TM 5-1940-321-13&P

3-11. RELATED ITEMS NOT SUPPLIED. This section provides a functional description of some commonly

used related items that are available for the F530 IAB. These components are not provided with the standard

F530 IAB and must be ordered separately.

Provide adequate ventilation if CO2 is used to inflate the IBA. Death by suffocation

could occur.

that require rapid inflation following storage, delivery, or concealment in a rolled condition. After CO2 system is

properly installed in the craft, inflation is initiated ny opening a valve. The main and lower buoyancy tubes will

become completely inflated in approximately three minutes at an ambient temperature of 70 F. The keel must be

inflated with the foot pump.

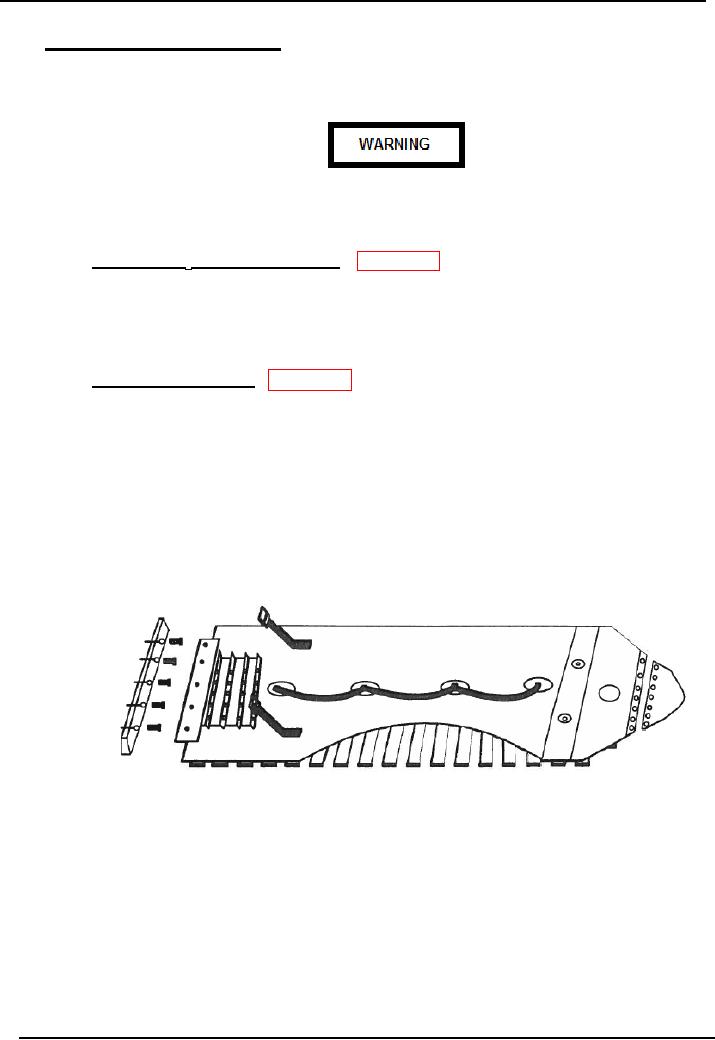

b. Roll Up Flooring System. (Figure 3-17). This system consists of six parts: the aluminum slats, the

floor covering fabric, transom straps with buckles, and the floor rope. The flooring consists of internal aluminum

alloy slats that are sandwiched between two pieces of coated fabric. This provides wear protection and allows the

flooring to be rolled for storage and unrolled during inflation. It enables the deflated, rolled up craft to be quickly

inflated with floor in place when using a CO2 filled cylinders. The Rigid Flooring System can be replaced with a

Semi-Rigid Flooring System. The retaining batten secures the flooring in place when fastened to its predrilled

points on the transom. The cylinder stowage sheaths secure the two CO2 inflation bottles in place by lacing. To

complete installation, the transom floor straps attach to the mating male sections installed on the transom. The

nylon floor rope is woven through D-rings (equipment tie-downs). The F-rings accept lines for securing equipment

or cargo to the flooring.

Figure 3-17. Semi-Rigid Flooring System.

3-16