| Tweet |

Custom Search

|

|

|

||

(1) Secure the steering system and tag al

(3) Check the time it takes for rudder to

travel the 90 by using a stop watch. If the time of

switches to prevent operation of power unit while

working on the ram.

travel is greater than 12 seconds, notify general support

maintenance.

(2) Open the valve (13, fig. 5-122) to

prevent pressure being inadvertently applied to the

c.

Hydraulic Ram Packing and Grie Fitting

hydraulic ram.

Replacement.

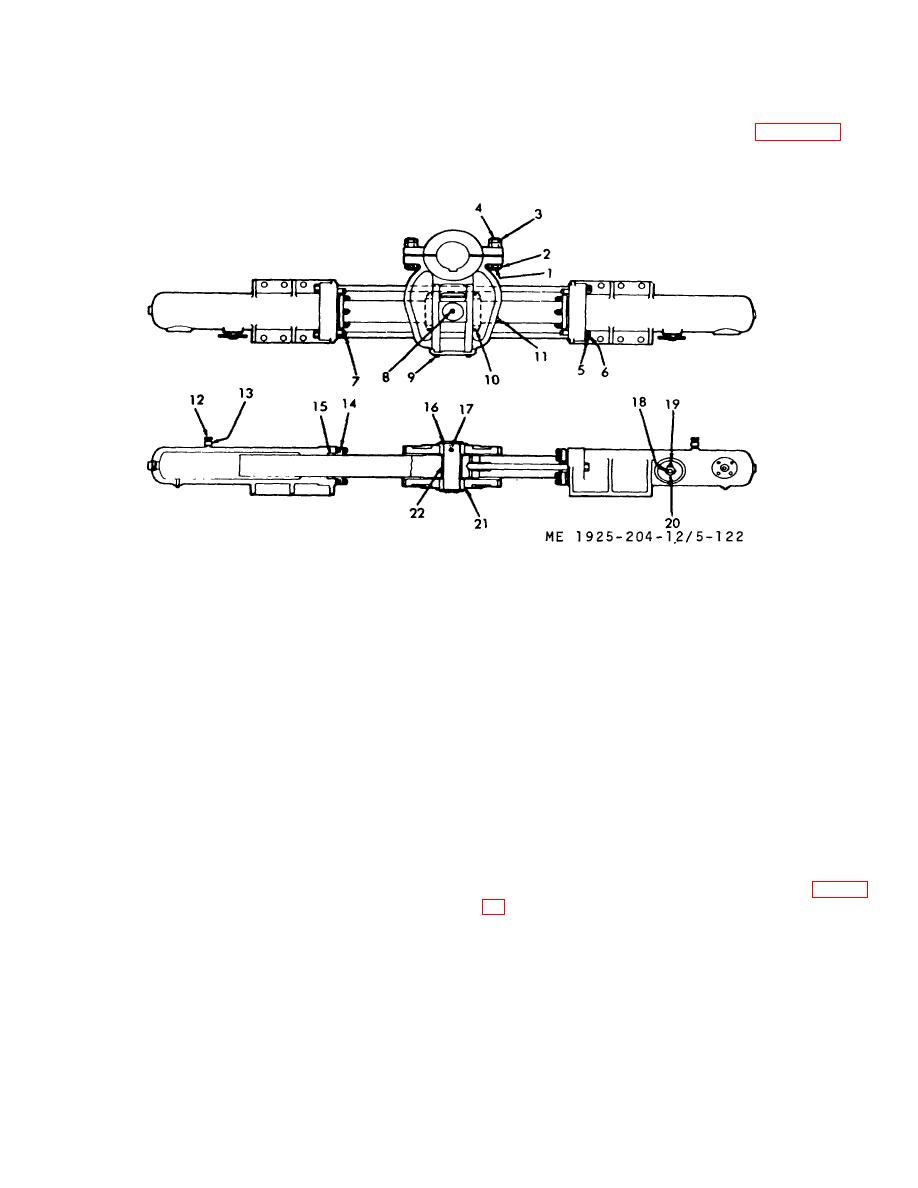

12.

Valve, plug

1.

Cotterpin(4)

13.

Valve, aircylinder

2.

Nut (8

14.

Retainer, packing

3.

Nut (4)

15.

Preformed packing

4.

Stud (4)

16.

Pin, tiller shoe

5.

Cotterpin 14)

17.

Lubrication fitting

6.

Nut (4)

18.

Cotterpin (2)

7.

Capscrew (8)

19.

Lubrication fitting (2)

8.

Lubrication fitting (2)

20.

Bearing, sleeve

9.

Capscrew(4)

21.

Shoe, tiller

10.

Capscrew (12)

22.

Bearing, sleeve

11.

Lubrication fitting

Figure 5-122. Hydraulic ram assembly.

(3) Remove nuts and lockwashers securing

handtight. Be sure retainer is square with cylinder end.

the packing retainer (14) then move retainer away from

(8) Repeat steps (2) through (7) above on

cylinder.

the opposite ram.

(4) Use a packing hook to remove old

(9) After both rams have been repacked,

packing from end of cylinder.

close valve (13), then start the steering system (para 2-

(5) Install preformed packing (15) with small

diameter of rings pointing away from the cylinder, then

(10) Use the power steering unit to operate

use retainer to move packing into cylinder.

the rudder. Observe packing being checked-i.e., if

(6) Install a second preformed packing (15)

rudder is turning right, pressure is being applied to right

with small diameter of rings away from the cylinder, and

ram. Tighten nuts around retainer evenly until all

use the retainer to move packing into cylinder.

leaking stops.

(7) Position retainer (14) against packing,

(11) Vent the system, then repeat

install lockwashers and nuts, then tighten nuts

procedures of (10) above.

Continue venting and

tightening

5-176

|

||

|

||