| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

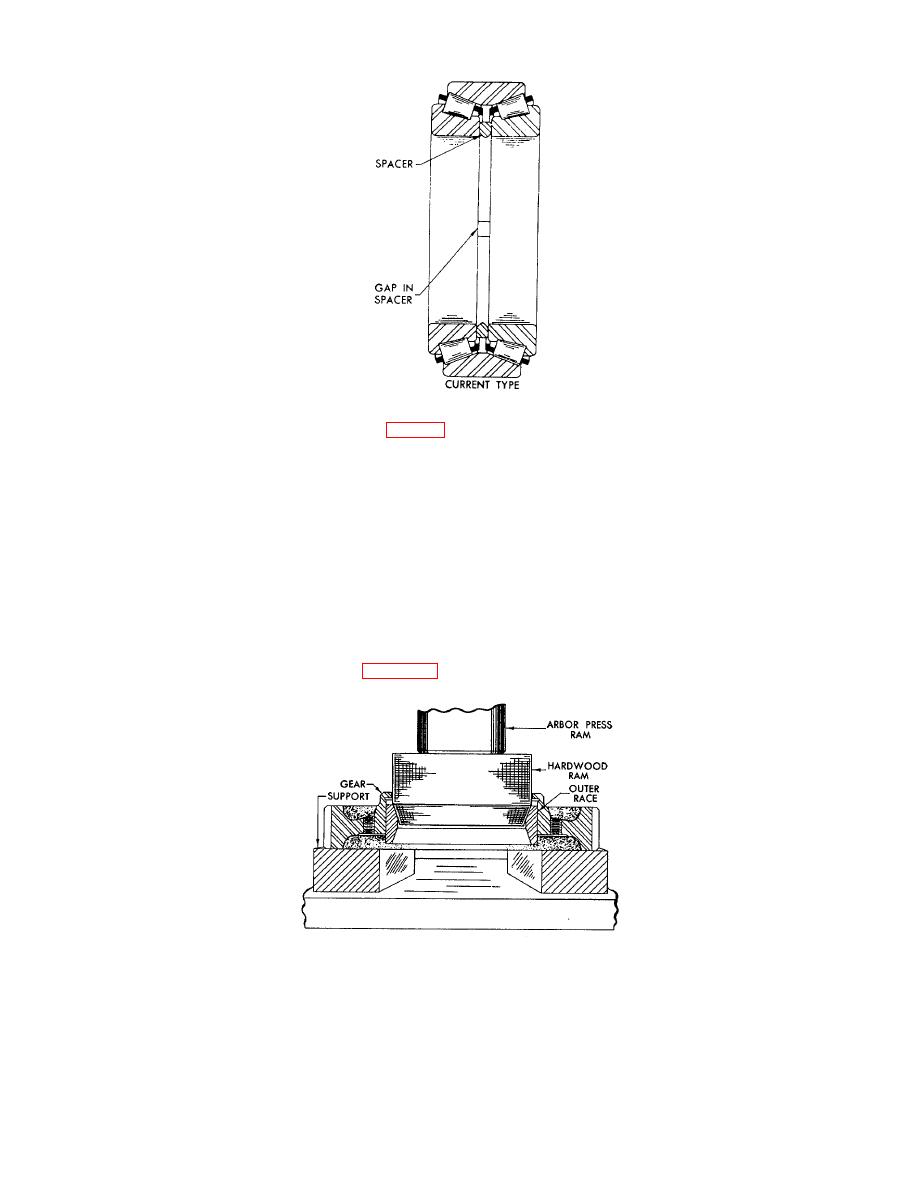

Figure 3-61. Idler gear bearing and spacer, cross-section view.

(a) After pressing out the idler gear hub, (fig. 3-59), place the gear assembly on a clean work surface with the rear

face of the gear toward the work surface.

(b) Position the inner races until the notches in the bearing cones are approximately 180 from the gap of the

spacer.

(c) Press against the spacer and gently rock the gear to release the spacer from the grooves in the bearing cones.

The tang of a small file, or a similar tool, may be used for this operation. Ordinarily, the spacer will remain with one of the

two bearing cones.

CAUTION

Exercise care to prevent the rollers escaping their cage and scattering. If this

should occur, the bearing SHOULD NOT be reassembled and reused since the rollers

were selectively mated to the bearing races when originally manufactured. A new

bearing assembly must be used.

(d) Lift the gear, bearing outer race, top inner race and its rollers away from the bottom inner race and the rollers.

(e) Hold the top inner race and the rollers against the outer race, turn the gear over, and place it on work surface.

Then lift the gear away from the inner race and the rollers.

(f) Make a hardwood ram as shown in figure 3-62. Then position the idler gear in the arbor press and with the gear

suitably supported, press the outer race from the gear.

Figure 3-62. Hardwood ram for pressing outer race from gear.

3-84

|

||

|

||