| Tweet |

Custom Search

|

|

|

||

TM 55-1925-204-12

(b) Remove capscrews (35) and adapter

(2)

Removal.

(36), arm (6) and shaft (3).

(a) Remove capscrews securing header

(c) Remove nut from shaft (17), cam (18)

connections at cylinders and receiver, then remove header from

and sleeve (19).

the receiver, and connector (5, fig. 47) from line by uncoupling

flanges.

(d) Remove capscrews securing cover (25)

then remove cover (25) from gear (26). Remove gasket (24).

(b) Remove and discard gaskets (3 and 4).

(3) Cleaning, Inspection, and Repair.

(c) When necessary, remove covers from

housing then remove and discard gaskets (1 and 2).

(a) Clean all parts in clean fuel oil and blow

dry with ships service air.

(3) Cleaning, Inspection, and Repair.

(b) Inspect forward cam (18) and the reverse

(a) Wash all parts in clean fuel oil then wipe

cam attached for wear or rough lobes. Examine movement of

dry.

shaft (17). If there is end play in shaft, remove capscrews

(b) Be sure that all gasket material is

securing sleeve (29) and remove a shim (50) and a shim (31).

removed from surfaces to be gasketed.

Replace and secure sleeve (29), then try shaft end play.

(c) Inspect header sections for dirt, or

Removal of shims should have reduced end play by allowing

moisture residue.

bracket (30) to cause reversing mechanism to meet spool (33)

(4) Installation.

earlier, therefore reduce end play.

(a) Replace new gaskets (1 and 2), if

(c) If forward cam (18) or reverse cam

removed, then install covers.

attached is defective, separate the cams. Replace the defective

(b) Replace new gaskets (3) under header

cam (s).

sections at the receiver and tighten capscrews securing header

(4) Reassembly. Assemble the air distributor by

sections. Install new gaskets (4) at flanges of connector (5),

reversing the procedure in step (2) (a) through (d) above.

then bolt to header sections at both ends of connector.

(5) Installation.

Install

by

reversing

the

e. Air Receiver (BOX). The air receiver distributes air

procedures in step (1) (a) and (b) above.

from the scavenging pump to cylinders under the proper

d.

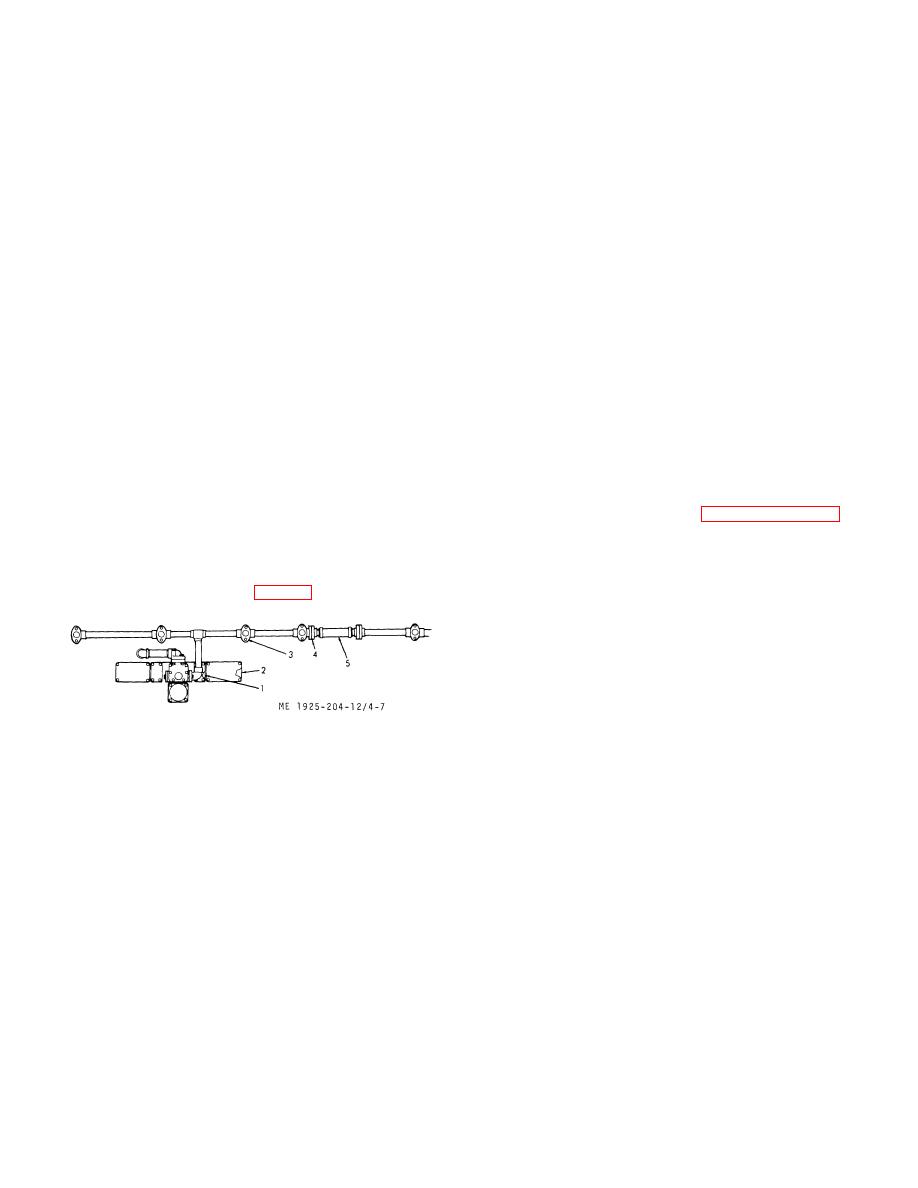

Air Start Header. The air start header is the piping

pressure (from 1 1/2 to 2 1/2 psi) for forcing exhaust gases out,

arrangement of air to cylinders for starting (reversing) the

and filling cylinder with combustion air.

engine. The principal maintenance requirement is to stop

leakage of air from header. When an air leak is suspected, test

remove the air receiver sections.

and correct.

(2) Cleaning, Inspection, and Repair.

(1) Testing. If a leak can not be felt by the fingers

(a) Wash the receiver parts in clean fuel oil

at joints, make up a solution of soap and water and apply at all

and wipe dry.

gasketed connections of header (fig. 4-7) at cylinders.

(b) Clean all gasket surfaces. Be sure that

all particles are removed, and the machined surfaces are

smooth.

(c) Inspect receiver for cracks, or other

damage. Replace a defective receiver section, or cover.

1. Gasket, housing cover

4. Gasket, pipe flange

2. Gasket, housing cover

5. Connector, air start header,

3. Gasket, receiver to header

flexible, with flanges

Figure 4-7. Air start header

4-15

|

||

|

||