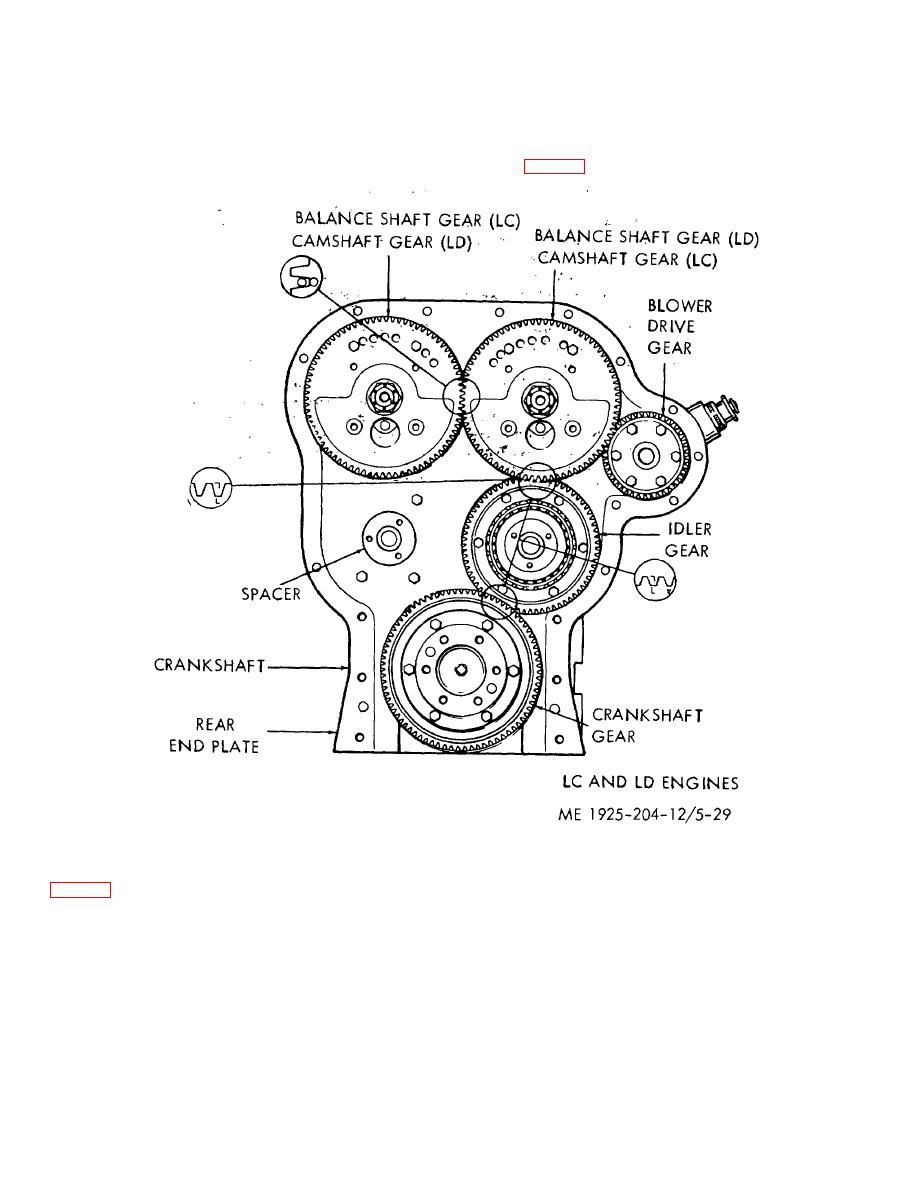

(b) Align the timing marks on the mating

gears (fig. 5-29), then slide the camshaft gear into place..

Figure 5-29. Gear train and timing marks. L. H. rotation.

(c) Secure the camshaft rear bearing (17,

(f) Install the front end cam and balance

and capscrews (4). The camshaft gear may be turned to

shaft bearings. Do not hammer bearings into cylinder block,

accommodate the capscrews through the holes in the gear

or the thrust washers may be dislodged. Secure the bearings

web. Tighten the capscrews to a torque of 35-40 ft. lbs.

with lockwashers (5) and capscrews (4). Tighten to a torque

(d) Install the balance shaft in a similar

of 35-40 ft. lbs.

manner.

(g) Apply grease to the steel face of the

(e) Apply grease to the steel face of each

remaining thrust washers (6 and 27) and install them so that

thrust washer (6 and 27). Then place one against the thrust

the steel faces are against the front end bearings (3 and 26).

shoulder (31) of each shaft, making sure the steel face is

(h) Turn

the

camshaft

intermediate

toward the front end bearings.

bearings until the holes in the bearings line up with the

5-34

|

||

|

||