| Tweet |

Custom Search

|

|

|

||

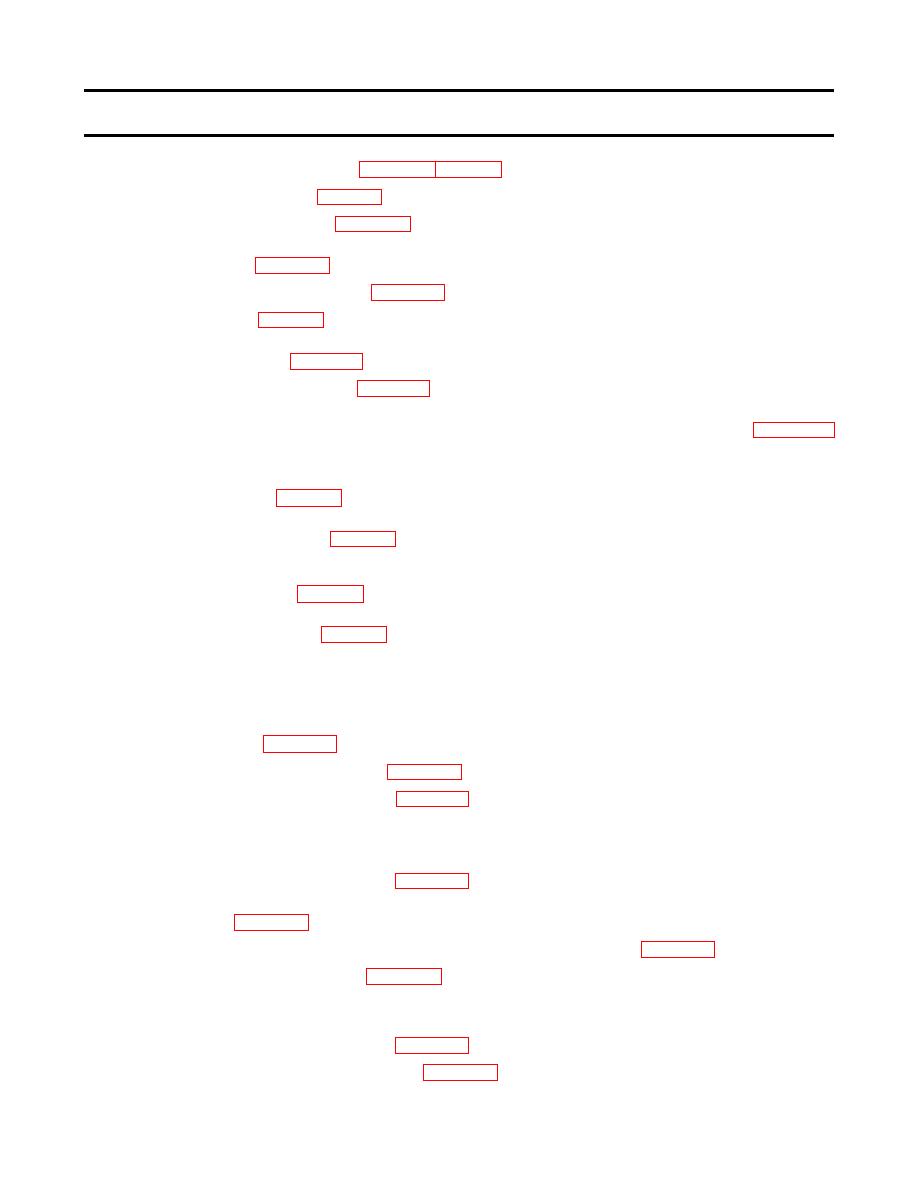

TM 55-1905-217-34

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. Excessive crankcase pressure

Step 1. Check for cylinder blowby.

Replace rings, piston or liner (paras 3-20 and 3-21).

Step 2. Check for leakage at blower gasket.

Replace blower gasket (para 3-9).

Step 3. See if cylinder block end plate gasket is leaking.

Replace end plate gasket (para 3-30).

7. High oil consumption

Step 1. Check for worn oil control rings.

Replace rings (para 3-20).

Step 2. Check for scarred liners, rings or pistons.

Replace rings, pistons or liners (para 3-20).

Step 3. Check blower oil seal for leaks.

Repair blower (para 3-9).

8. Low oil pressure.

Step 1. Check oil pump.

Overhaul oil pump (para 3-19).

Step 2. Check oil pressure regulator.

Repair oil pressure regulator (para 3-19).

9. Incompletely burned fuel (black exhaust smoke).

Step 1. Check for obstruction in exhaust piping, TM 55-1905-217-12 (para 4-40).

Disassembly exhaust system components, repair or replace parts. (TM 55-1905-217-12, paras 4-22,

4-40).

Step 2. Check for faulty blower.

Clean liner parts; remove obstruction to blower screen. (para 4-37 of TM 55-1905-217-12).

Step 3. Check for clogged blower screen or dirty cylinder liner parts.

Overhaul blower (para 3-9).

10. High engine coolant temperatures.

Step 1. Check for faulty fresh water pump.

Repair fresh water pump (para 3-6).

Step 2. Check for obstructed fresh water cooling system.

Disassemble, clean and reassemble component parts of fresh water cooling system.

Step 3. Check for damaged keel cooler.

Replace keel cooler (para 3-8).

11. High muffler temperatures

Step 1. Check for faulty raw water pump.

Repair raw water pump (para 3-7).

Step 2. Check for obstructed raw water cooling system.

Disassemble raw water (muffler) cooling system, clean, and reassemble, Refer to TM 55-1905-217-

12, (para 4-40).

Step 3. Check for damaged muffler.

Replace muffler (TM 55-1905-217-12, para 4-40).

12. Malfunction of power take-off assembly (ramp hoist pump drive).

Step 1 Check for worn clutch.

Replace clutch (para 3-12).

Step 2. Check clutch release mechanism.

Repair clutch release mechanism (para 3-12).

Step 3. Check for broken drive or other internal damage.

Overhaul power take-off assembly (para 3-12).

Transmission and Transfer Gear

1. Gear inoperative (Drive shaft does not rotate) Condition A-Selector valve in forward position.

Step 1. Check for low oil pressure.

Refer to 2. Low oil pressure below.

Step 2. Check for worn forward clutch facings.

Replace if found excessively worn (para 3-26).

Step 3. Check for improper dump valve operation.

Check the dump valves for varnish or other foreign material that would cause poor seating or restrict

movement (para 3-26).

Step 4. Inspect the clutch plate for damage.

Clutch plate may be sheared or loose on the hub and require replacing (para 3-26).

Replace damaged parts found (para 3-26).

Condition B-Selector valve in reverse position.

Step 1. Check for low oil pressure.

Refer to 2. Low oil pressure below.

Step 2. Inspect the clutch facings.

Replace if found excessively worn (para 3-26).

Step 3. Check for damaged planetary assembly.

Disassemble and repair with new parts (para 3-26).

2-4

|

||

|

||