| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

NOTE

The upper main bearing shells are grooved and drilled for lubrication. No. 1 and

9 are 1/8 inch (3.17 mm) narrower than Nos. 2 through 8; locate them

accordingly.

c.

Lubricate the crankshaft journals and upper main bearing shells with a coat of clean engine lubricating

oil.

WARNING

The crankshaft is heavy. To avoid personal injury or equipment damage, use a

lifting sling or get assistance when lifting the crankshaft.

CAUTION

Do not cock the crankshaft during installation; damage to the bearing shells may

result. If the crankshaft cocks, remove it and inspect the condition and location of

the bearing shell and the condition of the thrust flange face.

d. Use a suitable hoist and lifting device to carefully lower the crankshaft into position (FIG. 4-50).

Ensure the end of the crankshaft with the gear that has the smallest diameter points toward the front of

the block.

CAUTION

The grooves in the thrust bearings must point toward the flange on the crankshaft

or the engine will be damaged.

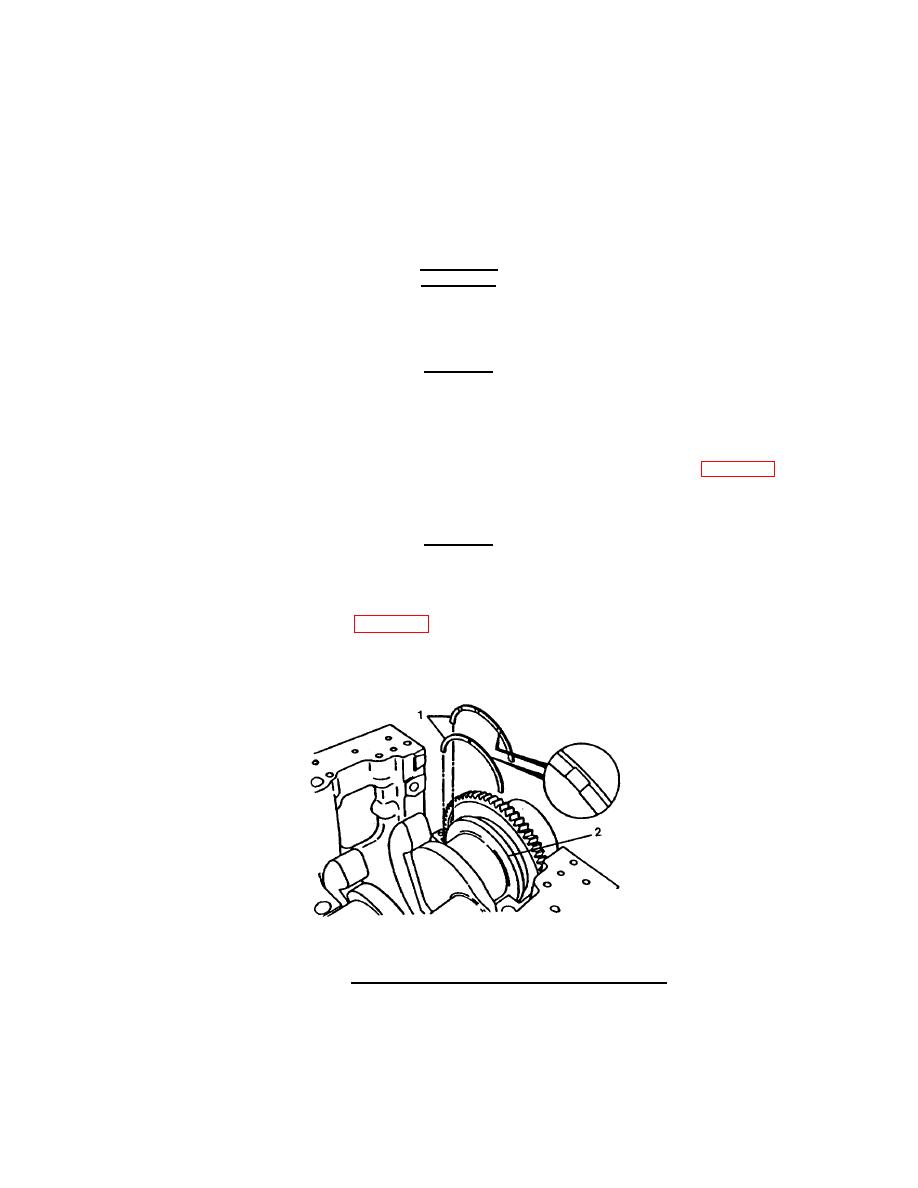

e. Lubricate the thrust bearings (1, FIG. 4-57); position with the grooved side of the face toward the

crankshaft thrust flange (2) one on either side of flange and slide them into place in the thrust bearing

retainer.

FIGURE 4-57. Crankshaft Thrust Bearing Removal/Installation.

4-51

|

||

|

||