TM 5-1940-321-13&P

SCHEDULED MAINTENANCE

Section I. INTRODUCTION

5-1 . INTRODUCTION. This chapter contains maintenance procedures and performance tests to be

performed on a scheduled basis. The IAB must be kept in operational condition at all times. Follow the

procedures in this chapter to maintain the craft in operational condition and extend its service life by controlling

the deterioration of its components. Scheduled maintenance prevents components of the IAB from becoming

unserviceable. Appendix H contains Limited Technical Inspection Form.

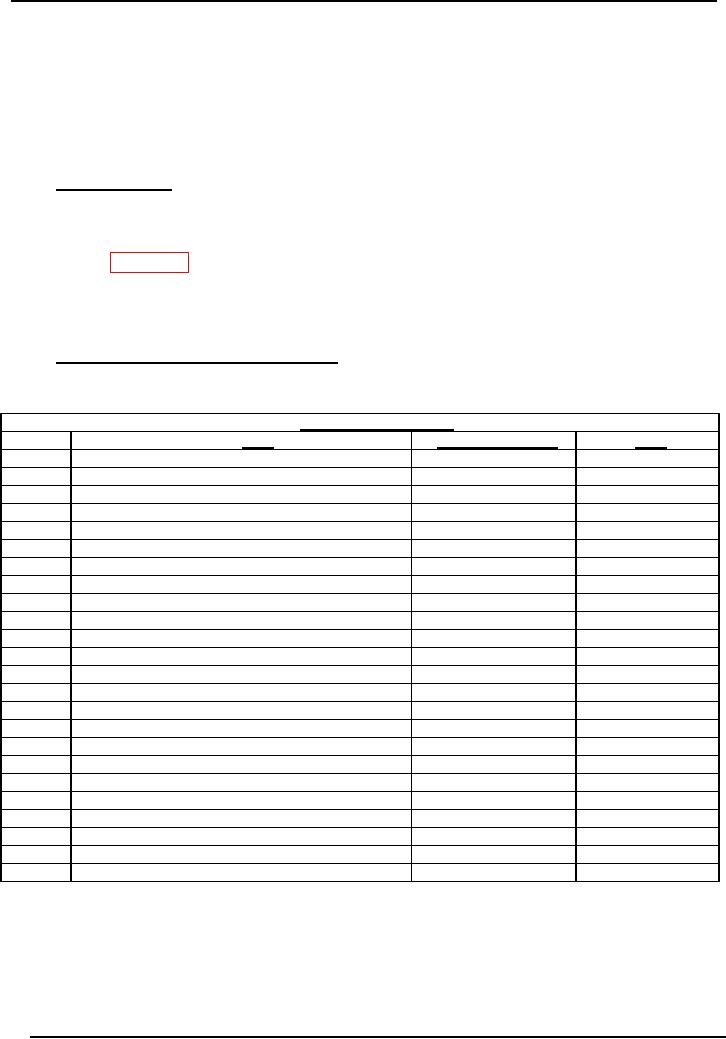

Section II. TOOLS AND EQUIPMENT

5-2. TOOLS, EQUIPMENT, AND MATERIALS. Tools, equipment, and materials, including consumable

items required for scheduled maintenance, are listed below.

Tools and Equipment

Item

P/N Cage Code

NSN

A

Go/No Go Pressure Gauge

1008-60042

B

Screwdriver, Flat-tip

5120-00-278-1267

C

I/C Valve Calibration Tool

7029-60042

D

Half- Moon Spanner

7030-60042

E

I/C Valve Extractor

7034-60042

F

Blunt Edge Burnishing Tool

7035-60042

G

Spanner, Flywheel

7082-60042

H

Shop Pressure Gauge

7111-60042

I

Valve Base Spanner

16505-60042

J

Overpressure Valve Extractor

11048-60042

K

Overpressure Valve Cap Socket

780-CTG-66042

L

Graduated Glue Cup

2443-60042

M

Foot Pump (complete)

2229-60042

N

Foot Pump Hose

2219-60042

O

Round Brush, Metal 3/4"

7920-00-276-9507

P

Metal Valve Cap

2108-60042

Q

Crescent Wrench 12"

5120-00-293-0031

R

Channel Lock Pliers, Medium

5120-01-335-1564

S

Scissors, 10"

5110-00-596-9703

T

Drill Bit Set

5133-00-449-6775

U

Dremel Tool

5130-01-014-6856

V

Hammer

5120-01-032-7496

W

Pliers, Needle Nose

5120-00-184-9403

X

Hose, Water

4720-00-202-6482