| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

ficienies and shortcomings will be recorded together with

4-12. Preventive Maintenance Checks and Services

the corrective action taken on DA Form 2404 (Equipment

This paragraph contains a tabulated listing of preventive

Inspection and Maintenance Worksheet) at the earliest

maintenance checks and services. Refer to Table 4-2.

possible opportunity.

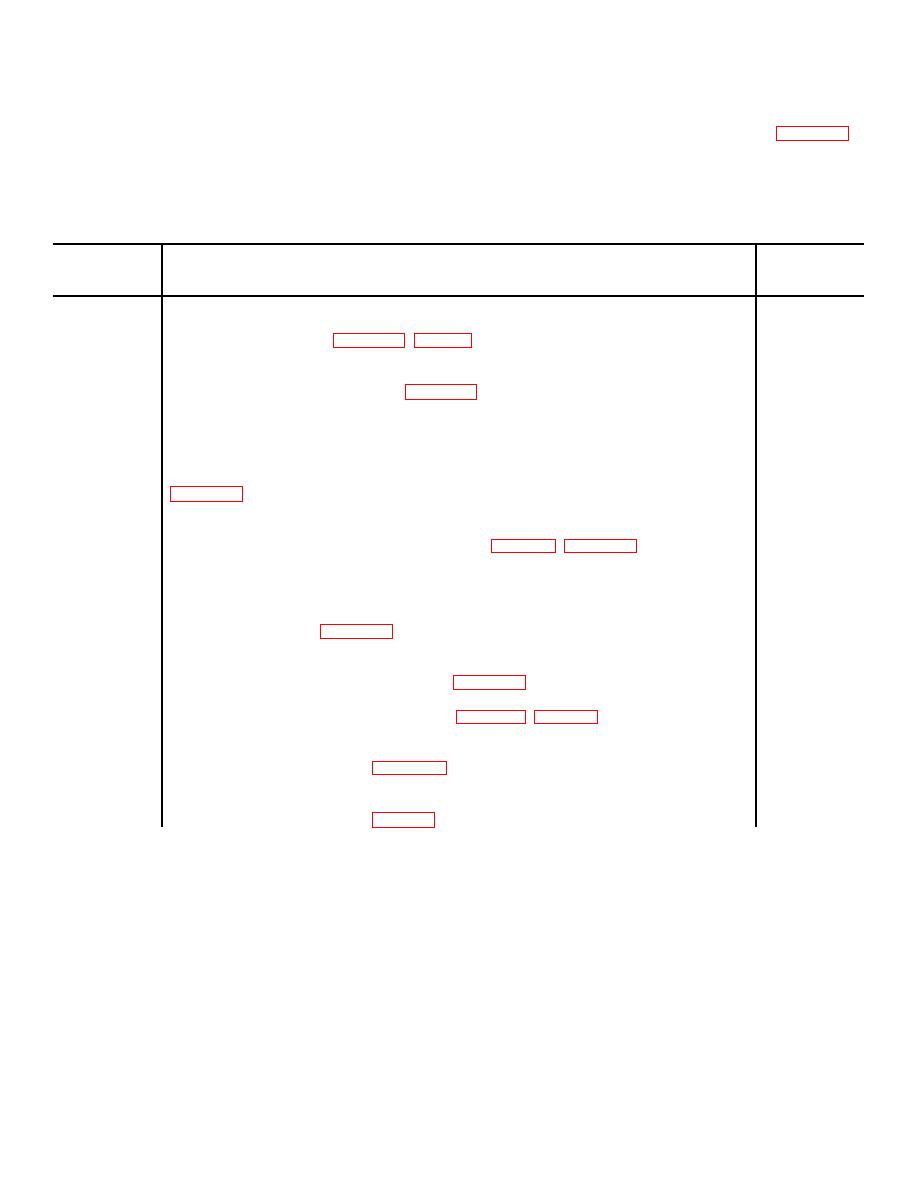

Table 4-2. Organizational Preventive Maintenance Checks and Services

Q - Quarterly

Total man-hours required: 10.1

Work

Sequence

ITEM TO BE INSPECTED

Time

Number

PROCEDURE

(M/H)

SECTION I - FUELS

1

FUEL FILTERS

Replace filter elements (para 3-10) (fig. 3-7).

0.2

SECTION II -- Steering

2

STEERING HYDRAULIC SYSTEM SUCTION SCREENS

Drain oil in tank and clean screens (para 4-77).

0.5

SECTION III - RAMP

3

RAMP HOIST SYSTEM SUCTION STRAINERS AND SCREENS

Service strainer on hull numbers 8500 thru 8519 when indicator is red. On hull num

bers 8520 thru 8560 and 8580 thru 8618, drain oil and clean screws every 200 hours

0.5

SECTION IV - Power Take-off

4

POWER TAKE-OFF CLUTCH, RAMP SYSTEM PUMPS

Check for proper operation, adjust if necessary (fig. 4-78) (para 4-88).

0.2

SECTION V - Engine

5

Clean brushes and brush holder Replace brushes if they extend less than 1/4 in.

0.9

beyond brush holder (para 4-48).

0.2

6

GOVERNOR

Inspect for loose, worn, or binding linkage. Check to see that governor is securely

0.1

mounted and in good operating condition (para 4-30).

7

FILTER--HYDRAULIC STARTING SYSTEM

Change filter element at 6-month interval (para 3-14) (fig. 4-51).

0.4

8

ENGINES

At 6-month intervals, check valve clearance and adjust if necessary. Perform com-

2.1

pression test on each engine (para 4-20, 4-21).

4.0

9

RAMP LOCKING MECHANISM, FOR HULL NUMBERS 8540 THRU 8660 AND

8680 THRU 8118.

Lubricate all fittings monthly (fig. 4-81).

1.0

SECTION VI. TROUBLESHOOTING

tions to take. You should perform the tests/inspections

4-13. General

and corrective actions in the order listed.

a. This section contains troubleshooting information

b. This manual cannot list all malfunctions that may

for locating and correcting most of the operating troubles

occur, nor all tests or inspections and corrective action.

which may develop in the LCM-8. Each malfunction for

If a malfunction is not listed or is not corrected by listed

an individual component, unit, or system is followed by a

corrective actions, notify higher authority.

list of tests or inspections which will help you to

determine the probable causes and corrective ac-

4-8

|

||

|

||