| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

ME 1905-217-34/5-4

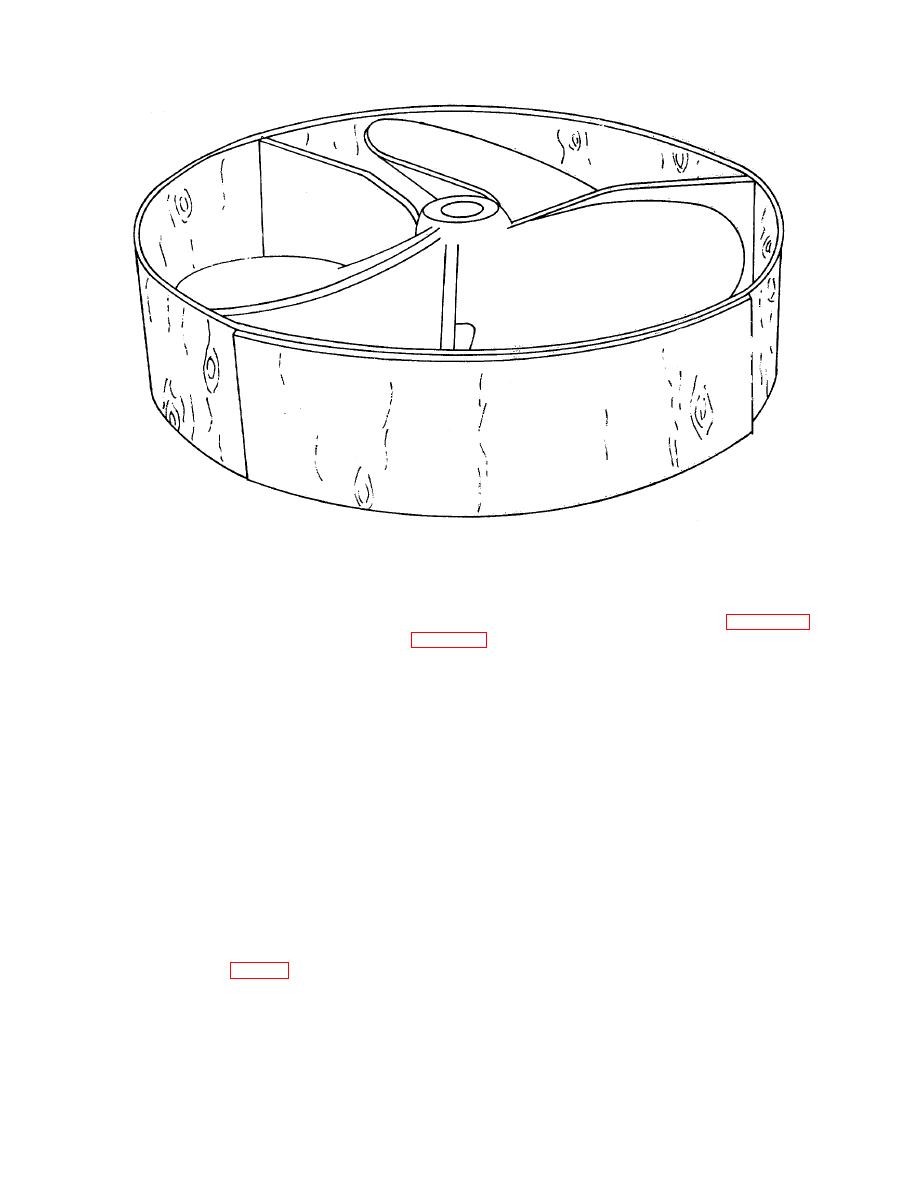

Figure 5-4. Propeller on pitch block after straightening.

notches. Normally notches of the size shown in figure 5-4 are not filled if other vessels are deadlined for repair.

Damaged edge repair is covered in paragraph (8) (b), below.

(6) Repairs by Welding. The location of the repair governs the kind of weld used and the care

necessary. Root sections of the blade carry more stress than sections near the tip and therefore are critical.

All metal deposits above the surface of the blade will have to be removed.

(7) Repair of Root Sections. Because of the high stresses on the blade between the hub and 0.4 radius,

any repair in this area is considered major repair, and a welding procedure that can be depended upon to

produce a strong, sound weld substantially free of residual stresses should be used. Metallic arc welding,

multiplelayer gas welding, and the hot-flow process are approved methods for root section repair.

(8) Repair of Sections Outside the 0.4 Radius. Repairs in these areas are relatively minor and can be

accomplished with the use of multiple-layer gas welding or metallic arc welding.

NOTE

The use of silver brazing alloy or any other low temperature brazing alloy is not an

action of high velocity water.

from a dis-propeller (fig. 5-5). Cracks are ground or cut open and then welded together. The entire crack must

be ground out or it will start cracking again. If necessary, blades can be built up with the same welding rods

used in the process of welding. Small notches in the edges are sometimes filled by welding.

5-4

|

||

|

||