| Tweet |

Custom Search

|

|

|

||

TM 5-2805-261-13

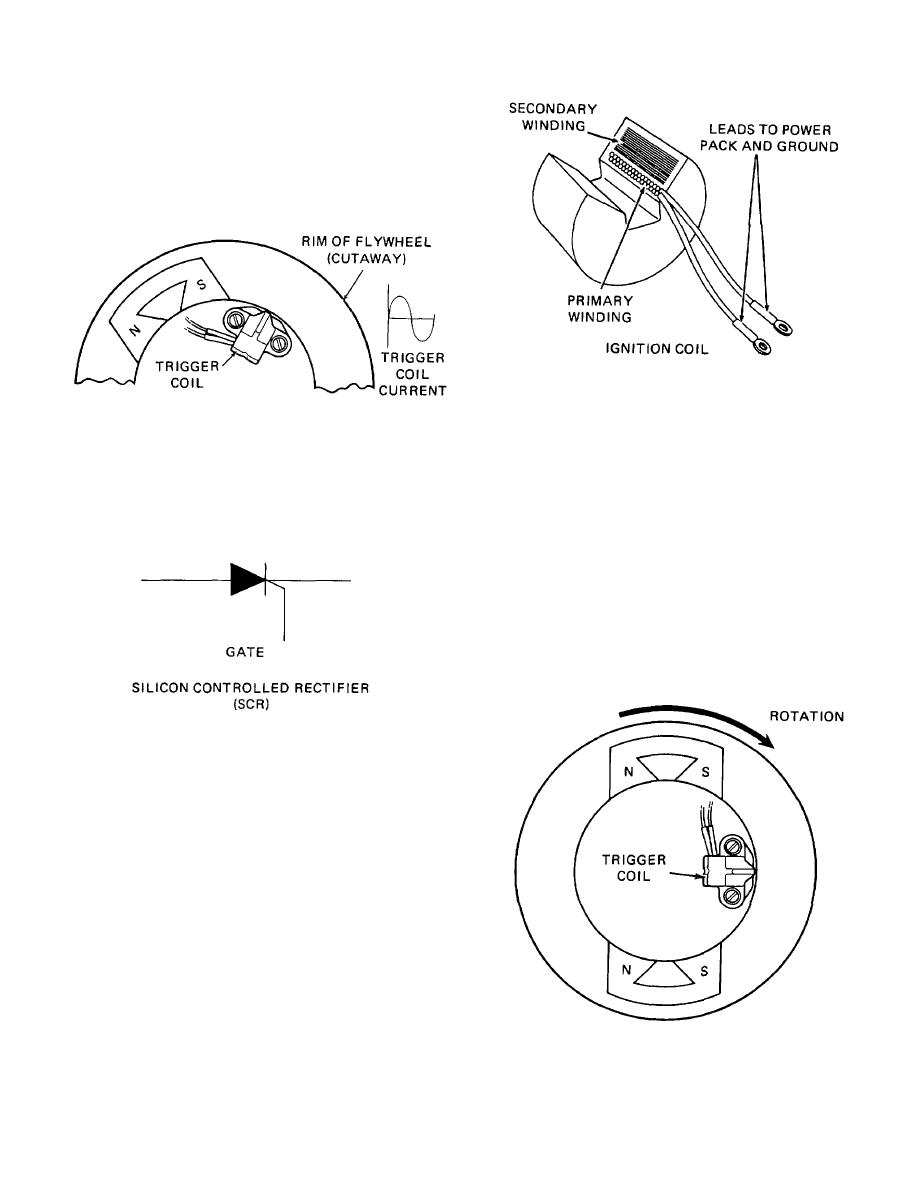

The trigger coil is located on the armature plate opposite the

charge coil. (Diagram D) It has only one point of close

proximity to the spinning magnets (the charge coil had three).

When a magnet passes this coil, an electric current is

generated but not repeated three times as with the charge

coil. This current or "trigger pulse" is also routed by wires to

the power pack.

Figure 1-16. Diagram F

The capacitor charge flows through the primary winding and

Figure 1-14. Diagram D

sets up a magnetic field in the core of the ignition coil. When

the charge has dissipated, the magnetic field in the core

Another electronic device inside the power pack, called an

breaks down. As it does so, the magnetic field passes

SCR, receives the trigger pulse. (Diagram E) An SCR is an

through the secondary windings setting up a current in them.

electronic switch. When the trigger pulse is applied to its

Since the secondary coil has many turns of wire for the field to

"gate," the SCR allows the charge, which has been stored in

pass through, the voltage established is very high.

the capacitor, to pass out of the power pack.

The high tension lead from the ignition coil carries this high

voltage current to the spark plug where it jumps the spark gap

and ignites the fuel/air mixture in the cylinder.

Since this 40-horsepower outboard has two cylinders, it must

have two spark plugs and also has two ignition coils. The

charge for the capacitor must be routed to the proper coil at

the proper time. This timing decision is made by magnetic

polarity.

Figure 1-15. Diagram E

Once the SCR has been "turned on," the capacitor releases its

charge very rapidly. This charge-discharge process can be

compared to that of a spring. A spring may be compressed

slowly, but when released, its energy is expended almost

instantly.

The burst of electrical energy from the capacitor is routed

through wires from the power pack to an ignition coil.

Ignition coils are a form of electrical transformer. (See

Diagram F) They consist of a primary winding and a

secondary winding encapsulated around an iron-laminated

core. The primary winding consists of a few turns of heavy

gage wire and the secondary winding has many turns of fine

gage wire.

Figure 1-17. Diagram G

1-9

|

||

|

||